Researchers based in the U.S. have produced a study detailing a modified 3D printing process that provides a versatile approach to producing multiple colors from a single ink.

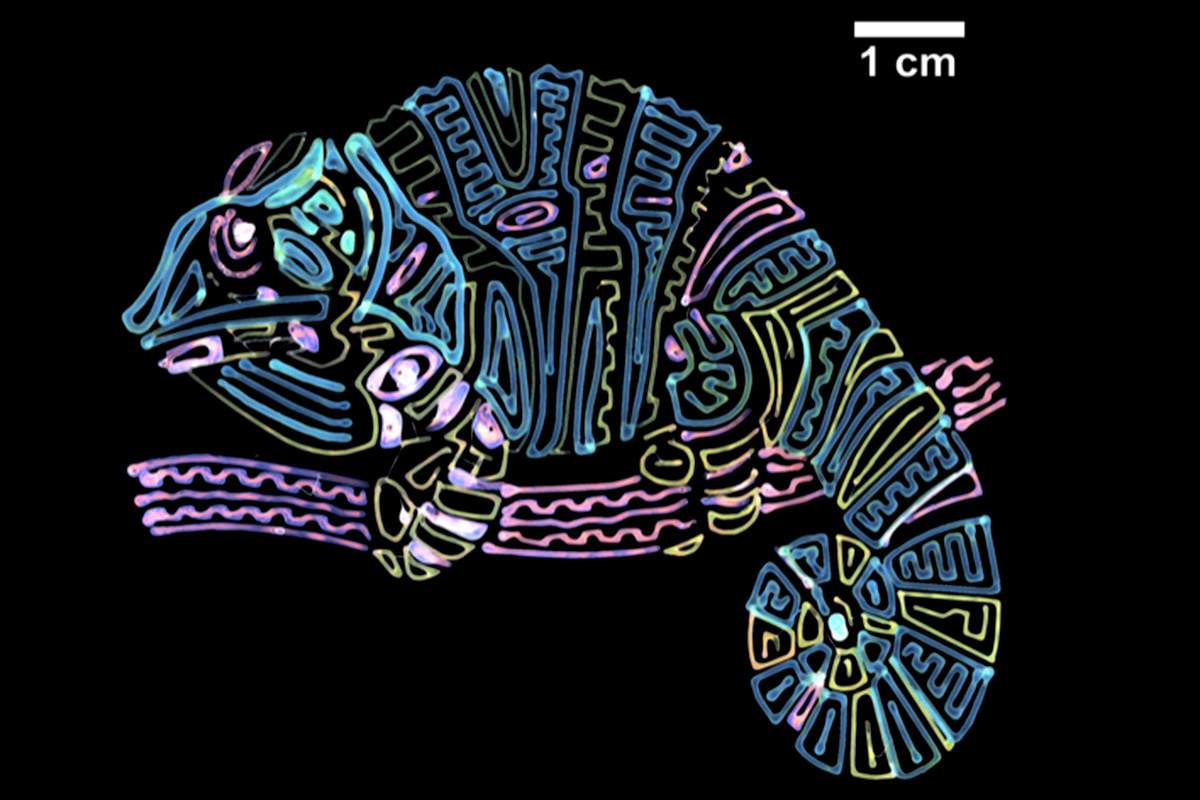

The 3D printing technique mimics structural coloration found in nature – whereby colors are produced via microscopically structured surfaces in living creatures and minerals such as chameleons, butterflies, and opals. In this instance, 3D printed materials are able to reflect color by precisely tuning them to include nanoscale structures called photonic crystals.

“It is challenging to reproduce these vibrant colors in the polymers used to produce items like environmentally friendly paints and highly selective optical filters,” explains study leader Ying Diao, a chemical and biomolecular engineering professor at the University of Illinois at Urbana-Champaign. “Precise control of polymer synthesis and processing is needed to form the incredibly thin, ordered layers that produce the structural color as we see in nature.”

Replicating structural coloration with 3D printing

An array of vibrant colors can be found in nature – from the feathers of birds to the scales of butterflies. Many of these dazzling colors are the effect of a nanoscale phenomenon known as structural coloration.

This process occurs when light rays reflect off periodically placed structures located in the wings and skins of some animals and within some minerals. They constructively interfere with each other to amplify certain wavelengths and suppress others. When the structures are well ordered and small enough – about a thousand times smaller than a human hair, explain the researchers – the result is a vivid burst of color, produced by the rays.

The research team, led by Diao, explain in their study that by carefully tuning the assembly process of uniquely structured bottlebrush-shaped polymers during 3D printing, it is possible to fabricate photonic crystals with tunable layer thicknesses that reflect the visible light spectrum from a single ink.

Contained within the ink are branched polymers with two bonded, chemically distinct segments. The material is dissolved into a solution that bonds the polymer chains just before 3D printing. After fabrication and as the solution dries, the components separate at a microscopic scale, establishing nanoscale layers that produce a variety of physical properties depending on the speed of assembly.

“The biggest challenge of the polymer synthesis is combining the precision required for the nanoscale assembly with the production of the large amounts of material necessary for the 3D printing process,” comments co-author Damien Guironnet, a professor of chemical and biomolecular engineering.

To fine-tune how fast a printing nozzle moves across a temperature-controlled surface, the research team opted to use a modified consumer 3D printer in the lab: “Having control over the speed and temperature of ink deposition allows us to control the speed of assembly and the internal layer thickness at the nanoscale, which a normal 3D printer cannot do,” adds Bijal Patel, a graduate student and lead author of the study. “That dictates how light will reflect off of them and, therefore, the color we see.”

Although currently with this method, the color spectrum achieved has been limited, the research team are working on establishing improvements by learning more about the kinetics behind how the multiple layers form in this process. Additionally, they are also looking to expand on the industrial relevance of the process, as the current method is not well suited for large-volume printing: “We are working with the Damien Guironnet, Charles Sing and Simon Rogers groups at the U. of I. to develop polymers and printing processes that are easier to control, bringing us closer to matching the vibrant colors produced by nature,” explains Diao.

“This work highlights what is achievable as researchers begin to move past focusing on 3D printing as just a way to put down a bulk material in interesting shapes,” Patel adds.

“Here, we are directly changing the physical properties of the material at the point of printing and unlocking new behavior.”

The study, “Tunable structural color of bottlebrush block copolymers through direct-write 3D printing from solution,” is published in Science Advances. Co-authors include graduate students Dylan J. Walsh and Justin Kwok, former undergraduate student Do Hoon Kim, and Guironnet, all of Illinois; and Argonne National Laboratory researcher Byeongdu Lee.

3D printing inspired by nature

A number of research in the field of 3D printing has taken inspiration from the natural world around us, usually seeking to mimic their structural forms or recreate novel effects.

For example, in 2017 scientists from the UAE published a paper detailing 3D printed lightweight cellular gyroidal shell-core structures inspired by structures found naturally in butterfly wings and lipids.

Earlier in 2020, a joint research team from the University of Cambridge and UC San Diego 3D bioprinted coral-mimicking structures capable of growing communities of microscopic algae. The study aims to provide a method of eventually reducing greenhouse gas emissions and fine-tuning the cultivation of algae for bioproducts in developing countries.

Nicole Hone, an industrial design Master’s student at the Victoria University of Wellington, New Zealand, has also designed several 4D printed interactive plants that contract or blossom, mimicking the movements of natural flowers.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Illinois researchers developed synthetic structure-based color materials – like those found in chameleon skin – for polymer inks used in 3D printing. Image via Diao Research Group.