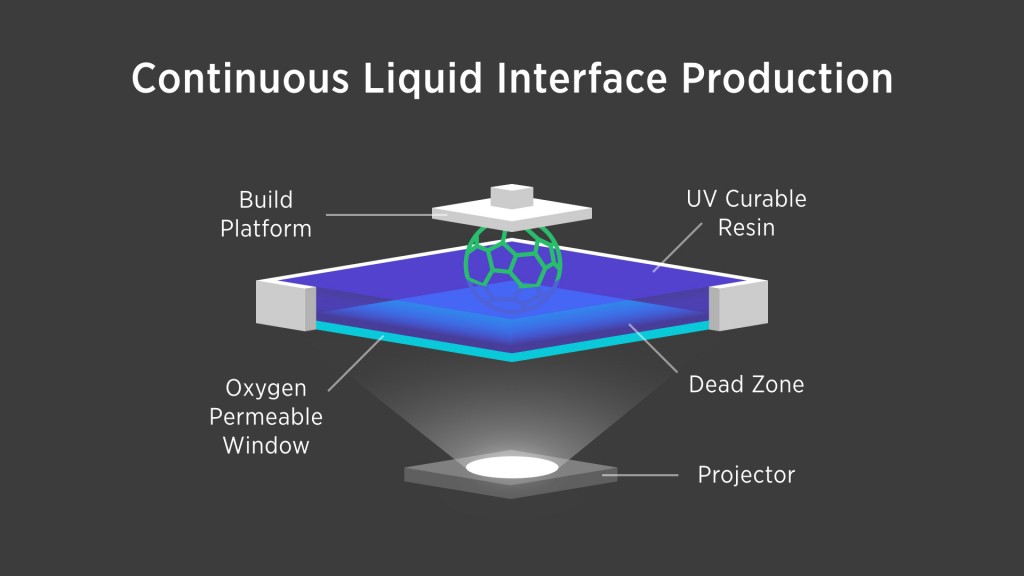

Joseph DiSimone, CEO and Co-Founder of Carbon3D, gave a presentation to introduce a photochemically tunable DLP 3D printer that prints 25-100x faster than existing 3D printers at TED 2015. As a result, Autodesk invested 10 million dollars from their Spark Investment Fund in the company earlier this year and, later, Alan Mulally, former CEO of Ford Motors joined their board of directors. Now, Carbon3D has released some news about one of its early adopters: Legacy Effects.

At the 2015 Additive Manufacturing Users Group (AMUG) conference, Jason Lopes, the Lead Systems Engineer of Legacy Effects, saw Carbon3D’s CLIP technology and was impressed. Lopes said of the encounter, “Right away I was attracted because of the quality of the parts they were showing me, and the speed at which they were able to produce parts with final-part mechanical properties.” Carbon3D offered to send Jason back to Legacy Effect headquarters with a fresh Carbon3D prototype and membership to their early access program. Jason was skeptical, probably because of the ridiculous amount of hype generated around 3D printers, especially at conferences.

“In this industry, you want to believe everything you hear, but you have to pull back and ask more questions,” he said. The team at Carbon3D worked to help facilitate and customize the specific needs of Jason and his team at Legacy Effects. “What really attracted me even more to working with Carbon3D were the questions they asked about me and my work flow-they really cared about solving our problems,” according to Lopes. “It was a breath of fresh air.”

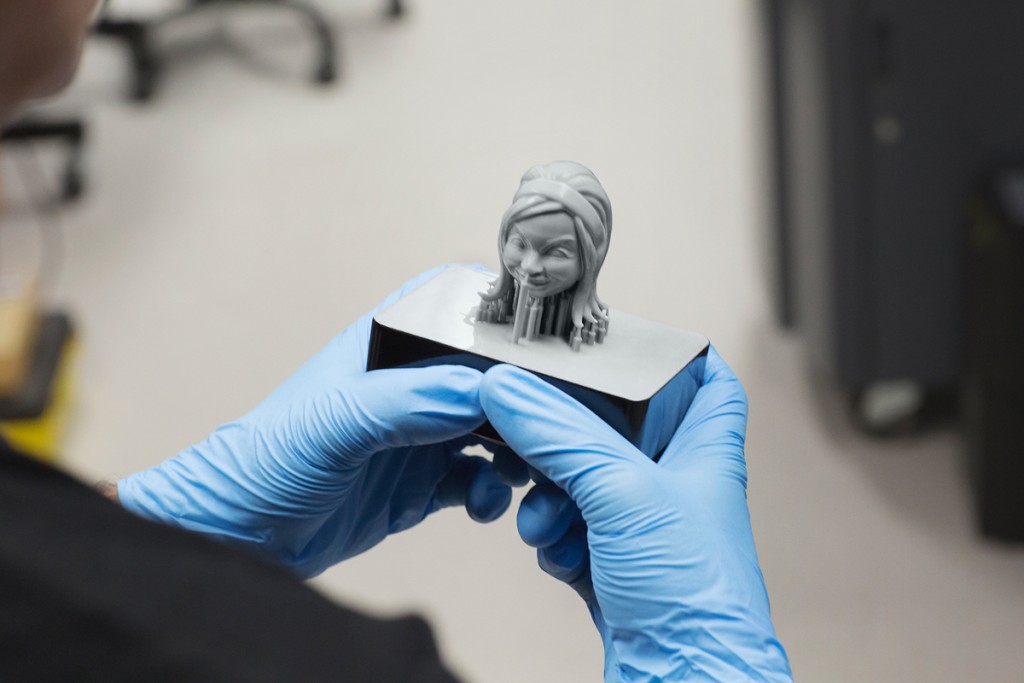

Legacy Effects put the Carbon 3D printer to work recently for a Progressive Insurance commercial. Facing a tough deadline which required the delivery of multiple parts with tricky geometries, CLIP was put to the test.

Jason elaborated about using the Carbon3D prototype: “I had the opportunity to use parts built with CLIP technology. Some parts were smaller than a pea but with intricate surface detail. The first thing I noticed was the smooth quality of the grown surface matching the geometry exactly; with no grow-lines! The parts required no body-shopping. In fact, the surface had the same characteristics of metal-mold injection plastic!” He sounds impressed. Overall, thirty parts were printed and according to Legacy Effects, the time saved helped them meet their deadline with Progressive. The commercial is embedded in full below.

Legacy Effects says that using the Carbon3D prototype, they can create three or four intricate figures that are worthy of being called final prints in one day. This is a marked improvement from using conventional 3D printing methods, which would cost them days on end. Legacy Effects is now able to fill prop delivery orders in less than 24 hours, as long as they fit the build volume.

Since the Carbon3D founders took inspiration from the T-1000 in Terminator 2 rising from a liquid on the floor into the solid form of a Los Angeles policeman, it seems only fitting that the studio is using the Carbon3D prototype for Terminator Genisys effects, as well. “CLIP allows us to do what we do best: focus on art. I can let my creative hands work where they deserve to be creatively. That’s huge. I’d rather use my talent in areas where they’re off exploring rather than going back and cleaning up prototypes. You start revisiting things you always wanted to do and try. It’s really exciting!” Lopes said.

We’re still waiting to hear what Carbon3D’s exact business plan will be, in relation to the printers. We’re also still waiting to hear about its price. But, it seems, that at least one Carbon3D customer is happy and, given their highly visible status in the 3D printing and entertainment industries, that’s an important client to have made satisfied.