French 3D printing OEM and service bureau 3DCeram Sinto has unveiled a new ceramic 3D printer, named the C3600 Ultimate. The company will be unveiling the new system at Formnext 2019 later this month.

The new C3600 Ultimate ceramic 3D printer is designed to enable the mass production of large-scale ceramic parts, for use in advanced applications. Capable of working with a range of materials, it is suitable for manufacturing components in industries such as aerospace, defense, automotive and biomedical.

From service bureau to ceramic 3D printer manufacturer

Founded in 2001, 3DCeram has been providing ceramic 3D printing services since 2005, using its original CERAMAKER 3D printer.

In 2015, the company then opted to commercialize and market its technology through a line of SLA ceramic 3D printers based on its CERAMAKER system. This included the C900, a 3D printer with a 300mm x 300mm x 100mm build platform designed to meet the requirements of traditional technical ceramic manufacturers in the aviation, spatial and biomedical industries.

3DCeram released a hybrid multi-material iteration of the C900 in 2017, known as the C900H, capable of printing metal and ceramics together. There is also its smaller C100 system, which features a 100 mm x 100 mm x 150 mm build volume. A user friendly ceramic 3D printer, 3DCeram has marketed the C100 towards universities and R&D centers.

3DCeram announced that it had joined the Japanese industrial group Sintokogio (Sinto) in 2017, a company that sought to make greater use of 3D printing in its operations. Sinto positioned 3DCeram under its Sinto America division focusing on the foundry, surface treatment and automation industries.

3D printing larger, advanced ceramic parts

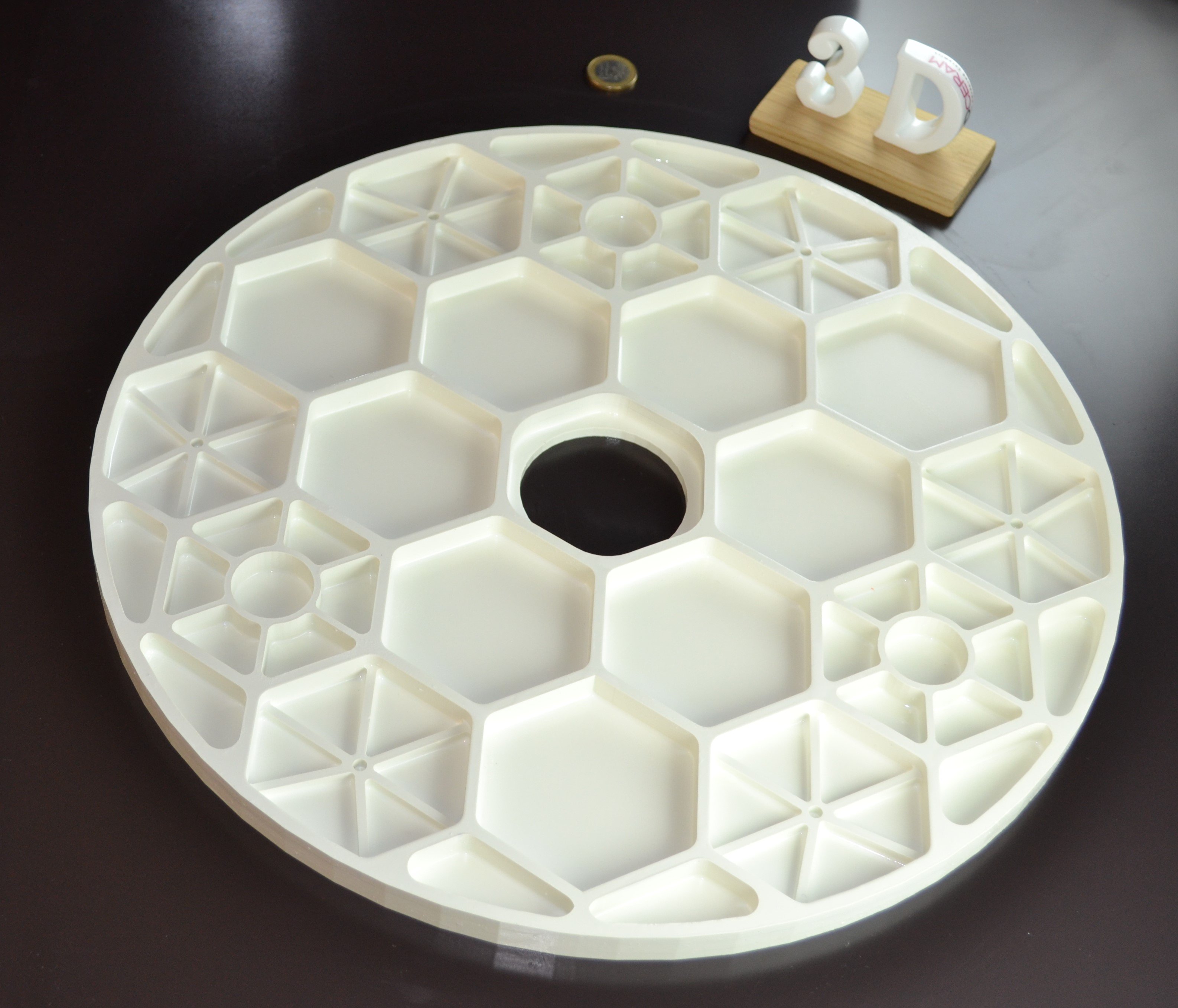

Expanding its line of CERAMAKER SLA ceramic 3D printers, the C3600 Ultimate will be the largest of 3DCeram’s systems, equipped with a build volume of 600x600x300 mm. The new 3D printer can operate with advanced ceramic materials like zirconia, which has excellent corrosion and chemical resistance, and alumina, a bioceramic commonly used in the dental industry.

The C3600 Ultimate’s build size also makes it particularly suited for producing large advanced ceramic parts, like satellite mirrors in the aerospace industry. To combat the slow speeds of SLA ceramic 3D printing, 3DCeram has equipped its new system with 4 laser sources, aiming to meet industrial print time demands.

You can find 3DCeram alongside its new C3600 Ultimate 3D printer in Hall 12.0, Stand C81 at Formnext 2019, which takes place from 19 to 22 November. Click here to discover more upcoming releases at this year’s show.

For the most comprehensive coverage of Formnext 2019 subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3DCeram C3600 Ultimate 3D printer. Photo via 3DCeram.