June 2019 was an important month in 3D printing, not least because of our third annual 3D Printing Industry Awards, where our readers voted on the best of the best in additive manufacturing.

Also in the headlines was Adam Savage, who became a real-life Tony Stark with his 3D printed Iron Man suit. In June, we also answered important questions surrounding the development of 3D printing in the near future.

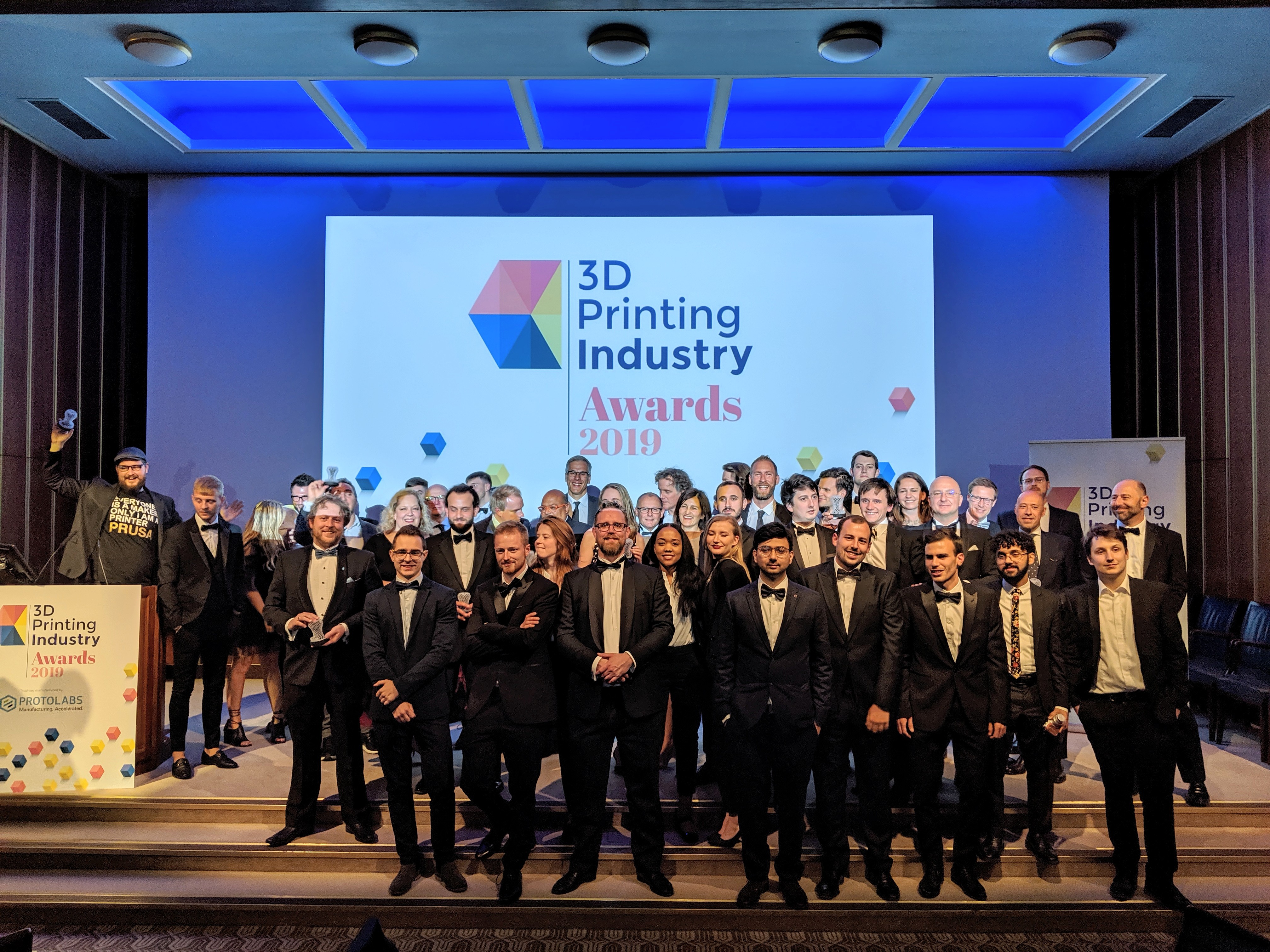

The 2019 3D Printing Industry Awards

Hosted in central London, the 2019 3D Printing Industry Awards our guests, representing over 60 companies in both desktop and industrial additive manufacturing. Welcoming guests from Protolabs, AM Ventures, RPS, Voxeljet and more, also in attendance was a royal family member, His Highness Azzan Kais Tarik Al-Said of Oman.

Winners included GE Additive for OEM of the Year (Enterprise), CRP Technology was awarded Material company of the Year, and BCN3D Technologies and the University of Girona won the Medical, Dental or Healthcare Application of the Year. 3D Printing Industry also awarded Dr. Hans Langer, founder of EOS, the Outstanding Contribution to 3D Printing award.

Sometimes you gotta 3D print before you can walk

For those of you that don’t know, Adam Savage is an American special effects designer and former co-host of popular Discovery Channel show MythBusters. In June, Savage showcased his very own 3D printed Iron Man suit, for his new TV show Savage Builds. Aired on June 14, the episode demonstrated the 3D printed titanium build, which was granted flight capabilities thanks to the well-known arm-mountable rocket thrusters from Gravity.

The suit had been in development since at least 2017 and was made alongside Colorado School of Mines, leading 3D printer OEM EOS, ceramic 3D printing specialist Lithoz, and Hollywood movie effects specialist Legacy Effects.

Other notable applications of 3D printing in June came from IKEA, which teamed up with UNYQ, a San Francisco-based assistive device developer, to 3D print a number of products for the gaming community using Carbon technology. Included in the range is a biometric wrist support which maintains the correct height of the gamers’ wrist to the keyboard, reducing strain on their tendons.

Some of the most popular articles in June asked important questions about 3D printing. Such questions included: When is 3D printing more economical than injection molding? The answer is in mass customization, as 3D printing enables manufacturers to produce multiple entirely unique, end-use products and functional prototypes within a single build volume. We also explored whether plasma is the missing link in assembling 3D printed parts.

3D printing runs the footwear market

3D printing technology has made a significant impact in the footwear industry, and June saw a number of updates and new entries in the market. Boston-based sportswear company New Balance launched a new 3D printing platform enabled by Formlabs, to produce custom, lightweight shoe components, named TripleCell. Together the companies reimagined the New Balance 990 Sport and FuelCell Echo shoes. Dávid Lakatos, Chief Product, Officer of Formlabs, said “3D printing is changing how companies approach manufacturing.”

“With this announcement New Balance is pioneering localized manufacturing.”

Additionally, Z-Sharp 3D Technology, a Chinese additive manufacturing start-up, invested 20 million CNY (approximately USD $3 million) into a new 3D printing facility in the city of Wuhu. The site was built to enable the production of 3D printed TPU midsoles for sports footwear. Carbon, responsible for the 3D printed midsoles in the ADIDAS 4D line, raised over $260 million in growth funding in June, leading to a new valuation north of $2.4 billion to the Silicon Valley 3D printing company.

Boom Supersonic and 3D printing

In aerospace, Boom Supersonic, a Colorado-based aerospace company, made a couple advances in relation to 3D printing. To help the development of its XB-1 prototype aircraft, the company signed two partnerships with Stratasys and Velo3D. Boom Supersonic aims to integrate 3D printed hardware into the XB-1 aircraft, prototype for the company’s vision of supersonic commercial airliner.

Additionally, Californian 3D printed rocket manufacturer and launch service provider Relativity Space was granted permission to expand facilities at NASA’s Stennis Space Center in Hancock County, Mississippi. In agreement with NASA and the Mississippi Development Authority, the company was given exclusive use of up to 220,000 square feet of space to build a robotic 3D printing factory and test facility for the Terran 1 rocket.

Rolls-Royce, the British manufacturer and distributor of power systems for aviation and automotive industries, also announced plans to 3D print aerospace parts with SLM Solutions quad-laser technology.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D Printing Industry team onstage with all winners of the 2019 3D Printing Industry Award. Photo by Vickie Licková for 3D Printing Industry.