Researchers from the University of California Los Angeles’ Samueli School of Engineering have developed a novel two-pronged process to enhance the strength of hydrogels that could be used to create artificial tendons, ligaments, and cartilage.

The constructed synthetic biomaterials mimic the structure, stretchiness, and durability of natural biological tissues, and their flexibility means they could be 3D printed in previously unachievable configurations.

“This work shows a very promising pathway toward artificial biomaterials that are on par with, if not stronger than, natural biological tissues,” said study leader Ximin He, an assistant professor of materials science and engineering at the UCLA Samueli School of Engineering.

Fabricating stronger hydrogels

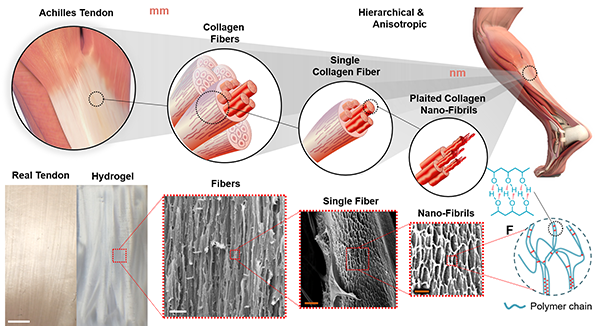

The interior structures of hydrogels consist of crisscrossing polymers or gels, and they show promise in biomedical applications such as replacement tissues and within soft robots and wearable electronics. However, current synthetic hydrogels are not yet strong or durable enough to adequately replace tissues that need to move and flex repeatedly while bearing weight.

To solve this, the UCLA researchers developed a two-stage process that combined molecular and structural engineering to create hydrogels with a toughness ten times that of natural tissues. They chose an FDA-approved polyvinyl alcohol material to make their hydrogel prototype.

First, they embarked upon a method called freeze-casting, which is a solidifying process that creates porous and concentrated polymers, comparable to that of a sponge. They then applied a salting-out treatment to crystalize the polymer chains into strong fibrils. The combination of these two processes forms a series of connecting structures spanning molecular to millimeter levels within the hydrogels, making them stronger and more stretchable.

To test the new hydrogels’ durability, the researchers carried out 30,000 cycles of stretch testing, throughout which the material provided no signs of deterioration.

Greater flexibility for 3D printing

During their study, the UCLA team achieved new hydrogel structures with not only improved strength, but also greater flexibility. They believe this could enable the 3D printing of hydrogels in configurations that have been previously unachievable.

The researchers also demonstrated that such 3D printed structures could potentially be transformed into different shapes by altering aspects such as temperature, acidity, or humidity. Through this, the hydrogels could potentially act as artificial muscles capable of exerting substantial force and exhibiting high resilience.

With their enhanced strength, durability, and flexibility, the new hydrogels are suited to biomedical applications such as artificial tendons, ligaments and cartilage. Not only this, but they could also show promise in the field of surgical machines and bioelectronics.

Further details of the study can be found in the paper titled “Strong tough hydrogels via the synergy of freeze-casting and salting out” published in the Nature journal. The paper is co-authored by M. Hua, S. Wu, Y. Ma, Y. Zhao, Z. Chen, I. Frenkel, J. Strzalka, H. Zhou, X. Zhu, and X. He.

Advancements in 3D printed hydrogels

A plethora of research is currently underway within the field of 3D printed hydrogels as scientists seek to make them stronger, tougher, more durable and increasingly flexible to widen the scope of their applications.

In recent months alone, a novel method of 3D printing hydrogels into other polymers to create complex hybrid microstructures has been developed, while a Spanish-led research team has 3D printed a hydrogel capable of accelerating the production of T-cells in cancer patients. Elsewhere, scientists have embarked upon developing a new method of 3D printing tunable viscoelastic materials using cellulose-based hydrogels, to provide parts with multidirectional stiffness gradients.

Most recently, researchers from Rutgers University created light-sensitive 3D printed artificial ‘muscles’ that can alter their shape and appearance on demand. The robotic devices are based on a novel hydrogel inspired by squid, octopus, and cuttlefish cells.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows enhanced microscopic photo shows the artificial tendon material developed by UCLA materials scientists. True scale of image is 1 cm in width. Image via UCLA.