In 1989 talented physicist Dr. Hans Langer founded German 3D printer OEM EOS GmbH. Now celebrating its 30th anniversary, EOS is a leading name in the global additive manufacturing market. With locations across America, Asia, Africa and Europe, it provides both polymer and metal 3D printers, expert consultancy services, and innovations aimed at advancing the progress of the technology.

Still a family-run business, Dr. Langer’s avant-garde vision for the potential of 3D printing back in the 1980s and his continued leadership of the EOS Group as Chairman and CEO, is to be recognised at this year’s 3D Printing Industry Awards.

Joining Dr. Adrian Bowyer, founder of the RepRap movement, and Fried Vancraen, Founder and CEO of 3D software developer and service provider Materialise, Dr. Langer will be awarded our Outstanding Contribution to 3D Printing accolade at the 2019 awards ceremony on June 6th. Ahead of the event next month, we asked Dr. Langer about his experience in the industry and the visions he has for the future of additive manufacturing.

3D printing “vital to the success of digital manufacturing”

Dr. Langer’s introduction to 3D printing came in 1985 when he joined laser system specialist General Scanning and began looking into early patents on the technology. Recognizing the potential ways 3D printing could become an accepted method within the manufacturing sector, Dr. Langer eventually left General Scanning to set up his own company with $500,000 in seed funding. “Very early on,” he comments, “I have been envisioning industrial 3D printing to become suitable for mass-customization and EOS to become the leading provider in this field.” Over the past decade he says that developments in computed processes have “opened up manufacturers to the potential of 3D printing for a fully digitized production.” He states:

“The industry is currently going through a fundamental shift where technology is at the core.”

In the last ten years, Dr. Langer says he has observed a large uptake in 3D printing, which he attributes to “the influx of data, analytics, machines, robotics” which organizations are using “to make production more efficient.”

“We’ve moved away from 3D printing being a novelty and ‘nice to have,’ to something that’s vital to the success of digital manufacturing.”

Realizing mass customization

Maintaining his vision from the very early days of EOS, Dr. Langer asserts that “3D printing has the potential to completely transform manufacturing.” In addition, he says, “it will be one of the key drivers of the digital factories of the future.” This drive is evidenced by EOS’ commitment to the NextGenAM Project which recently reached completion. Through NexGenAM, EOS and collaborators Daimler and Premium AEROTEC, have built an automated, digital factory, that conducts additive manufacturing at scale. The first part to be produced on the line so far is a replacement diesel engine bracket for Premium AEROTEC. The partners are now working to validate new parts on the line.

For the true potential of mass customization to take hold in additive manufacturing, Dr. Langer notes that it will be a joint effort between hardware, software and materials. “At the end of the day,” Dr. Langer explains, “it is not just about systems – EOS provides entire digital AM solutions to support customers in finding their way into the digital production.”

EOSCONNECT and EOSTATE program suites are just two examples of EOS’s software solutions for the 3D printing industry. With EOSCONNECT, the company has created platform that enable users to integrate their IOT-ready EOS 3D printers within existing IT infrastructure. Further, the EOSTATE suite enables operators to conduct real-time monitoring of their processes. The aim is, according to Dr. Langer, “to develop more intelligent and autonomous ways to enhance today’s engineers work.”

Further, EOS’s material development, powder handling systems, and automated post-processing are also a key part of this strategy. Dr. Langer comments, “Digital materials and related processes will drive down cost and allow for voxel-based part properties in the future.”

The future of additive manufacturing: injection molding competitive and humanitarian

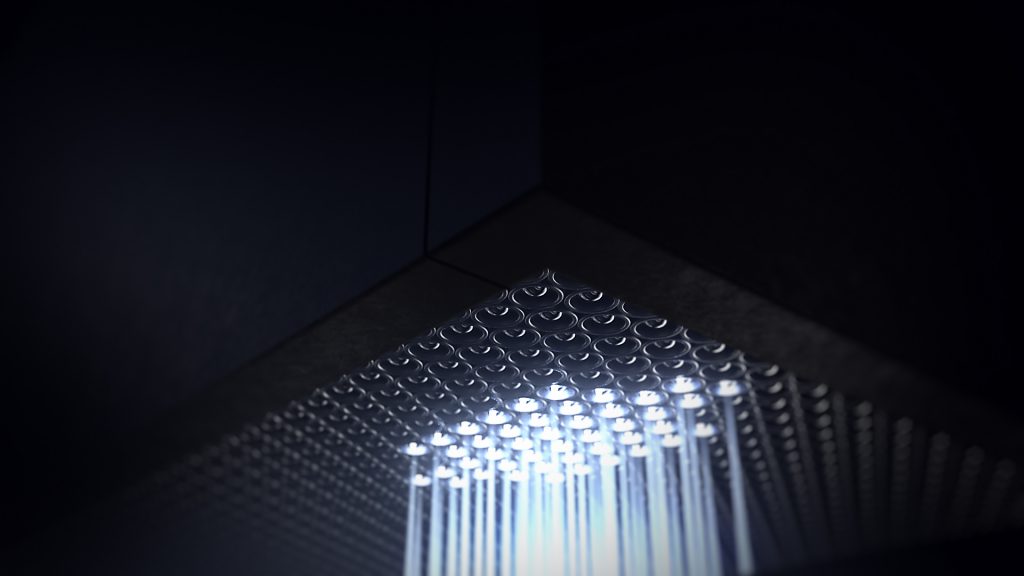

One of the ways mass customization, and 3D printing for serial production will be explored by EOS is in the development of its LaserProFusion technology. Unveiled at Formnext 2018, LaserProFusion is a forthcoming polymer 3D printing process from EOS that promises to increase “the speed of production 10 fold using one million diode lasers.”

“With the LaserProFusion technology, we are achieving a new level of productivity in polymer industrial 3D printing for serial manufacturing,” Dr. Langer comments. “It is a technology that can be an alternative to injection molding in many applications, respectively enables tool-free injection molding. This will make industrial 3D printing attractive for a completely new market in the future.”

And it’s not just “innovating for innovation’s sake” as Dr. Langer puts it. LaserProFusion is backed by a bigger picture approach at EOS, creating a complete ecosystem for customers to help them achieve specific applications across polymer and metal processes. “3D printing comes into its own when the limits of conventional manufacturing are reached,” Dr. Langer adds. “Both metal and polymers will continue to have their place and the decision will come down to specific requirements.”

“The fact that there is increasing choice available to customers will serve to realize the potential of 3D printing and mean that there are more challenges that 3D printing will be able to address.”

Looking at an even bigger picture for the future direction of EOS in general, Dr. Langer believes that additive manufacturing will play a crucial part in solving societal issues. Seeking to make the world a better place, EOS is to focus on what Dr. Langer terms a “humaneering” approach – applying science and people-centric ethics to achieve its goals.

“Besides business benefits, our technology contributes to making the world a better place to live in,” he concludes. “To address this, among others, humaneering will be a big focus for us.”

“We’re already working with many leaders globally in helping them to design and produce custom products – whether that’s in sport, healthcare or medicine – and this is something we’re likely to focus on in the future.”

Dr. Langer will be awarded the Outstanding Contribution to 3D Printing accolade at the 2019 3D Printing Industry Awards on Thursday June 6, 2019.

Contact us to book the last remaining tickets for this year’s event.

For more of the latest awards updates and other news subscribe to the daily 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.

Featured image shows Dr. Hans J. Langer founder of EOS GmbH and Chairman and CEO of the EOS Group. Photo by Tobias Hase for EOS