A joint research team from the University of Cambridge and UC San Diego has 3D bioprinted coral-mimicking structures capable of growing communities of microscopic algae. The study, published in the journal Nature Communications, aims to provide a method of eventually reducing greenhouse gas emissions and fine-tuning the cultivation of algae for bioproducts in developing countries.

The symbiotic relationship between algae and coral

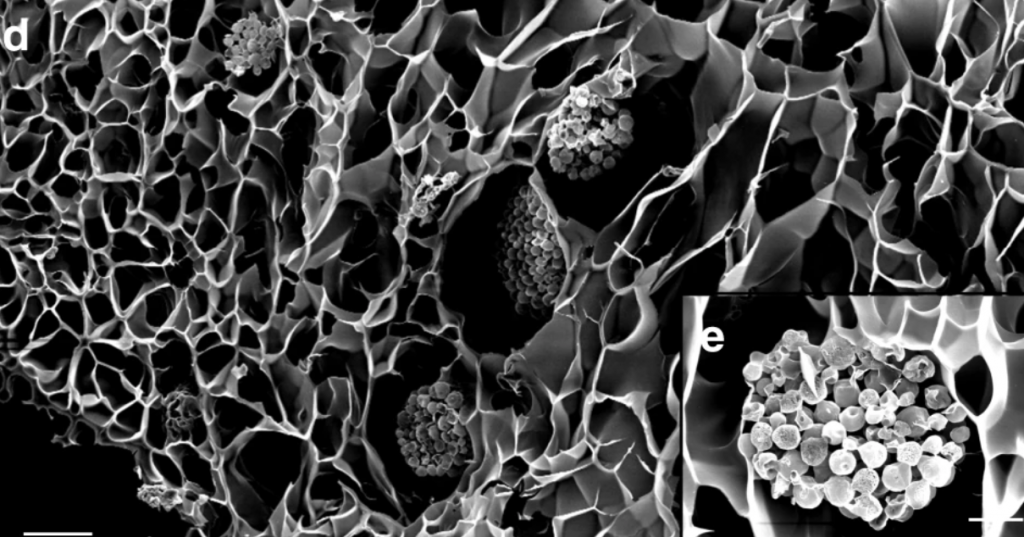

On the sea bed, coral and algae rely on each other to flourish. The coral acts as a habitat for the algae, and the algae produce glucose for the coral through photosynthesis. Through this relationship, the coral reef is maintained – a vast and diverse ecosystem found in various tropical waters around the world.

Dr. Daniel Wangpraseurt, an author of the study, explains: “Corals are highly efficient at collecting and using light. In our lab, we’re looking for methods to copy and mimic these strategies from nature for commercial applications.”

3D printing bionic coral

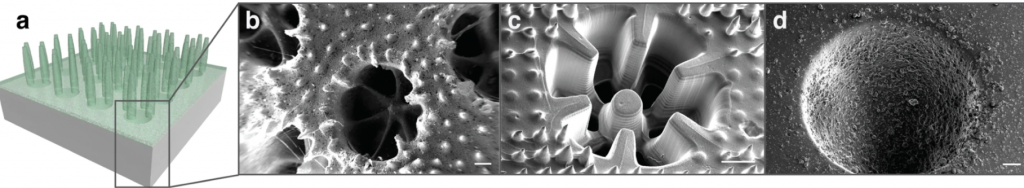

The researchers set out with the goal of mimicking the structure of coral, which is very efficient at collecting and redistributing light towards the algae inside it. To create the complex geometries found inside coral, the team first used optical coherence tomography to scan real coral and converted the scan data into 3D models.

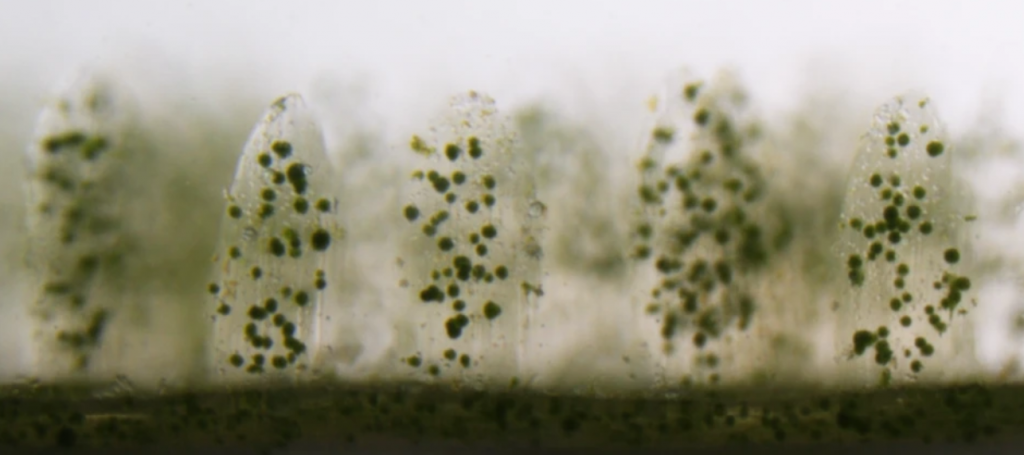

The intricate models were then 3D bioprinted using a custom setup with high resolution down to the micrometer. The bioprinter used light to fabricate coral microstructures one layer at a time, each taking just a few seconds. The artificial coral turned out to be just as efficient as the original at harvesting light and providing a host environment for the algae. Further testing of the printed coral yielded algae growth rates 100x that of standard liquid growth mediums.

Professor Shaochen Chen, a co-author from UC San Diego, explains: “This is critical for replicating structures with live cells. Most of these cells will die if we were to use traditional extrusion-based or inkjet processes because these methods take hours. It would be like keeping a fish out of the water; the cells that we work with won’t survive if kept too long out of their culture media. Our process is high throughput and offers really fast printing speeds, so it’s compatible with human cells, animal cells, and even algae cells in this case.”

Dr. Silvia Vignolini, a co-author from Cambridge University, went on to explain that the team developed the artificial coral tissue and skeleton from a combination of polymer gels and hydrogels. The gels were doped with cellulose nanomaterials – an abundant biopolymer – to mimic the optical properties of real coral.

The team hopes that its 3D bioprinted coral can be used as a model of coral-algal symbiosis, which would help them understand the deterioration of the Great Barrier Reef. They have also set up a company by the name of mantaz, which is focused on cultivating and providing algae bioproducts to developing countries.

Further details and findings of the study can be found in the paper titled ‘Bionic 3D printed corals’. It is co-authored by Daniel Wangpraseurt, Shangting You, Farooq Azam, Gianni Jacucci, Olga Gaidarenko, Mark Hildebrand, Michael Kühl, Alison Smith, Matthew Davey, Alyssa Smith, Dimitri Deheyn, Shaochen Chen, and Silvia Vignolini.

3D bioprinting is not limited to below-sea level structures. Launched last year, the 3D BioFabrication Facility on-board the ISS is being used to 3D print soft tissues in the microgravity of space, where they will not collapse under their own weight. Also operating on the ISS, Russian bio-technical research laboratory, 3D Bioprinting Solutions, has 3D bioprinted bone tissue. The team is working towards creating bone implants for astronaut transplantation during long-term interplanetary expeditions.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D bioprinted coral structure with algae. Photo via University of Cambridge.