Researchers from the University of Stuttgart have 3D printed a tiny spectrometer mountable directly onto smartphone cameras, providing them with hyperspectral imaging capabilities.

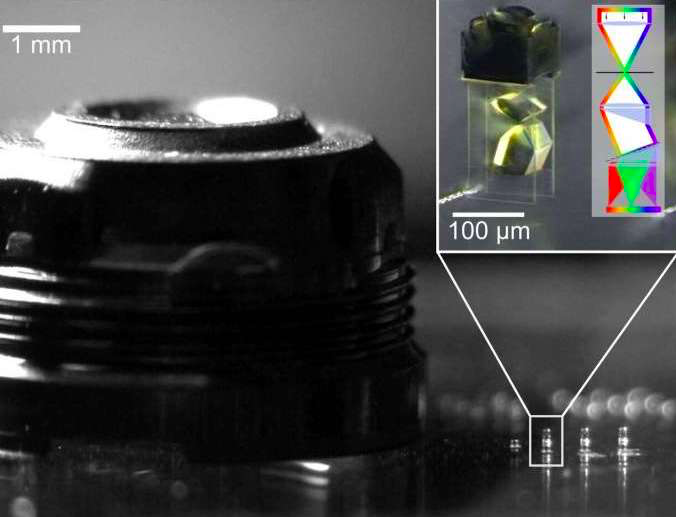

By combining two-photon photopolymerization (2PP) and a super-fine inkjetting process, the team were able to create a tiny measurement device, with a volume of just 100 x 100 x 300 μm3. The novel instrument features tailorable high-frequency grating and strong dispersive qualities, potentially making it ideal for imaging within size-critical medical procedures, or as an add-on for consumer electronic devices.

Re-inventing the spectrometer

2PP 3D printing has come on leaps and bounds since the early 2000s, progressing from creating basic microlenses to complex waveguides, collimators and diffractive optical devices. The technology now provides scientists with a method of precise millimetre-scale production, and led to a experimental race between them, to create miniaturized products with unique functionalities.

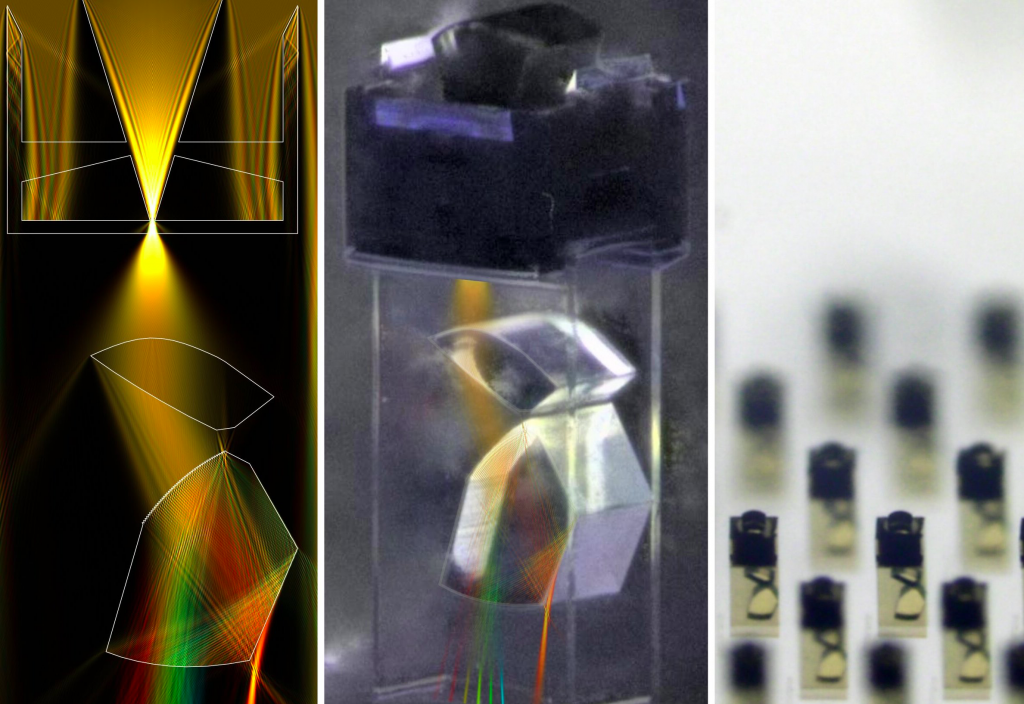

In the past, a number of different 3D printed mini-spectrometers have been developed and commercialized, with many featuring the same ‘direct imaging’ technology. Essentially these tiny instruments create a spatial-spectral response by redistributing incoming light, which can then be measured by an imaging sensor and converted into a reading.

However, while the technology itself is well-established, the Stuttgart scientists have now sought to go even smaller, producing a device that’s two times tinier and three times more accurate than its competitors. The advantages of such a device could prove significant, allowing it to be mounted to everyday smartphones, and used for anything from skin disease diagnosis to counterfeit banknote detection.

A smartphone-ready spectrometer

The researchers initially designed their spectrometer in two separate parts: a light collector and dispersing imager, before transferring it to SolidWorks, and adding lens mounts and an ink basin to its surface. Once the team had fully-optimized their design, they deployed a Nanoscribe GT2 3D printer to fabricate their first prototype.

To provide the resulting device with the necessary sensing capabilities, the scientists then utilized an SIJ-S030 inkjet printer, to fill its ink basin and give it a dispersed ‘slit image plane.’ During ray tracing simulations, in which a light beam was shone through the spectrometer’s aperture, its slit proved capable of serving as an imaging lens, separating wavelengths and relaying them to a nearby sensor.

Utilizing 3D printing to create the mount and lens simultaneously, was found to provide them with near-perfect alignment, and allowed the device to operate in the 490 nm to 690 nm range. The micro-tool also featured a spectral resolution of 17.8 ± 1.7 nm at 633 nm, but the team believe that using an iterative reconstruction algorithm, this could be sharpened further to enable novel end-use applications.

For instance, the scientists concluded that their spectrometer is capable of being “integrated almost non-invasively into a smartphone,” turning it into a hyperspectral camera. Given that the likes of Huawei have integrated monochromatic sensors into their recent devices, the researchers have surmised that their microscopic creation has significant mass-market potential.

2PP and high-precision 3D printing

Using 2PP 3D printing, it’s now possible to create ultra-precise optics, but the technology has also been applied to develop novel medical micro-structures.

Nanoscribe recently worked with scientists from the University of Freiburg to refine its 2PP 3D printing process, and create high-res miniature glass micro-devices. The optimized printing, debinding, and sintering process could be deployed in future to produce next-generation biomedical instruments.

On a more experimental note researchers from ETH Zurich have 2PP 3D printed drug delivery microbots that are capable of ‘swimming’ in human blood vessels. The team’s novel multi-material devices have the potential to be injected directly into future patients, and controlled using magnetic fields.

In a similar approach, researchers from the University of Grenoble have 2PP 3D printed a millennium falcon that’s controllable using deformable magnetic fields. By integrating magnetic microbeads into a conventional polymer, the team found they were able to achieve various stages of remote actuation.

The researchers’ findings are detailed in their paper titled “3D-printed miniature spectrometer for the visible range with a 100 × 100 μm2 footprint. ” The study was co-authored by Andrea Toulouse, Johannes Drozella, Simon Thiele, Harald Giessen and Alois Herkommer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a smartphone camera lens. Photo via the Light: Additive Manufacturing journal.