Global information technology company HP has partnered with Oakley, a California-based sports brand, to create 3D printed prototypes and functional parts across Oakley’s portfolio of products.

Using Multi Jet Fusion, Oakley is reducing the product development stages of its eyewear selection as well as other athletic equipment. Nicolas Garfias, Head of Design at Oakley, explained:

“World-class athletes around the globe depend on Oakley to compete at the highest level. With HP’s breakthrough 3D printing technology, we will not only accelerate our design to production timeline, but we will also reconceptualize the way our products are made, pushing the boundaries of sports performance to new heights.”

3D printing and eyewear

Founded in 1975, Oakley, a subsidiary of leading eyewear Luxottica, began integrating 3D printing into its design methodology in 1992 to create the Eye Jacket sunglasses. According to the company, additive manufacturing transformed its development process as well as the silhouette of its sunglasses.

As of 2018, the company has been utilizing HP’s Multi Jet Fusion for rapid prototyping across multiple product lines, including sunglasses, helmets, and trophies. “Oakley has the highest of design standards, and our innovative 3D printing technology helps them deliver on that experience for millions of athletes around the world,” said Jeff Fawcett, 3D Printing Product Management at HP Inc. “Together, we are transforming the sports performance community and changing the way the world designs and manufactures consumer products.”

Rapid prototyping with HP

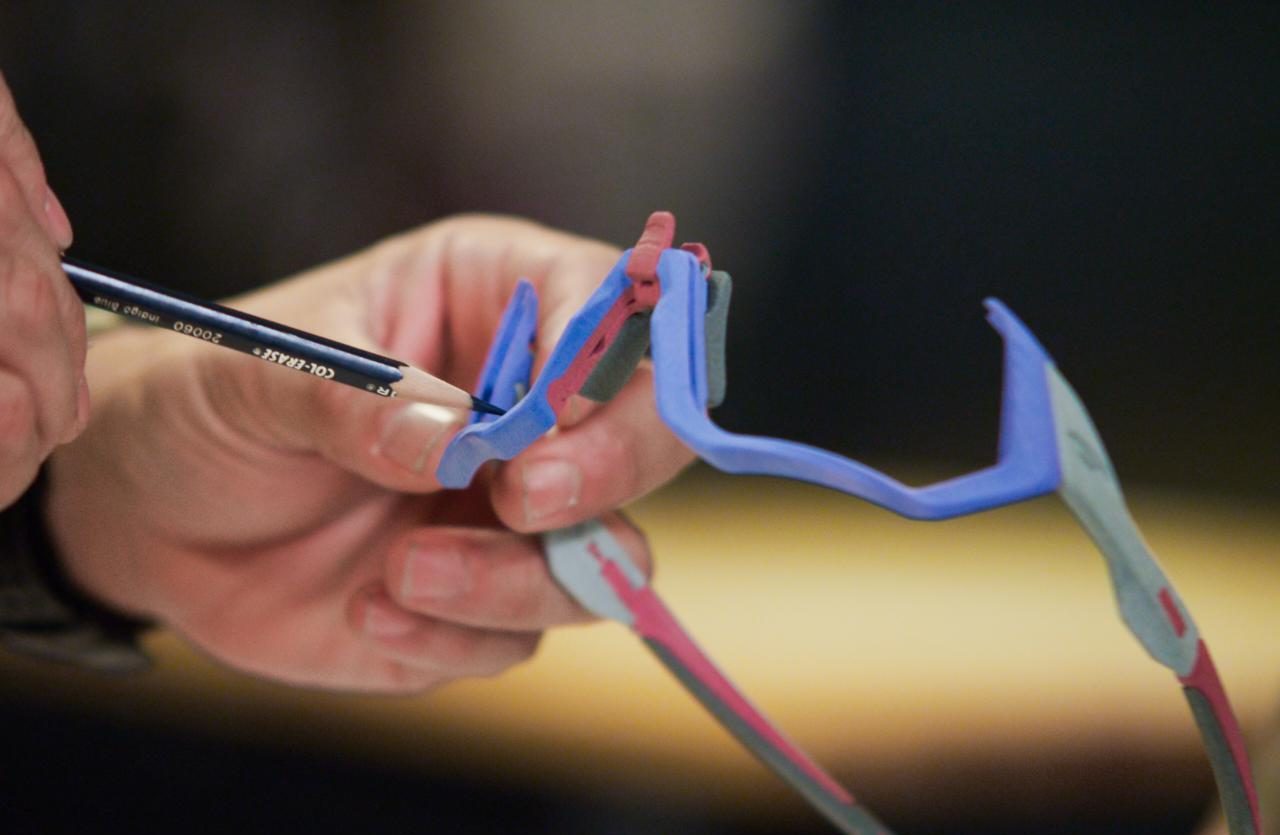

Specifically, Oakley is using the HP Jet Fusion 580 additive manufacturing system to speed up the design iteration process as designers can fabricate and test color-coordinated parts in a day. This process would usually take two to three weeks. The 580 is also capable of producing full-color functional parts while maintaining optimal mechanical properties.

This system is said to print complex components in a fraction of the time when compared to plastic FDM/FFF, SLA, and material jetting solutions. It uses HP 3D High Reusability CB PA 12, a polymer designed to be recycled for further use.

Accelerating athletic performance with additive manufacturing

Additive manufacturing has been incorporated into sports equipment to improve athletic performance. Earlier this year, Carbon, the Silicon Valley-based start-up behind Digital Light Synthesis (DLS), announced a partnership with American football equipment provider Riddell to develop customized 3D printed NFL helmet lining.

Following this, the company began collaborating with fizik, a US-based cycling equipment manufacturer, to create Adaptive, a 3D printed bike saddle. With DLS, Adaptive provides zonal cushioning and improved support and power transfer properties with personalized data from the cyclists.

More recently, in September, GuardLab, a New York-based sports technology brand, also partnered with Bauer Hockey, to launch personalized 3D printed mouthguards.

Keep up with the latest 3D printing news by subscribing to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for an opportunity in the 3D printing industry? Visit 3D Printing Jobs to commence your career in additive manufacturing.

Featured image shows 3D printed Oakley eyewear frames created using HP Multi Jet Fusion. Photo via HP.