Technology from Limoges-based ceramics 3D printer manufacturer, 3DCERAM-SINTO, is set to dramatically increase the potency of current medical X-ray imaging technology via the addition of 3D printed detection components.

The 2001-founded ceramics expert will use its advanced ceramics 3D printing technology to aid in the completion of the European Project H2020 NEXIS – developing the next generation of medical X-ray imaging systems.

The 3DCERAM team is building the detector portion of the X-ray imaging system. Their latest system, the C900 FLEX, will be used to 3D print ceramic scintillators which exhibit luminescence when struck by ionising radiation by absorbing and converting the incoming energy.

European Project H2020 NEXIS

The NEXIS project (Next Generation X-ray Imaging System) aims to advance the functionality and image quality found in current interventional X-ray imaging systems, allowing radiologists to perform stroke diagnosis directly in the intervention suite. The state-of-the-art system will provide imaging with enhanced contrast, while maintaining high spatial resolution.

This allows medical personnel to react quicker in the operating room with a more efficient workflow. It is expected to significantly reduce diagnosis and treatment times, by up to 50% in some cases, saving lives in critical situations and reducing the costs associated with long-term interventional radiology.

Ceramics in biomedical

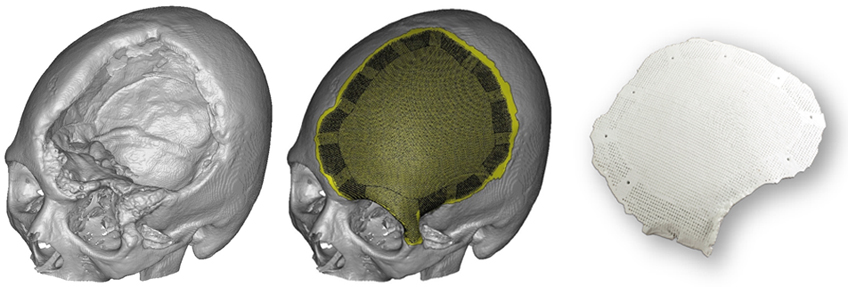

3DCERAM is an established player in the biomedical industry, having previously produced bio-ceramic cranial implants after the procedure gained approval from the EU in 2014. With almost two decades of ceramics printing experience and a plethora of ceramics printers, the French manufacturer is a worthy partner for such a high stakes project.

3DCERAM is working with independent research institute TNO and KU Leuven university. The multidisciplinary collaboration will cover the entire value chain, from R&D to medical systems through photonics and component supplies.

Richard Gaignon, CEO of 3DCERAM-SINTO, stated: “Our selection in the consortium is the recognition of the excellence in our technology and our strategy of innovation conducted for the past 17 years. This pushed us to be the world leader in 3D ceramic printing, from the design of the parts to the manufacturing stage. This partnership with Europe’s leading researchers is a great opportunity to advance science and deliver the best of 3D ceramic printing technologies to medical research at a level never before achieved.”

The benefits of AM ceramics in bioprinting and aviation

Biomedical equipment is one of many applications that have benefited from 3D printed ceramics. At the end of 2019, the 3D BioFabrication Facility on board the ISS received an upgrade in the form of 3D printed ceramic manifolds to replace the previously used printed polymers. The manifolds, which help deliver nutrients to the printed tissue cultures, provide better biocompatibility with human tissues and resulted in greater yields of biological structures.

Elsewhere, on Earth, the U.S. Air Force advanced the development of hypersonic flight vehicles with 3D printed ceramics. New ceramic thermocouple radiation shields developed by HRL were mounted onto hypersonic military aircraft due to their ability to maintain strength and form at the high temperatures typically generated at speeds of around 4,000 miles per hour.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows interventional X-ray imager. Image via Philips.