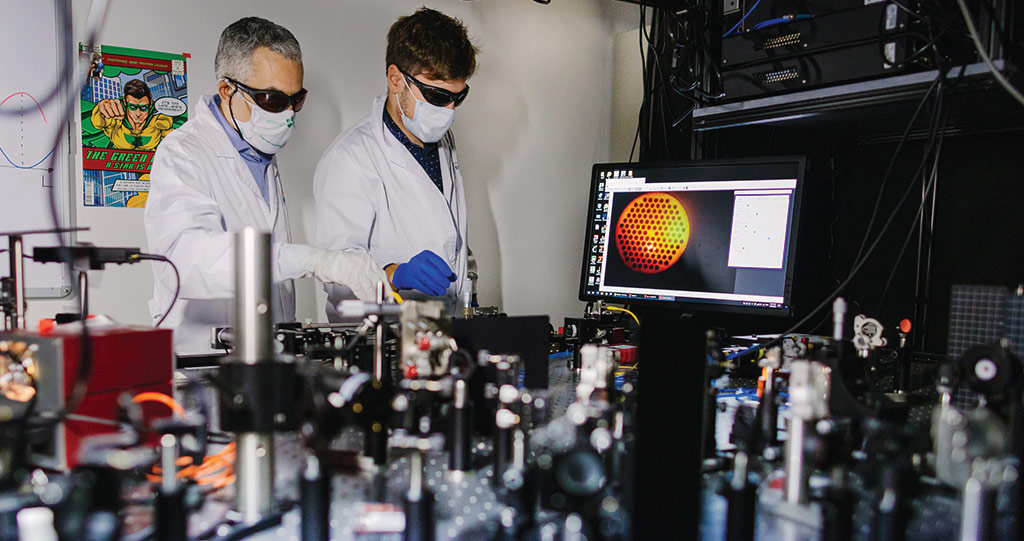

Researchers from the King Abdullah University of Science and Technology (KAUST) have developed a new method of 3D printing photonic crystal fibers – a special type of optical fiber.

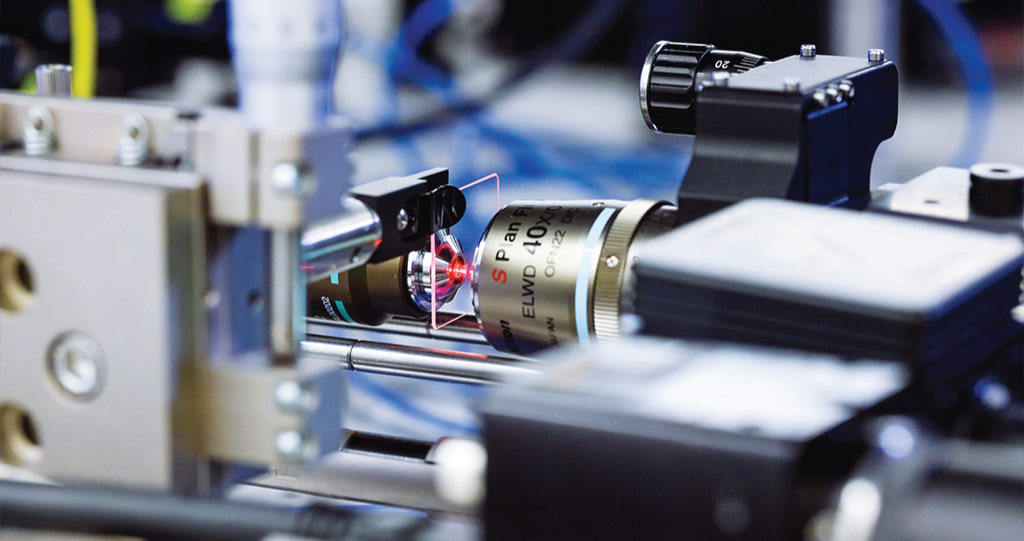

The team constructed a purpose-built SLA-based 3D printer for the project, one that enabled the scientists to customize their optical fibers with previously impossible internal geometries. Much like any resin-based system, it works by curing photopolymers into solid parts layer by layer, except it grants “unprecedented ease and precision” while fabricating fiber structures at much higher speeds than traditional manufacturing processes.

What are photonic crystal fibers?

Fiber optics technology is capable of transmitting information at lightspeed. As such, it is the driving force behind a whole host of modern technologies, including medical imaging devices, military communications systems, and of course high-speed internet.

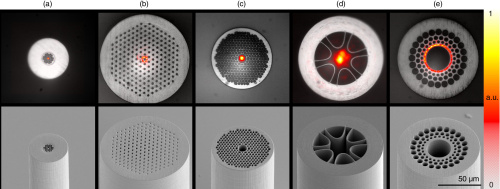

Photonic crystal fibers (PCF) are a subclass of optical fiber that emerged at the University of Bath in 1996. PCFs are special in that they feature several internal channels that run along the entire length of the fiber. The channels act like near-perfect mirrors, improving the fibers’ light trapping and long propagation properties. This ultimately means a faster rate of transmission and a reduction in information loss.

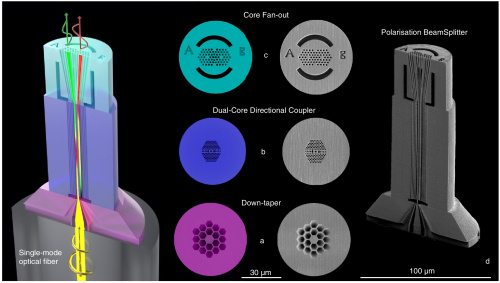

“Photonic crystal fibers allow you to confine light in very tight spaces, increasing the optical interaction,” explains Andrea Bertoncini, a co-author of the study. “This enables the fibers to massively reduce the propagation distance needed to realize particular optical functions, like polarization control or wavelength splitting.”

Using 3D printing to modify optical properties

The primary method of tuning a PCF’s optical properties is to modify its cross-sectional geometry. This is done at the initial manufacturing stage, where the fibers are conventionally drawn out from a pool of molten silica glass. Factors that can influence a fiber’s properties include the size and shape of the hollow chambers, as well as the cross-sectional pattern itself.

Since the diameter of an optical fiber is often a fraction of a millimeter, the patterns are usually drawn out in scaled-up versions of the fibers first. While this works, it introduces limits to the number of geometries that are possible due to factors such as gravity and surface tension.

“Photonic crystal fibers offer scientists a type of ‘tuning knob’ to control light-guiding properties through geometric design,” adds Bertoncini. “However, people were not fully exploiting these properties because of the difficulties of producing arbitrary hole patterns with conventional methods. The surprising thing is that now, with our approach, you can fabricate them. You design the 3D model, you print it, and that’s it.”

By 3D printing the PCFs instead, the KAUST team was able to overcome these geometric limitations. Custom cross-sectional areas were programmed directly into the fiber layers themselves, eliminating the need to work with scaled-up versions altogether.

According to Bertoncini, the novel process also allows for multiple cross-sectional areas to be fabricated along a single optical fiber – a feature that would otherwise be impossible. The technique can be used to split a light beam into its individual polarization components, much like a prism does to a ray of white light. Multiple cross-sectional areas can also be used to vary the focus of a light beam as and when needed, paving the way for a whole new method of high-speed, highly-custom optical fiber production.

Further details of the study can be found in the paper titled ‘3D printed waveguides based on photonic crystal fiber designs for complex fiber-end photonic devices’. It is co-authored by Andrea Bertoncini and Carlo Liberale.

3D printing for optics applications

The 3D printing of optical devices is a cutting-edge sector within additive manufacturing. Luxexcel, a specialist in 3D printed prescription lenses, recently partnered with waveguide manufacturer WaveOptics to 3D print prescription smart glasses with augmented reality (AR) functionality. The upcoming lens modules will combine Luxexcel’s lenses with WaveOptics’ waveguides and light projectors, providing smart technology in a normal form factor that can be integrated with off-the-shelf eyewear frames.

Elsewhere, engineers from 3D printer OEM Nanoscribe and the University of Freiburg recently collaborated to 3D print high-resolution glass silica microstructures using two-photon-polymerization (2PP). The optics are made of a glass-like resin called ‘Glassomer’, and feature a surface roughness of just 6 nanometers, much less than the 40-200 nanometers seen in many conventionally manufactured glass parts. The scientists believe their 3D printing process could be used to produce the next generation of micro-optics with potential applications in medical imaging systems.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a set of highly-custom 3D printed optical fibers. Photo via KAUST.