Scientists from the UAE have published a paper detailing a one-step process of 3D printing of lightweight cellular gyroidal shell-core structures using a composite of two different materials.

In the paper entitled “Nature-Inspired Lightweight Cellular Co-Continuous Composites with Architected Periodic Gyroidal Structures,” the scientists showed that these structures produce a configuration that is tougher than equivalent structures made out of a single material.

They also demonstrated a relationship between the structural composition of the cellular composite gyroidal structures and its mechanical properties and showed that the spatial composition of the structures could be controlled and varied to produce a range of physical properties suited to a number of different engineering applications.

The significance of gyroidal structures

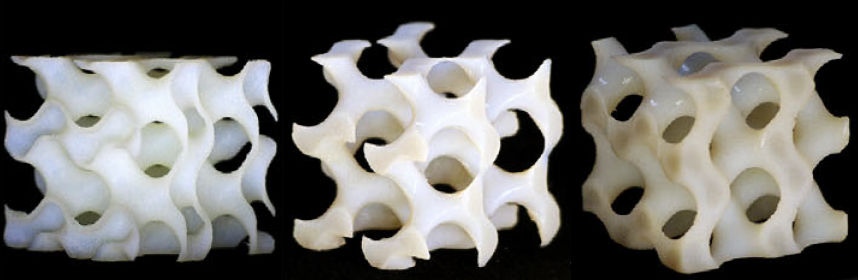

Gyroids are “triply periodic minimal surfaces” (TPMS) that are non-self-intersecting, infinitely connected, contain no straight lines and have a mean curvature of zero at each point on their surface. They are inspired by structures found naturally in butterfly wings and lipids.

Because of their minimal surface qualities, and because they can be approximated by a short mathematical equation (sin xcos y + sin ycos z + sin zcos = c, where x,y and z are coordinates and c represents the ratio of the volume of solid to the volume of void), gyroids have been a popular configuration for 3D printing test samples of graphene and ceramic for scientific investigation.

Lightweight composite gyroidal structures, which have a hard outer shell and soft inner core, like bones or wood, are suited to this study because both constituent materials are co-continuous and interconnected enhancing strength, mechanical and electrical properties. Removing one material would still leave a self-supporting structure behind.

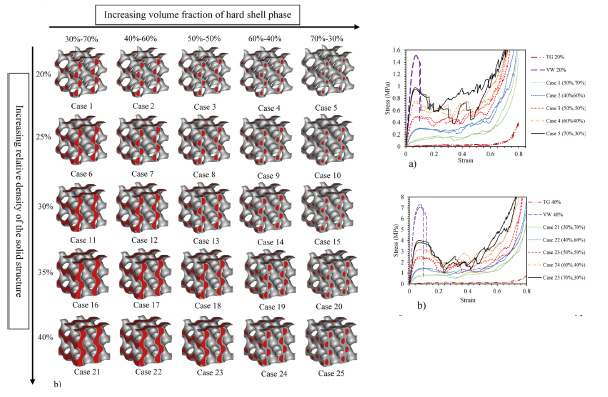

In this study, the paper’s authors claim that the controlled changes in the architecture and the constituent materials of the structures can control the structures’ physical properties. One such change can be accomplished by altering the constant c in the approximal equation, changing the volume fraction (VF) of each constituent material, and, in effect, the relative density (RD) of the entire composite structure.

Furthermore, they claim that full control over the topology of these composite gyroidal structures means an increased chance of engineering the material toward the required properties for specific end-uses, such as sandwich panels, mechanical energy absorbers, catalysts, and body implants.

3D printing the gyroids and testing toughness

The gyroidal composite structures were designed using CAD software and exported as STL files to a Stratasys Connex3 Objet 260 multi-material 3D printer. The hard outer shell was 3D printed with Stratasys VeroWhite and the soft inner core was simultaneously manufactured using Stratasys TangoGray. Samples were 90mm cubed in volume.

To test the hypothesis that the 3D printed gyroidal composite structures are stronger than the individual materials alone, samples of 100% Veroclear and 100% TangoGray were respectively tested with an Instron compression machine.

The 100% VeroClear “catastrophically failed” at both 20% and 40% RD after taking on around 1.5 and 7.5 MPa of stress at 10% strain. The 100% TangoGray was very weak and unable to even absorb half the amount of energy of the VeroClear.

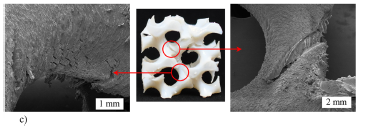

However, the gyroidal composite structures, under the same experimental conditions, display linear elastic behavior until the maximum strength is reached. After this, the Veroclear starts cracking and the TangoGray core absorbs the energy released, and densification (squashing) only begins at 60% strain.

Furthermore, a tested sample, with 35% RD, 30% VeroClear and 70% TangoGray reached 70% strain before complete destruction. It maintained more than 90% of the initial shape configuration according to inspection on a scanning electron microscope.

Testing the different microstructure configurations

To test the hypothesis that controlling the spatial composition (specifically the RD) of the cellular composite affects the physical properties of the structure, 25 test cases with varying RD and outer shell to inner core values were strain tested and the results recorded.

Manufacturing samples with varying RD values can be realised by changing the value of the constant c in the approximal equation. This increases or reduced the amount of space in a structure, and enables functional grading of the material optimized for different end-uses.

Through testing, it was shown that progressively increasing the amount of VeroClear material increased the overall mechanical properties of the sample, including Young’s modulus, yield strength, maximum strength, plateau strength, and toughness.

The toughness values of the 100% VeroWhite and 100% TangoGray were recorded alongside the composites. It was noted that the co-continuous cellular composite structures reach values of toughness that were not realized by any of the constituent materials, nor by natural materials.

With their hypotheses tested and proven, the authors now suggest more research with a wider array of combinations and materials for composite gyroidal structures, ahead of the application to specialist end-uses.

The paper was co-authored by Oraib Al-Ketan, Ahmad Soliman and Ayesha M. AlQubaisi from the Masdar Institute of Science and Technology, along with Rashid K. Abu Al-Rub from the Khalifa University of Science and Technology. It can be read here in Advanced Engineering Materials journal.

Nominations for the second annual 3D Printing Industry Awards are now open. Make your selections now.

For more information on materials and structural research, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows Dr Rashid Abu Al-Rub from Khalifa University with a gyroid structure. Photo by Christoper Pike/The National.