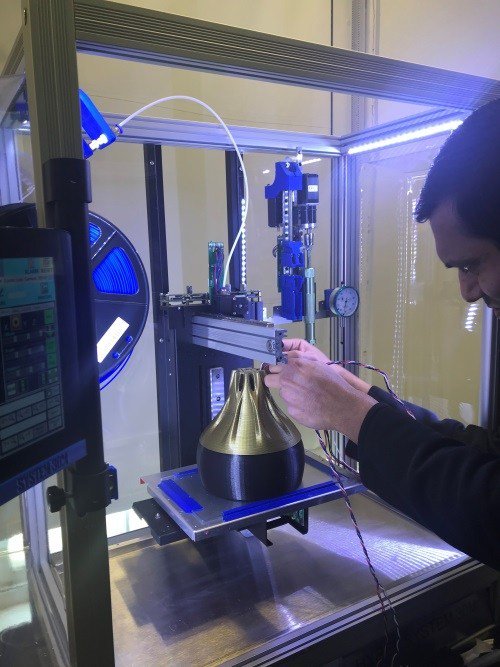

The Lighting Research Center (LRC) in Troy, New York, and American multinational power management company Eaton Corporation, have partnered to develop a fully 3D printed LED-integrated luminaire.

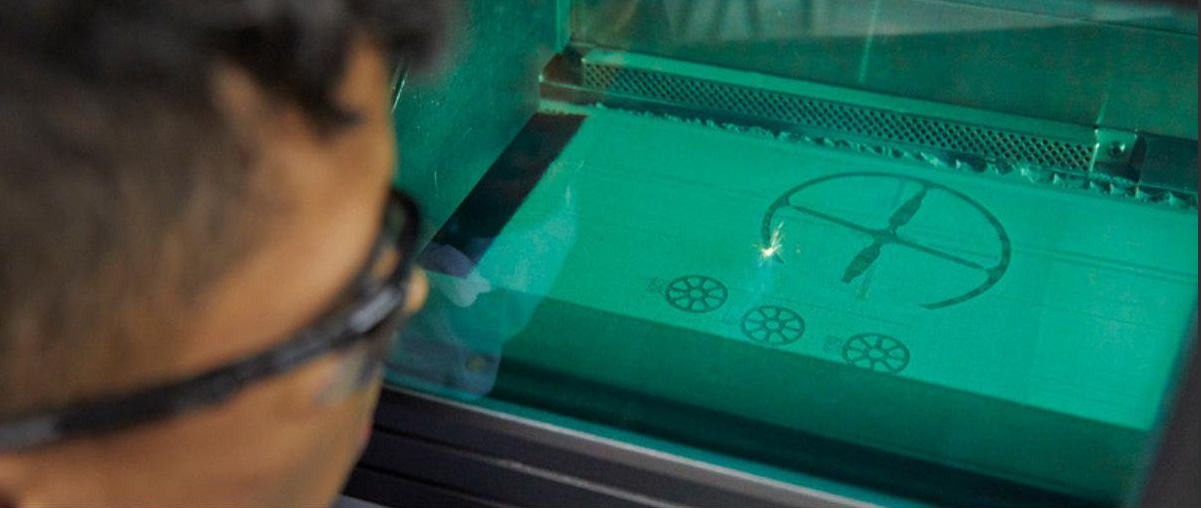

This project, funded by the United States Department of Energy, aims to overcome the barriers for the adoption of additive manufacturing technology applied to solid-state lighting (SSL).

Solid-state lighting and 3D printing

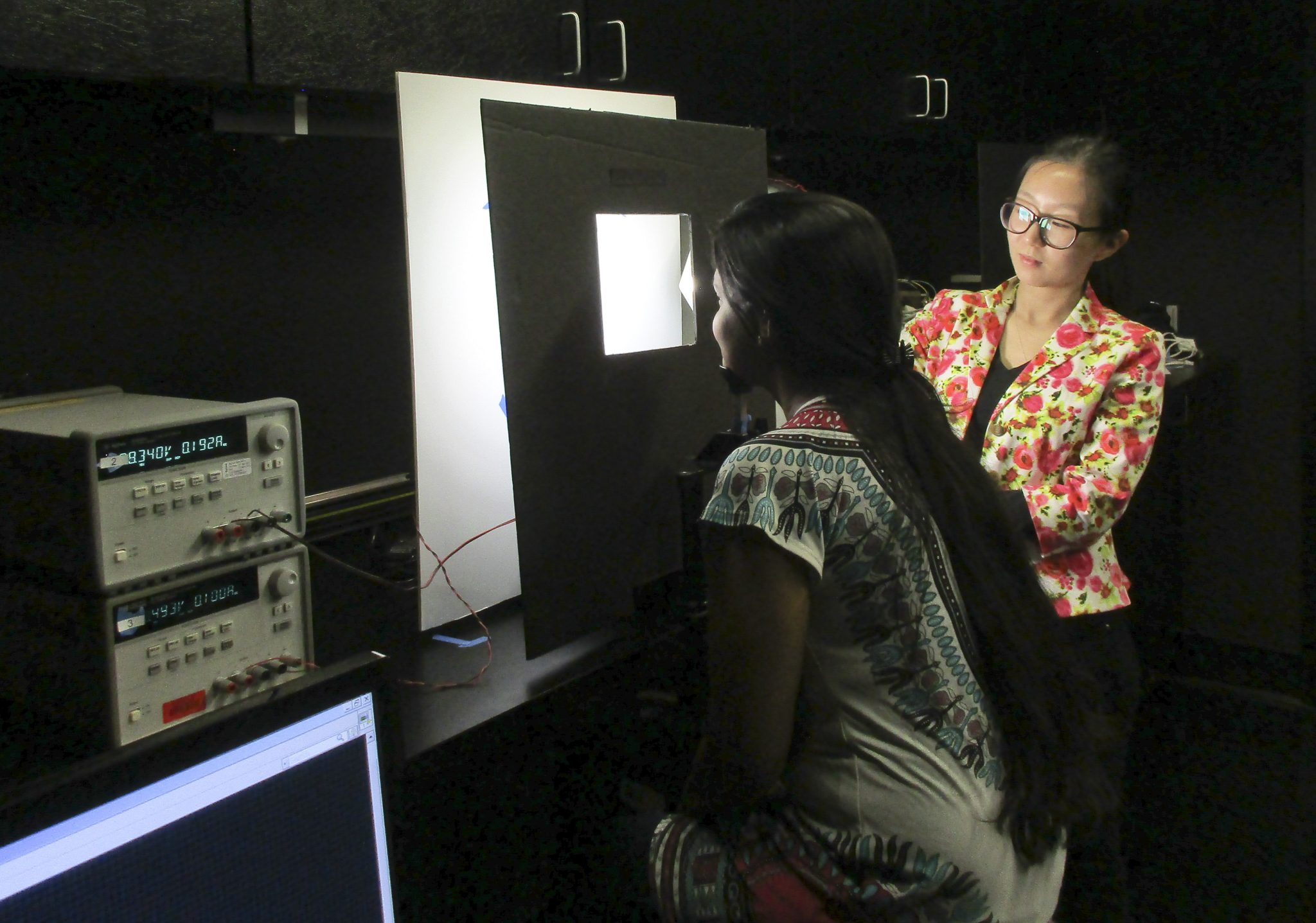

Stemming from the Rensselaer Polytechnic Institute, the LRC conducts research in light and human health, transportation lighting and safety, SSL, energy efficiency, and plant health. Earlier this year, it formed a consortium to explore the potential of 3D printing for SSL, building, and construction industries.

Over the next two years, LRC’s new partnership, which is led by Eaton Corporation, will conduct research in material science, electronics, optics, and advanced manufacturing to investigate the potential of cost-effective, 3D printed luminaire systems. As SSL, luminaire systems use organic light-emitting diodes (OLEDs), or light-emitting polymers. According to the LRC, this differs from incandescent or fluorescent lamps, which create light with filaments and gases encased in a glass bulb.

Instead, SSL consists of semiconductors that convert electricity into light, and before the 2000s, they were used only in electronic devices as indicator lamps. Thus, components of SSL systems will be fabricated using additive manufacturing methods such as mechanical and thermal management, electrical and electronic and optical and light reflector structures.

Eaton Corporation for sustainable production

Recently, Eaton Corporation recognized additive manufacturing as a valuable method for achieving Zero Waste to Landfill (ZWTL) status for a number of its sites. Its venture into SSL also encourages sustainable production. This project, in particular, is selected through the energy department’s SSL R&D Funding Opportunity program.

The company previously stated, “Around the world, our teams are actively engaged in programs that reduce our own waste and carbon dioxide emissions and optimize our use of energy, raw materials, and natural resources.”

To stay up to date with all the latest 3D printing applications news subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Looking for an opportunity in the 3D printing industry? Visit 3D Printing Jobs to commence your career in additive manufacturing.

Featured image shows the inside the Lightning Research Centre. Photo via The LRC.