The Copymaster 3D 300 is a sub $1,000 (or sub £500) FFF/FDM system from UK-based 3D printer provider Copymaster 3D. With a build area of 300 x 300 x 400 mm the Copymaster 3D 300 is a larger-than-average desktop system, offering ample build volume for industrial, prototyping and functional 3D printing applications.

The 3D Printing Industry engineering team performed a detailed review of the Copymaster 3D 300’s features and how the printer performed a range of tasks appropriate to the intended application. Read on for the results and to find out if this low-cost desktop 3D printer is good value.

Setup and filament detection

The Copymaster 3D 300 is a pre-assembled 3D printer, meaning that the minimal remaining initial setup was a straightforward task. Accordingly, the engineering team determined that is was almost impossible to incorrectly assemble the system.

The process involves following guide holes and reference points to help in attaching the build plate and loading a spool of filament. The build plate of the 3D printer is magnetic, making it easy to remove, and flexible to facilitate part removal after printing. Both of these features proved very useful throughout testing.

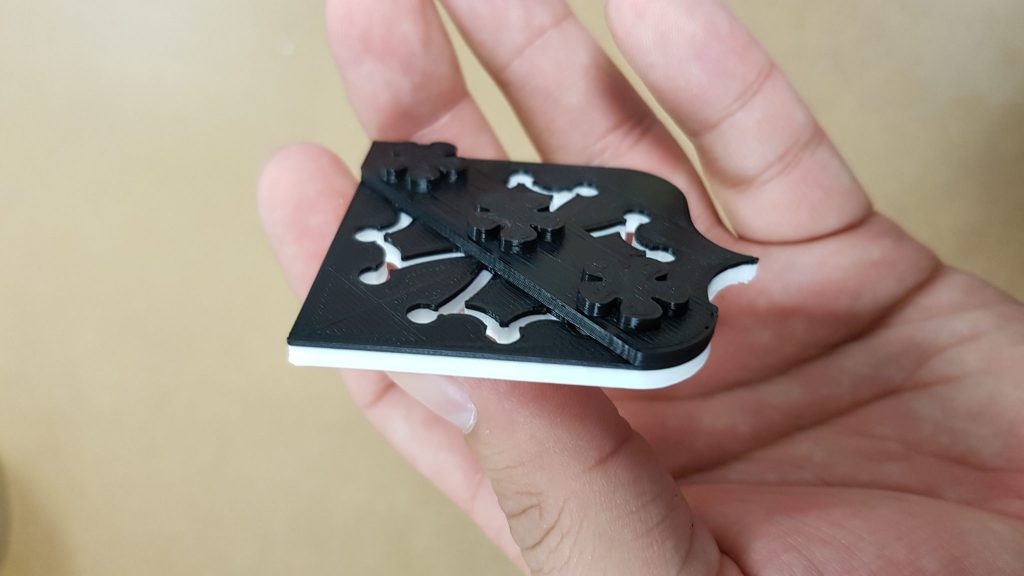

The Copymaster 3D printer also has an in-built filament detector which automatically pauses the system when filaments runs out or breaks. Our engineers tested this capability by 3D printing a sample object in two filaments with different colors but the same print settings. The result is incredibly neat, and restarting the print proved no problem for the Copymaster 3D 300.

Print quality

According to technical specifications provided, the Copymaster 3D 300 offers a Z accuracy to 50 μm. The models detailed in the table below were selected to test the print quality.

| Model | Scale (%) | Layer height (mm) | Speed (mm/s) | Bed temperature (°C) | Print temperature (°C) | Infill (%) | Support |

| Bust of Napoléon | 100 | 0.2 | 50 | 60 | 205 | 15 | Touching build plate |

| Michelangelo’s Pieta | 80 | 0.15 | 50 | 60 | 205 | 15 | Everywhere |

| The Thinker by Rodin | 80 | 0.1 | 50 | 60 | 205 | 15 | Everywhere |

All surfaces of the tested 3D prints were smooth and captured excellent details of the original models. A variety of layer heights were tried, and 0.15 mm proved to be the optimal parameter in the trade-off between quality and speed.

The lower layer height of 0.1 mm however, as seen in The Thinker model, was almost perfect. The only notable defects in this test 3D print were due to artifacts left by support removal.

We experienced no problems when 3D printing each of these models, and the quality achieved was impressively high for each model the Copymaster 300 handled.

In a further quality test, the team assessed the extruder’s retraction ability. A vase designed with lattice-like walls requires the 3D printer to rapidly extrude and retract filament. In the finished article no wires or stringing can be observed between the gaps of the vase’s intricate latticework.

Functional 3D printing and making use of the build plate

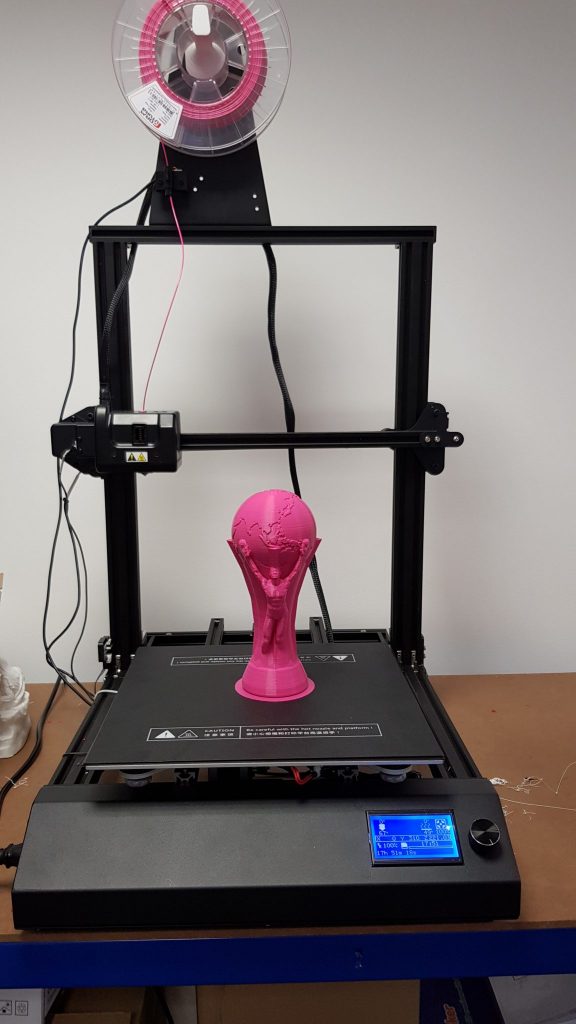

To further explore the Copymaster 3D 300’s large build area, our team 3D printed a replica World Cup trophy, and a plaque displaying the emblem of the City of London. The replica trophy made use of the 3D printer’s build height (up to 400 mm) and the plaque reached across the build plate. Both models were reproduced at a high quality without error.

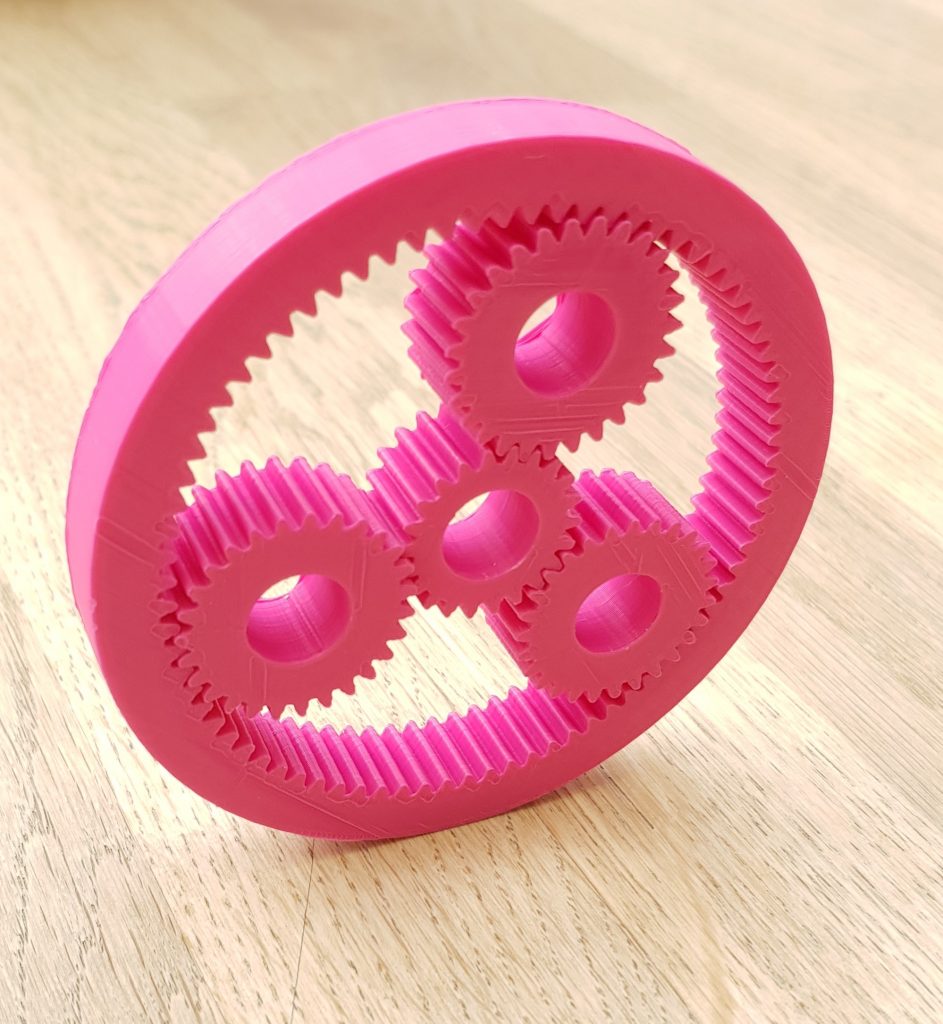

To assess functionality in terms of various applications, the engineering team 3D printed a medical model, a mechanical component, and functional/moving gears. A large bone model, screw and nut, and planetary gear all achieved great results.

As required, the bone has a smooth surface finish and again makes use of the machine’s build area.

Printed side by side, the screw and nut fit together perfectly without the need for finishing or much force.

And the planetary gears move easily when removed from the build plate.

Overview of the Copymaster 3D 300

In summary, the Copymaster 3D 300 offers a high print quality that opens up many possible 3D printing applications. Due to its size, the system is suitable for an industrial setting, making prototypes and functional mechanisms. The impressive quality of the prints from this machine also lend it to projects that require a high level of detail, such as medical models and replica sculptures for an education setting, or representative product development.

The system requires no technical knowledge for set up, and was a pleasure to use. Features like the magnetic and flexible build plate, and the filament detector are a handy bonus that add to the overall user friendliness of the machine.

At an attractive price, we believe this 3D printer offers good value for money, and has the potential to become an efficient tool for a variety of workshops.

The Copymaster 3D 300, alongside the larger Copymaster 3D 400 and Copymaster 3D 500 models are available to buy directly from Copymaster 3D here.

For all the latest 3D printing news and reviews subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows the Copymaster 3D 300 3D printer.