Researchers from Cornell University, Ithaca, New York, have developed a 3D printed soft robotic muscle capable of controlling its internal temperature through perspiration.

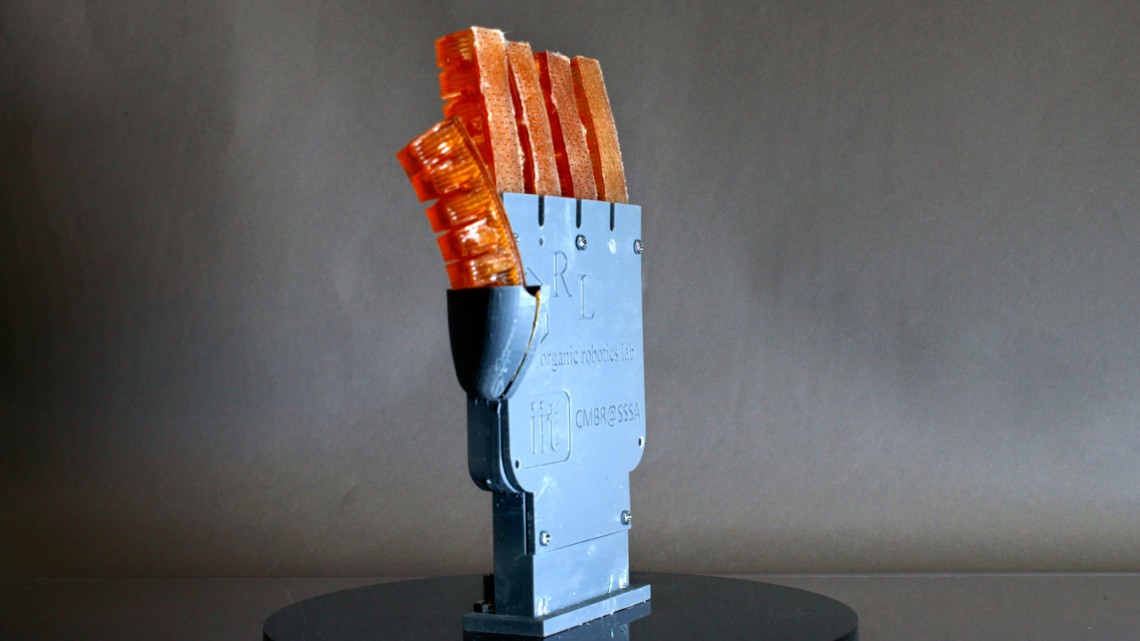

Using hydrogel-based composite resins and stereolithography (SLA), soft, fingerlike actuators were produced that can retain water and respond to temperature. According to Robert Shepherd, associate professor of mechanical and aerospace engineering, this bioinspired form of thermal management could enable untethered robots to operate for longer periods of time.

“Sweating takes advantage of evaporated water loss to rapidly dissipate heat and can cool below the ambient environmental temperature,” said T.J. Wallin, a research scientist at Facebook Reality Labs, and co-lead author of this study, published in Science Robotics. “So as is often the case, biology provided an excellent guide for us as engineers.”

Breaking a sweat

As stated by Professor Shepard, who led this project, one of the hurdles for making durable, agile, soft robots is managing its internal temperature as exothermic engines tend to overheat. Moreover, synthetic materials used within soft robots, hold heat, whereas metals, dissipate heat quickly. There, the researchers sought to make a natural cooling system that would not add weight or limit the design of a soft robot.

The customized hydrogel-composite resins were used to additively manufacture the finger fluidic elastomer actuators with pores that autonomically open and close in response to thermal fluctuation. The pores dilated at increased temperatures which released water that yields a cooling rate over 600% faster than similar non-sweating devices.

“The best part of this synthetic strategy is that the thermal regulatory performance is based in the material itself,” stated Wallin. “We did not need to have sensors or other components to control the sweating rate. When the local temperature rose above the transition, the pores would simply open and close on their own.”

Self-cooling robots

Following several gripping tests, the researchers found that the autonomous sweating deterred the robot from overheating, however, it did make it’s surface slippery. Thus, modifications to the hydrogel texture will be made. In addition, the robot’s ability to secrete fluids could also lead to methods for absorbing nutrients, catalyzing reactions, and removing contaminants.

“I think that the future of making these more biologically analogous materials and robots are going to rely on the material composition,” added Professor Shepherd. “This brings up a point [about the importance of] multidisciplinary research in this area, where really no one group has all the answers.”

“Autonomic Perspiration in 3-D Printed Hydrogel Actuators“ is co-authored by Anand K. Mishra, Thomas J. Wallin, Wenyang Pan, Patricia Xu, Kaiyang Wang, Emmanuel P. Giannelis, Barbara Mazzolai, and Robert F. Shepherd.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a 3D printed soft robot muscle that can regulate its temperature through sweating. Clip via Cornell University.