A team of researchers from the Korea Electrotechnology Research Institute has used 3D printing to develop high-density quantum dot pixel arrays at the nanoscale.

By embedding and solidifying liquid inks in polymer nanowires, the scientists were able to fabricate vertically freestanding pillars capable of emitting light. The printed structures are characterized by their long length and high brightness, and can be used to “achieve super-high-resolution display devices”.

Pixels and photonic devices

Display devices, like the one you’re reading on, are typically made up of a two-dimensional array of pixels. For a 1080p device, this will be 1920 across and 1080 down, giving us 2,073,600 pixels to display the information we need to display at any given time. The number of pixels stays constant across devices with identical resolutions, but the pixel density may change as the size of the display (and the size of each pixel) changes. Higher pixel densities result in higher quality images while lower pixel densities result in granier, fuzzier images.

Pixel production usually involves the selective and repeated 2D jetting of three small compound dots surrounded by a black mask. Each of the three dots corresponds to a primary color (red, green, or blue) that emits light when excited electrically. Certain pixels can be blocked using rotating polarization filters, allowing the device to display a life-like image with a wide range of RGB colors.

The brightness of each pixel – and the brightness of the screen – tends to be limited by the pixel volume. As a result, miniaturized high-resolution display devices are often too dull to be functional.

3D printed quantum dot nanoinks

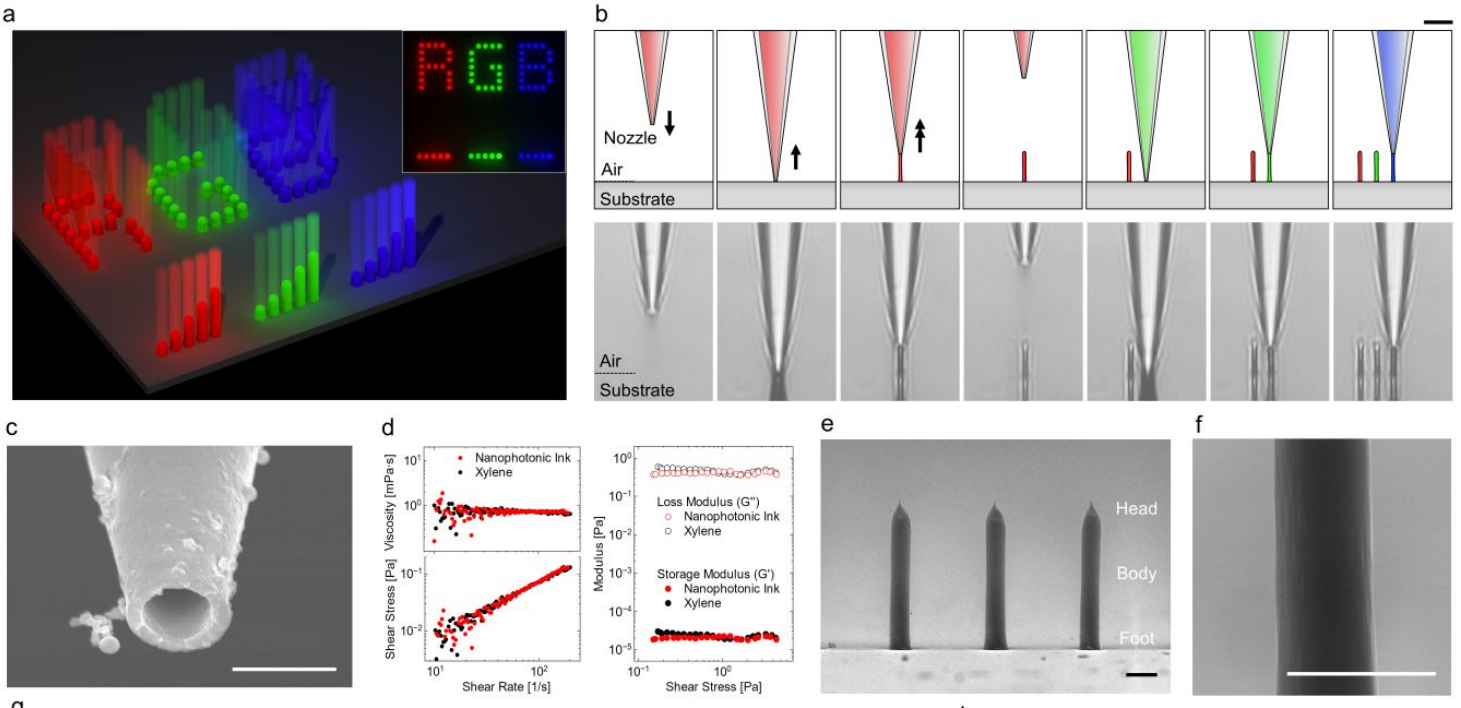

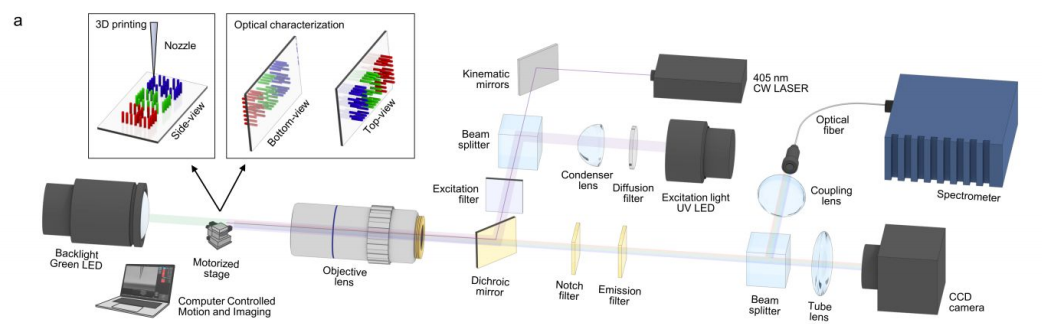

Opting for an additive three-dimensional process, the researchers first doped solvated polystyrene polymers with quantum dots that had peak emission wavelengths of 650, 540, and 480nm (corresponding to red, green, and blue). The resulting nanophotonic inks were 3D printed via direct writing onto a flat quartz plate substrate using a femtoliter-scale liquid meniscus and nanopipette. According to the researchers, quantum dots were selected due to their high-quantum efficiencies and relatively long-term stability.

Viewed from the side, the solid RGB structures look like long individual pillars but from the top or bottom, they look like standard pixels. Each one had a height of 3 microns and a width of just 0.62 microns, or 620nm.

Due to the volumetric aspect to the pixels, each structure enabled a two-fold increase in brightness when compared to a 2D counterpart, with no detrimental effect on the lateral resolution of the device. Furthermore, the scientists found that they could control the maximum brightness of the structures just by varying the pixel height, paving the way for functional, high-resolution miniature photonic devices.

Further details of the study can be found in the paper titled ‘3D-Printed Quantum Dot Nanopixels’. It is co-authored by Jongcheon Bae, Sanghyeon Lee, Jinhyuck Ahn, et al.

There are a number of different methods of achieving fluorescent, multi-colored prints, as seen in recent academic works. Researchers from Purdue University recently published a study detailing the development of trackable 3D printed microrobots that draw inspiration from natural geometries. Using two-photon polymerization, the team was able to fabricate scaled-down body structures that mimic those of beetles and butterflies, in that they express color under visible light at certain angles.

In a similar study, researchers from Illinois also drew inspiration from nature, choosing to mimic the nanoscale structures typically found in the light-bending skin of chameleons. The team developed a specialized ink containing branched polymers with two bonded, chemically distinct segments. The material is dissolved into a solution that bonds the polymer chains just before 3D printing, resulting in a variety of physical properties, such as vibrant colors, post-printing.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the nanopixel printing process. Image via KERI.