Researchers from Rutgers University have created light-sensitive 3D printed artificial ‘muscles’ that are capable of fluctuating their appearance and shape on-demand.

The robotic devices are based on a novel hydrogel, that’s inspired by the adaptable cells found in squid, cuttlefish and octopuses. Once exposed to a light stimulus, the stretchy material is able to contract and change color, potentially providing it with applications in consumer electronics or even military camouflage in future.

“Electronic displays are everywhere and despite remarkable advances, they’re based on rigid materials, limiting the shapes they can take,” said lead author of the study Howon Lee. “Our research supports a new engineering approach featuring camouflage, that can be added to soft materials and create flexible, colorful displays.”

Additive inspiration under the sea

Octopuses are similar to chameleons in that they’re able to reversibly change their skin tone or texture to match their surrounding environment. For these sea creatures and their cephalopod cousins, the mechanism is either used for communication or to evade predators, but the behavior has also drawn interest from researchers.

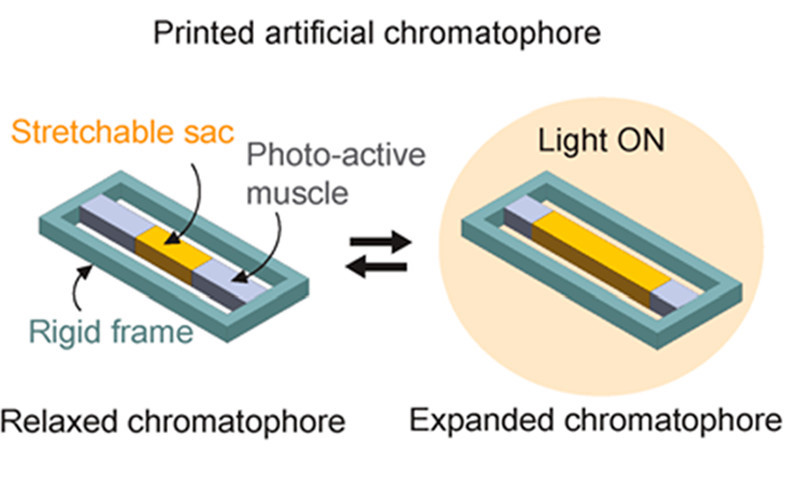

Previous studies have found that octopuses owe their unique abilities to thousands of light-reflecting cells called chromatophores, that grow naturally on their skin. Although the mechanism isn’t fully understood, scientists do know that the cells are attached to muscles that once stretched, open sacs containing colored pigments.

While cephalopod-inspired color modulation has been attempted before, the sensing and actuating functions of replicas have often been conducted separately. As a result, these squid-based devices feature bulky, complex control systems, that emit the magnetic signals needed to trigger the color-changing mechanism.

With their Light-responsive Artificial Chromophores (or LACs), the Rutgers team sought to overcome this by creating a fully-integrated adaptable device. In order to achieve this though, the engineers would need to design a novel reactive hydrogel, that once photocured, would yield a material capable of on-demand actuation.

The engineers’ disguisable devices

During their study, the team developed a ‘smart gel’ composed of a polymer loaded with nanoparticles, that was capable of turning light into heat energy, and forcing actuation to occur. Using their new material, the team was able to print a light-responsive muscle for their LAC, which also featured a ‘sac’ and rigid outer frame.

Once assembled, the device demonstrated the ability to sense and actuate to four different projection patterns, opening its replica sac within two minutes. The level of response shown by the LAC also proved that it was capable of sophisticated reactions, and could be modulated to settings in between ‘on’ and ‘off.’

Despite the level of fidelity exhibited by the LACs, connecting three together did cause some ‘thermal leaking’ to occur between them. Similarly, the Rutgers team acknowledged that the devices’ speed, sensitivity, and durability could be improved with further research, but considered their broader approach to be a success.

While the engineers only tested monochrome dyes, they see no reason why other colors couldn’t be added to the device’s sac in the future to enable novel applications. Using brighter colors, they suggested, could make it ideal for printing displays, while terrain-based shades might provide soldiers with camouflage from their enemies.

3D printed creature-based creations

Although the Rutgers team’s approach is unique, they’re far from the first researchers to 3D print soft robotic devices based on mechanisms found in the natural world.

Scientists based at Cornell University have also been inspired by cephalopods, and 3D printed a replica octopus tentacle with a life-like muscle arrangement. Using an elastomer as a base allowed the team to fabricate objects with greater design freedom, and achieve more complex shapes than was previously possible.

Researchers at the Georgia Institute of Technology, meanwhile, have based their robot on a warm-blooded mammal instead, and 3D printed an energy-efficient ‘SlothBot.’ The device is currently being used above the Atlanta Botanical Garden, where it’s monitoring the animals, plants, and environment below.

Elsewhere, another team from Cornell has taken inspiration from much closer to home, and 3D printed a robotic muscle that’s capable of ‘perspiration.’ The device’s soft, fingerlike actuators enable it to retain water, which can later be used to prevent itself from overheating during prolonged use by ‘sweating.’

The researchers’ findings are detailed in their paper titled “Multimaterial Printing for Cephalopod-Inspired Light-Responsive Artificial Chromatophores.” The research was co-authored by Daehoon Han, Yueping Wang, Chen Yang, and Howon Lee.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an octopus with brightly colored chromatophore cells. Photo via the NOAA Okeanos Explorer Program.