In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features several new 3D printing partnerships and 3D printer deals, sustainability business news, bioprinter grants, and 3D printed glasses for dyslexic children.

Read on for the most recent updates from GE Additive, EnvisionTEC, Aspect Biosystems, Oerlikon, Airbus, Aconity3D, Granutools, STAC, and more.

3D printing partnership updates from Stratasys, Equispheres and Tempus 3D

Starting off this week’s partnership news is 3D printer OEM Stratasys, which has been awarded a contract extension by Airbus for the production of 3D printed polymer cabin interior components. The contract has now been expanded from the initial focus on production parts for Airbus’ A350 to include replacement and spare parts for maintenance, repair, and overhaul (MRO). The extension also includes parts for the aviation firm’s A300, A330, A340, and A320 aircraft platforms.

Meanwhile, Canadian additive manufacturing powder producer Equispheres has awarded two new projects as part of its lab expansion project, which it is supporting off the back of a $30 million fundraising round held last year. Equispheres has selected a 3D printer equipped with a 1000W laser from metal 3D printer manufacturer Aconity3D to aid in faster-printed part production, and has also acquired a GranuTools GranuCharge system which is designed to measure the electrostatic charge created within flowing powder.

“Normally the GranuCharge system is used to conduct basic research at academic institutions,” said Evan Butler-Jones, Director of Applications at Equispheres. “However, we use the tool as part of our QA process. Quality parts require quality powder and that requires precise instrumentation and measurement systems.

“The Aconity3D printer was chosen because of its increased precision, high configurability, and powerful 1000W laser. This printer enables us to conduct high-speed production parameter optimization research and testing.”

In more news from Canada, 3D printing service bureau Tempus 3D has announced a collaboration agreement with the Selkirk Technology Access Centre (STAC) to make more printing technologies and materials available to its customers. Focused on advanced manufacturing research, STAC’s capabilities include 3D printing, 3D scanning, rapid prototyping, materials research and development, and design services.

Tempus 3D CEO Robert Bleier, said: “We are excited to be partnering with the technology access centre, the technology and deep industry experience STAC has will expand our ability to meet our customers’ unique needs, and bringing us a competitive advantage in Canada’s additive manufacturing market, instantly placing Tempus 3D as a leading 3D printing service bureau in Canada.”

Oerlikon plans for climate neutrality by 2030

Swiss technology group Oerlikon, including its additive manufacturing branch Oerlikon AM, has published its first sustainability report within which it has pledged to become operationally climate neutral by the end of the decade. The group has selected eight of the 17 United Nations Sustainable Development Goals (SDGs) and put in place environmental, social, and governance targets for 2030, including using only energy from renewable resources and increasing the number of women in leadership roles within the company.

“Setting ambitious targets, such as achieving climate neutrality in our operations by 2030, clearly underlines our commitment,” said Dr. Roland Fischer, CEO of the Oerlikon Group. “We also intend to have 100 percent of our R&D investment in new products to cover the ESG criteria. We have always seen innovation and sustainability as interdependent – for example, in 2019, our innovative technology solutions for jet engines helped our customers in the aerospace industry save 25 million tons of CO2.”

New 3D printer acquisitions from Sintavia and PrintParts

Metal 3D printing service Sintavia has acquired three Arcam A2X electron beam printers from GE Additive, taking the company’s total number of electron beam 3D printers to seven. The latest purchases join Sintavia’s fleet of three Arcam Q20plus machines and one other A2X.

“It’s great to see continued momentum and innovation at Sintavia,” said Alain Dupont, Chief Customer Officer at GE Additive. “The recent addition of a third Q20plus printer, plus these three recently purchased A2X printers, means Sintavia now operates the largest fleet of Q20s and A2xs in the US. Precision aerostructure parts are a perfect fit for these machines, which were specifically designed for the cost-efficient production of large structural airframe components.”

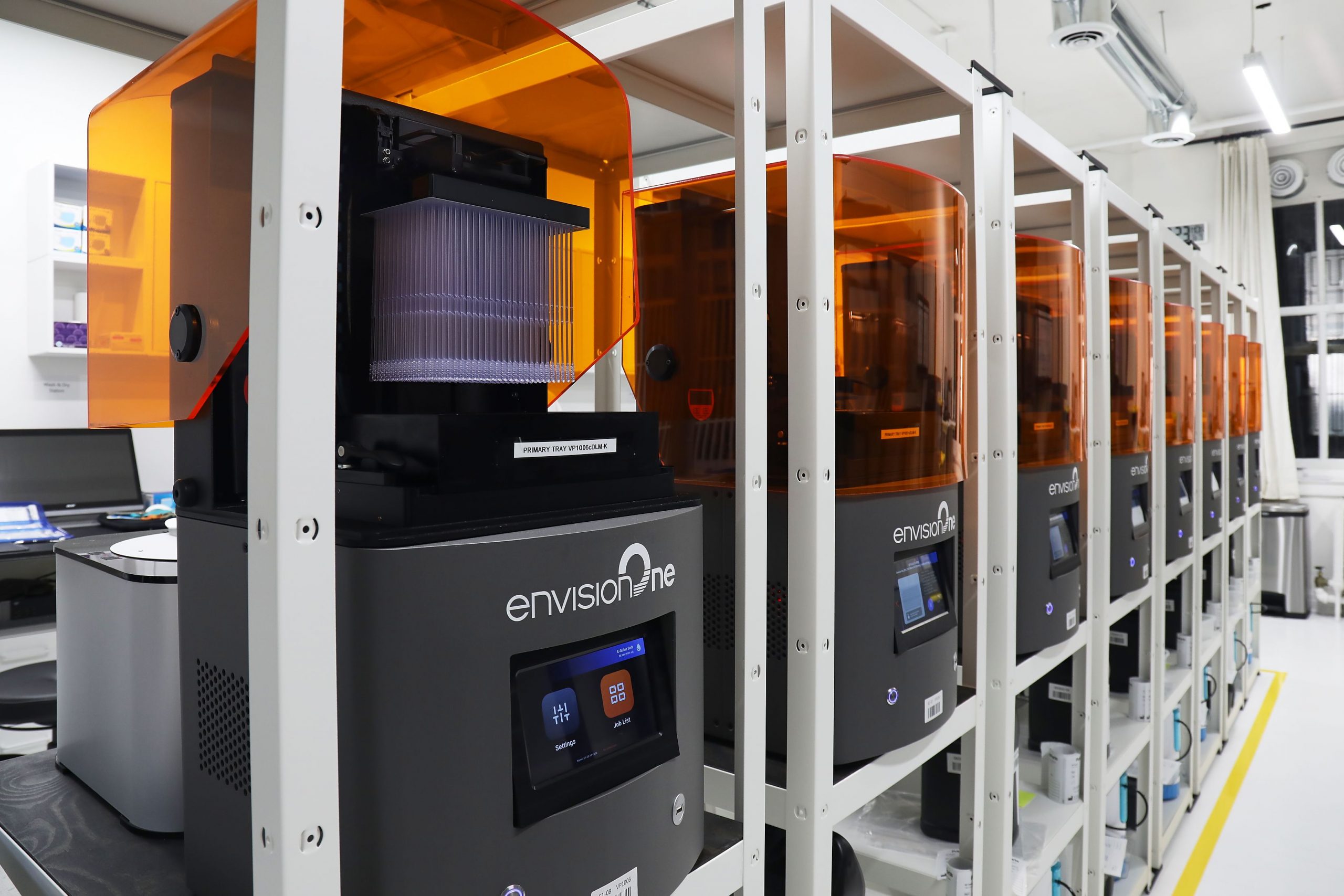

Elsewhere, 3D printing service provider PrintParts has announced the addition of eight Envision One cDLM industrial 3D printers from 3D printer and materials manufacturer EnvisionTEC. The addition considerably expands PrintParts’ production capacity and enables its customers to scale their 3D printing activities for production applications. Last year, PrintParts became the prime contractor for the New York City Government’s Covid-19 testing supplies and acquired the fleet of Envision One Systems to support the production of millions of nasopharyngeal (NP) swabs.

“We worked closely with EnvisionTEC as we developed our production strategy and we selected the Envision One system to expand our capacity to keep up with the demand for NP swabs,” said PrintParts Founder and CEO Robert Haleluk. “Moving forward, we are excited to apply this capacity to help our customers scale their additive manufacturing production with an amazing selection of industrial grade materials from EnvisionTEC and Henkel.”

Aspect Biosystems launches RX1 bioprinter grant

After the success of its previous grant program, Canadian 3D bioprinting company Aspect Biosystems has announced it is running its RX1 Bioprinter Grant Program again specifically for early-career Principal Investigators (PIs) and researchers planning to start a new lab within the next 12 months. The grant program will enable PIs access to Aspect Biosystem’s microfluidic 3D bioprinting technology in their labs, with selected applicants receiving an RX1 bioprinter at no cost for six months.

The deadline for applications is March 12 and those interested in applying can do so here.

HP MJF delivers 3D printed glasses to dyslexic children

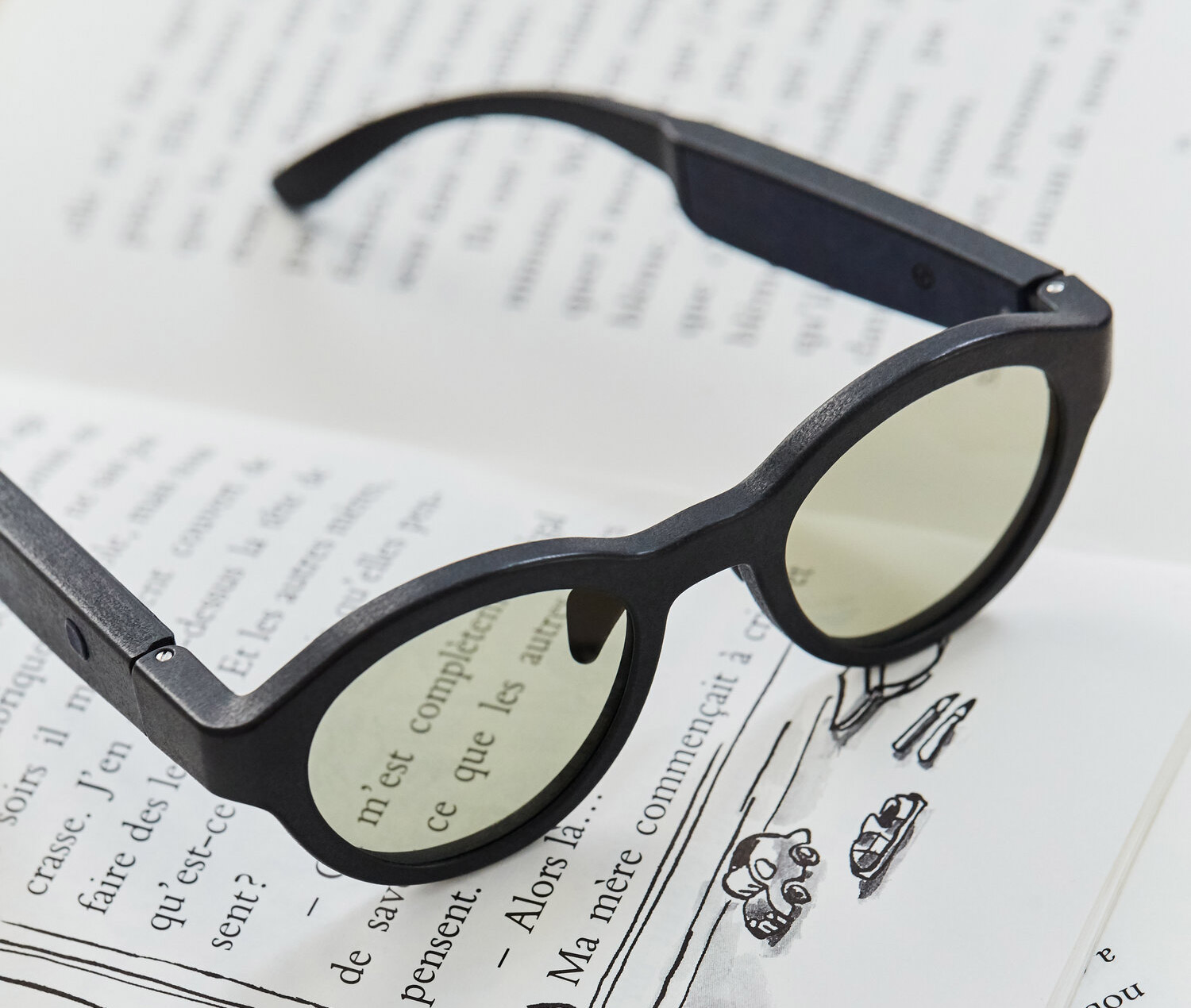

Abeye, a start-up company developed by French opticians Atol les Opticiens, has deployed HP’s Multi Jet Fusion (MJF) 3D printing technology to produce the frames for its Lexilens smart glasses, which are designed to make reading easier for dyslexic children.

The glasses are electronic and have acted and tinted lenses which filter out the mirror images that cause reading difficulties, activated by pressing a button on the frame. The Lexilens frame weighs just 35g and is printed entirely using MJF by French 3D printing service bureau Erpro before being assembled together with the lenses and other components.

“The manufacturing process for Lexilens 3D printed glasses is remarkable as it is the first printed multi-component product with such complex assembly,” said Emilio Juárez, EMEA Sales Director, HP 3D Multi Jet Fusion Business. “As there are no less than nine components, our partner Erpro’s expertise was extremely important in the context of developing multi-component products where assembly groups managed without comprising the quality of the final product.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Lexilens 3D printed glasses with the Sliced logo.