Launched October 2017, peel 3d is a sub-$6,000 handheld 3D scanner powered by Canadian scanning provider Creaform and American global electronics manufacturer AMETEK.

Boasting professional-grade quality at a competitive price tag, the device is targeted at customers simple, effective and more affordable 3D object capturing. As such, the peel 3d is designed to scan well without the need for sticky or external targeting points. It also uses white LED structured light technology, which is safe if exposed to the naked eye.

Quick, simple, effective calibration

First impressions of the peel 3d is that it is lightweight, facilitating long scanning session, and its calibration is fast and simple.

As with other 3D scanners of this price range, the peel 3d is calibrated using a board designed with multiple dots. In this instance, the scanner is place closed to the board and slowly moved away until a notification is received.

In peel 3d this calibration process takes about a minute to complete. Unlike other scanners in its range, the process is only conducted once with the dot-board flat on the ground/a table. Other scanners often require movement and slanting of the board to complete calibration. Further, for this process to be fully automated, you would be looking at a 3D scanner at around three times the price, so peel 3d’s solution is a welcome feature.

The software used for post processing 3D scans is also intuitive and simple to pick up.

peel 3d test parameters

Six objects, with varying surfaces and complexities, were 3D scanned using the peel 3d for the purpose of this review. All were performed in an office environment, with adequate overhead lighting. Most of the object were 3D scanned twice to find the optimal settings for each object. Parameters for each test 3D scan can be found in the table below.

| Object | Detection mode | Shutter speed | Resolution | Tracking dots |

| Test 1A Diadumenos Male Torso | Uniform surface | Automatic | 1mm | Y |

| Test 1B Diadumenos Male Torso | Uniform surface | 8 ms | 2mm | N |

| Test 2A Head of a Bearded Old Man | Uniform surface | Automatic | 1mm | N |

| Test 2B Head of a Bearded Old Man | Uniform surface | 8 ms | 2mm | N |

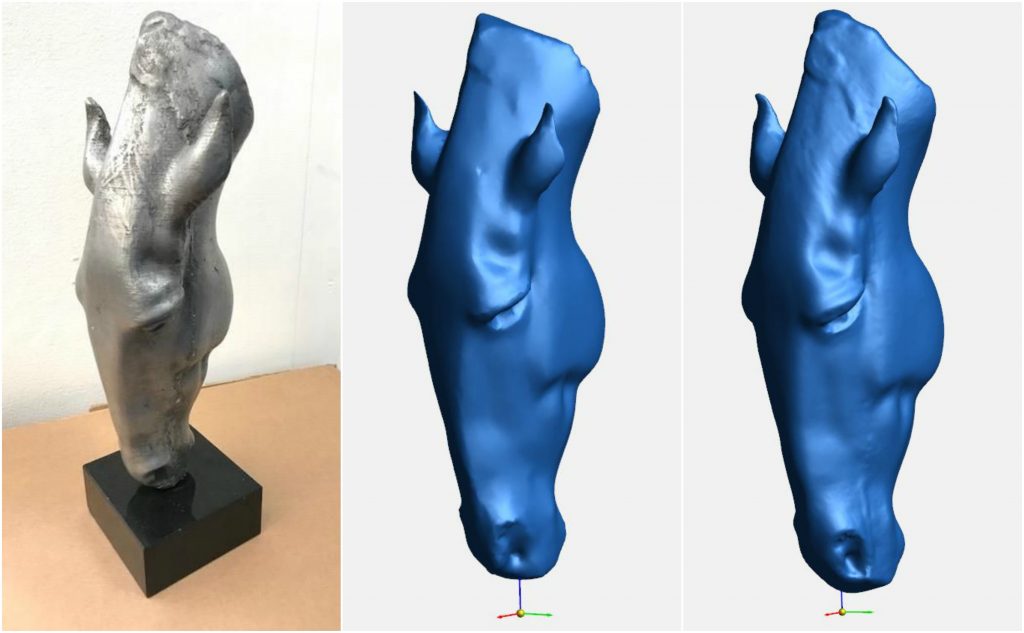

| Test 3A Marwari Horse Head | Automatic | Automatic | 2mm | N |

| Test 3B Marwari Horse Head | Uniform surface | 8 ms | 1mm | N |

| Test 4A Bust of Costanza Bonarelli | Uniform surface | Automatic | 2mm | N |

| Test 4B Bust of Costanza Bonarelli | Uniform surface | 1 ms | 1mm | N |

| Test 5 Living Model Head Scan | Automatic | Automatic | 2mm | N |

| Test 6 Wooden Chair | Uniform surface | Automatic | 2mm | N |

Basic 3D scanning

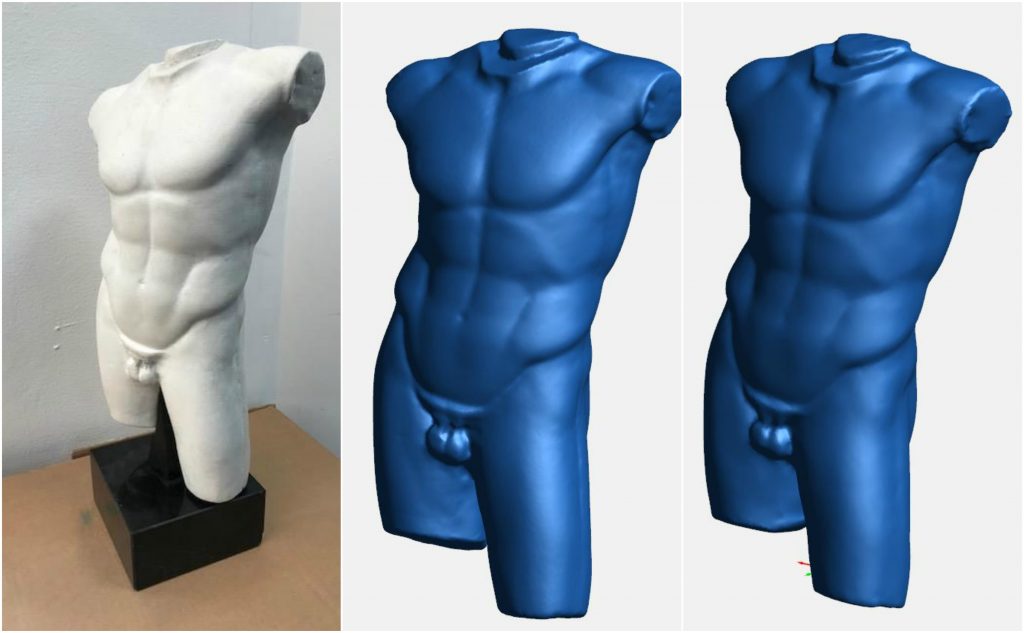

The first object was a 3D printed replica of the Diadumenos Male Torso sculpture displayed in the Louvre Museum, Paris.

Approximately 35cm high with large, smooth features, this model is a fairly simple test.

After Test 1A without tracking dots it became apparent that the peel 3d scanner could handle the model without them. This was proved in Test 1B, tried without tracking dots, and still achieving and adequate quality.

Capturing the full object in each test took around 2 minutes 30 seconds to complete. And both models required little to no cleaning after processing.

Capturing complex objects for cultural heritage

Next, we moved to more complex objects, with small and detailed features and, in one case, a reflective surface.

Tests 2A and 2B with the Head of a Bearded Old Man was captured well though some hard-to-reach portions around the neck had to be reconstructed after 3D scanning. Little unnecessary background content was captured in these sweeps. Our engineers were able to cut scan time from 8 mins to 2 mins by managing scanning parameters without compromising the model’s detail.

Tests 3A and 3B focused on a replica Marwari Horse Head sculpture which had been spray-painted silver giving it extra luster. For this sample, peel 3d’s uniform detection mode provided the best results, with a shutter speed of 8 ms. Test 3B of the Marwari Horse Head, arguably the better quality of the two tests, was captured in only 4 minutes 20 seconds.

And, in a final test of complexity the team tried a replica 3D printed Bust of Costanza Bonarelli. Scan Test 4B of this model proved to be the better quality of the two, though it required 27 minutes of post-processing against 4A’s post-processing time of 6 minutes 20 seconds. The trade of here was with scan time. Neither test took longer than 4 mins to complete, but subsequent digital steps are required to finish the model to a high detail.

3D scanning at scale and for live models

The final test performed in our review examined peel 3d’s ability to capture large objects and living models, as is so commonly done using 3D scanning.

A full scale chair, was used to investigate the peel 3d’s potential for industrial applications. This object proved more challenging for the device, and the thin features meant it took 30 minutes of scan time.

The head scan of a live model was also tricky to complete, due to fine features like hair. For the completion of the scan we asked our volunteer to wear a hood. The overall shape and key features of the face were captured well.

peel 3d delivers on its promises

In summary, with quick calibration, easy to use software and rapid capture times, the peel 3d is a very user-friendly device. It gives reasonable results in a short time, even with small complex objects, and the automatic parameters are powerful.

As a caveat with many handheld 3D scanners of this price range, tracking of the object does sometimes get lost. However, peel 3d makes it reasonably easy to resume a scan when this occurs.

The peel 3d delivers on what is promises and would be a perfect choice for a beginner or maker looking for an affordable entry into quality 3D scanning.

For all the latest 3D printing news and reviews subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows the peel 3d handheld 3D scanner. Photo by Oscar Milani Gallieni