Researchers from Germany’s Kiel University (CAU) have developed low-cost 3D printed dome-shaped systems that optimize lighting for wildlife photography.

The modular illumination devices offer a cheaper, less complex alternative to existing lighting setups, while remaining capable of supporting scientific micro and macrophotography. Having made the STL files publicly available, the Kiel team’s system is also designed to be customized, allowing it to be tailored to the specimen being photographed.

The importance of photography lighting domes

Despite the increasing adoption of modern technologies such as micro-computed tomography (µCT), photography remains the optimal method of imaging biological objects. Taxonomy and morphology studies still rely on high-resolution photos of species’ in their habitat, as do natural history museums, which are increasingly turning to digitization.

High-quality images are particularly important in academic photography, as resolution is critical to capturing key features, diagnostic characters, and a detailed habitus view. In order to achieve the level of detail required for such biological studies, proper illumination is vital. A high level of diffused light is needed to photograph microscopic structures in great detail, particularly when using higher zoom magnifications.

By contrast, bad lighting can lead to unintentional overexposure of any nearby macrostructures. So-called ‘hard lighting’ can also cause glare and flaring to negatively impact upon the image’s final quality, and distort the features of photographed objects. Previous research carried out at the University of California Riverside revealed that hemispherical domes are highly-effective in scattering light and providing uniform illumination.

As light is emitted from the base of the dome, the photographed object is only illuminated by light scattered from the inner dome surface, leading to diffuse, soft illumination. Despite the benefits of dome-shaped systems, commercial devices can be very expensive, and if the object is too small, resolution can be suboptimal. Some animals are also considerably larger than existing dome-based systems, limiting their application in certain environments.

The Kiel University 3D printed lighting system

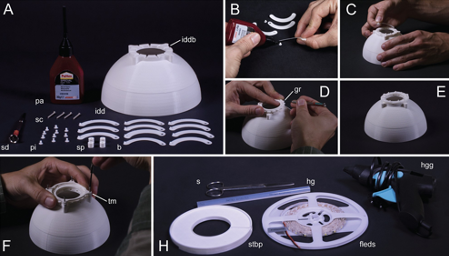

In order to overcome the size and cost restraints of commercially-available illumination systems, the researchers turned to Fused Deposition Modelling (FDM) 3D printing. The low operational expense of running FDM machines has increasingly led to their adoption in laboratory settings. Using CAD software, objects can also be produced in a customizable and scalable way, potentially allowing dome geometries to be tailor-made depending on their subject.

Utilizing 3D printing the Kiel team fabricated a modular, LED-based dome featuring a number of upgrades compared to existing devices. To maximize light yield, an optional iris diaphragm can be fitted to the system, and its ‘sliding table’ function allows the target object to be rearranged to the desires of the photographer. Additionally, simply by using 3D printing to produce the system, it features an improved quality, durability, and reproducibility in comparison to existing illumination models.

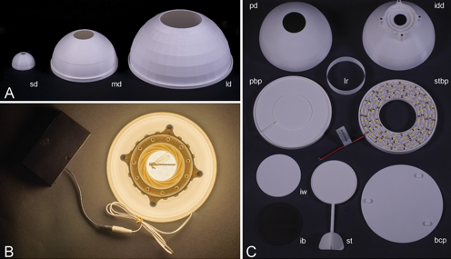

Using a Prusa i3 MK3S 3D printer, and inexpensive white PLA filament, the researchers created domes in three different sizes. Testing the team’s lighting systems involved taking photographs of taxidermied insects that were borrowed from a local zoological museum. The embalmed insects were either pinned to a glass disk or attached to a petri dish if they were an underwater specimen.

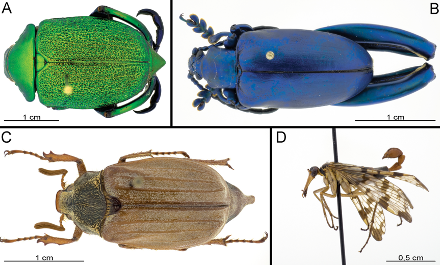

Focus-stacked images were then taken of the same specimen in each of the domes, with either warm or neutral white LED strips used for comparison. For larger objects, an extension plate and light-shielding ring were placed on top of the dome table, enabling it to be adjusted for different-sized species. Overall, the team was able to capture high-resolution images of a wide variety of different specimens, featuring insects, mollusks, vertebrates, flowers, and fossils.

The Kiel researchers concluded their LED system to be more durable and cost-effective than those produced in previous research, and that it could be capable of competing with commercial devices. By making their design as easily accessible as possible, the team also hopes that it will be adopted by students and smaller labs in the future, to help them take high-resolution images on a budget.

“Our dome represents an important improvement of scientific illumination methods, which highly increases its accessibility to the scientific community,” stated the Kiel researchers in their paper. “Hopefully it will prove to be a useful tool for many studies in the future. Students, labs, and people on a low budget, can now have the possibility to generate meaningful and professional images to finally compete with cutting edge labs.”

Lighting in the additive manufacturing industry

Although 3D printed electronics are still in their relative infancy, a number of researchers have experimented with creating devices that feature optimized lighting solutions.

New York’s Lighting Research Center (LRC), and American power management company the Eaton Corporation, have developed a fully 3D printed LED-integrated luminaire. The overall project, funded by the U.S. Department of Energy, aims to develop the applications of additive manufacturing to create Solid-State Lighting (SSL).

The LRC also worked with private equity business CARBON Group Global to form a consortium that explores the potential of 3D printing SSL products. Featuring a number of key 3D printing stakeholders, the group is working to develop a roadmap for integrating additive manufacturing into key industries.

Nautical technology firm OceanLED has used 3D printing to fabricate prototype low-energy consumption lighting systems for high-end yachts. The rig illuminates the water around the bottom of the boat, creating an “aquarium effect” as fish are attracted to the light.

The researchers’ findings are detailed in their paper titled “Illuminating nature’s beauty: modular, scalable and low-cost LED dome illumination system using 3D-printing technology,” which was published in the Advanced Functional Materials journal. The report was co-authored by Fabian Bäumler, Alexander Koehnsen, Halvor T. Tramsen, Stanislav N. Gorb, and Sebastian Büsse.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a lateral photo of the beetle Burprestidae took with lighting provided by the team’s dome. Image via the Scientific Reports journal.