Say you’re a company that develops CAD software for 3D printing and a new printer comes out – we’ll call it the Connex3 – that prints with a wide gamut of colours. What would you do? Well, if you know what you’re doing, you’d probably be pretty quick to update your software to accommodate these new developments. That’s what MachineWorks, makers of CAD software Polygonica, seems to have done.

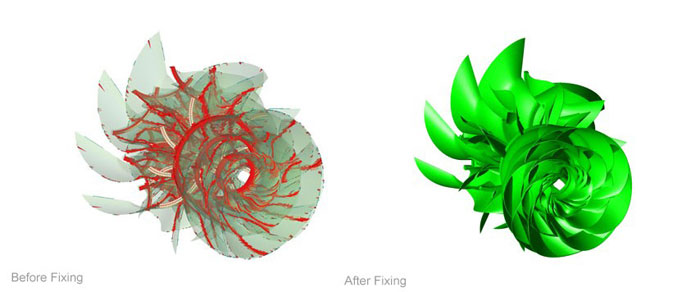

MachineWorks’ Polygonica is software typically used to repair meshes for 3D printing. The Polygonica 1.1 update enhances the software’s healing and boolean algorithms to increase the speed and overall capability of the software to repair a given mesh. More importantly, with Polygonica 1.1, the company may be responding to Stratasys’ latest release, the multicolor and multimaterial Connex 3. Because the .stl standard format for 3D printing is limited in terms of colour-processing, the new software update allows Polygonica to read other, more colour-friendly file formats, like .obj, .amf, and .3ds. While performing repair operations, like sealing a model, erasing self-intersections, non-manifold faces, and noise shells the colour data remains in tact. The new software also allows meshes to be sliced at any resolution into vector and image slice formats.

In addition to prepping for the coming colour revolution, the update makes it to possible to process large solids with its automatic simplification for out-of-core solids. Files of over 40GB in size can be processed with the new software and the maximum size of the mesh is only limited by your disc space. MachineWorks claims that the size of your file has no impact on the performance or stability of the repair of your models.

Though the Connex3 is a significant achievement for industrial 3D printing, 3D Systems also announced the release of the CubeJet color-jet 3D printer for about $5,000 with other higher grade machines and, of course, the Mcor Iris prints in full colour, using paper. MachineWorks seems keen to get ahead of the movement towards increased colour printing. Dr. David Knight, Polygonica Sales Manager, says, “The new release of Polygonica represents a leap forward in solid modelling. The ability to heal and slice colour meshes is important in the 3D Printing industry, where full colour printing is becoming more commonplace. Additionally, preserving arbitrary data on meshes, as well as handling very large models, is important for other industries such as Computational Fluid Dynamics (CFD, Finite Element Analysis (FEA) and Reverse Engineering.” If other CAD software developers want to keep pace with the advances taking place in 3D printing technology, they may want to follow suit.

Source: Polygonica