A team of researchers from Hanyang University, Seoul have 3D printed plastic scintillators capable of detecting gamma radiation in a highly efficient manner. The DLP printed parts were tested against a commercially available scintillator, BC408, and the team found that their creation showed a similar decay time and intrinsic detection efficiency. The researchers would now like to develop the research further and formulate a new resin recipe, one that creates parts with high density and an even higher detection efficiency in the presence of gamma radiation.

Plastic scintillators

A scintillator is quite simply an instrument for detecting and measuring ionizing radiation. It relies on the excitation effect of incident radiation on a scintillating material, whereby the material gives off visible light in the presence of ionizing rays. The resultant pulses of light can be precisely measured to give an indication of the amount of radiation in the vicinity.

When working with materials that have a lower detection efficiency, the go-to solution is to just use a larger surface area as this can make up for the lost luminescence. After a certain point, this does become cumbersome and impractical however, so it’s about finding a middle ground.

Researchers in the past have actually employed 3D printing when manufacturing plastic scintillators for radiation detection purposes. Unfortunately, these scintillators rarely match the performance of commercially available ones, with efficiencies in the region of about 70% when compared side by side. Despite this, the design freedom, multi-material capabilities, time savings, and low costs continue to make AM worthy of research.

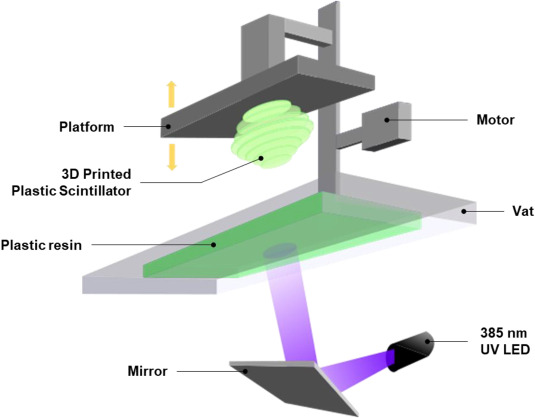

DLP for radiation detection

The team started off by formulating the special recipe for the scintillating photopolymer resin. They based the material on an acrylic monomer with naphthalene as the solvent. The scintillators themselves were printed on an ASIGA PICO2 UV DLP 3D printer. Once the samples were prepped, they had to be tested for their decay time and efficiency and compared with a commercially available scintillator – BC408.

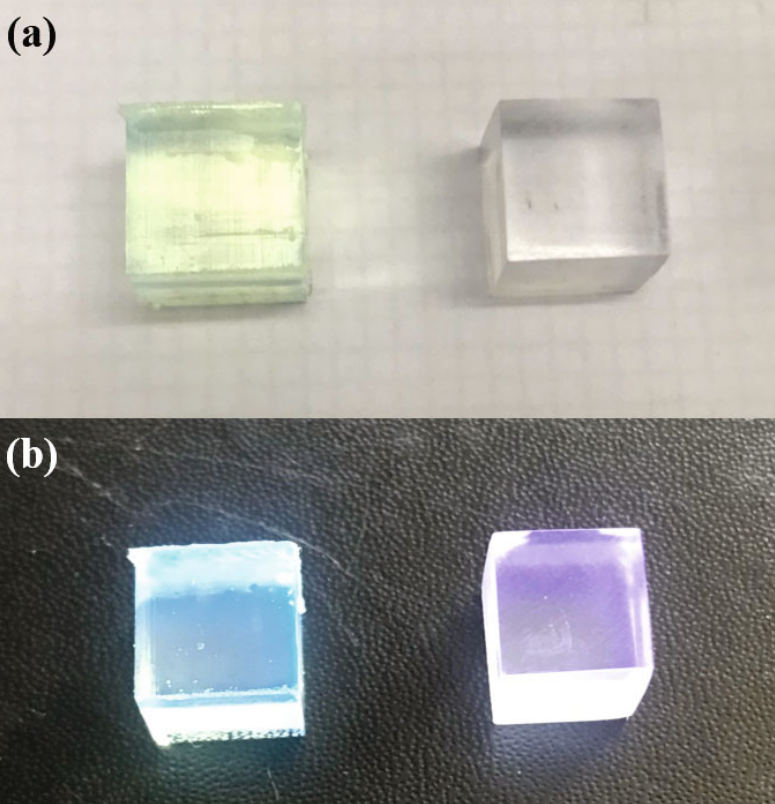

Both scintillators were exposed to a Caesium-137 source for a controlled amount of time, resulting in an incident gamma ray of 662keV. The 3D printed parts displayed an average decay time of 15.6 nanoseconds, which is the time between initial excitation and photon emission. They also had an intrinsic detection efficiency of 6.81%, which is the probability that any given gamma ray will react with the material and be detected.

Although the measured values may sound low, both of them were very closely aligned with the industry standard BC408 scintillator. The results led the researchers to conclude that their formulated resin and print parameters could be reliably used for fast timing detection purposes and in environments with high count rates – all wrapped up in a cost-effective and customizable package.

Further details of the study can be found in the paper titled ‘Performance of 3D printed plastic scintillators for gamma-ray detection’. It is co-authored by Dong-geon Kim, Sangmin Lee, Junesic Park, Jaebum Son, Tae Hoon Kim, Yong Hyun Kim, Kihong Pak, and Yong Kyun Kim.

The additive manufacturing of sensors and detectors has really started to gain some traction in the academic community. Recently, a team of researchers from the University of Washington and Sandia National Laboratories 3D printed a working carbon monoxide detector. The scientists decorated a reduced graphene oxide (rGO) sensor medium with a printed tin dioxide (SnO2) semiconductor catalyst, producing a detector that functioned at room temperature with a fast response time.

Elsewhere, in China, researchers 3D printed a flexible motion sensor using consumer-grade DLP technology. The wearable sensor was based on a tough and conductive polymer hydrogel with an impressive set of mechanical and electro-conductive properties.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

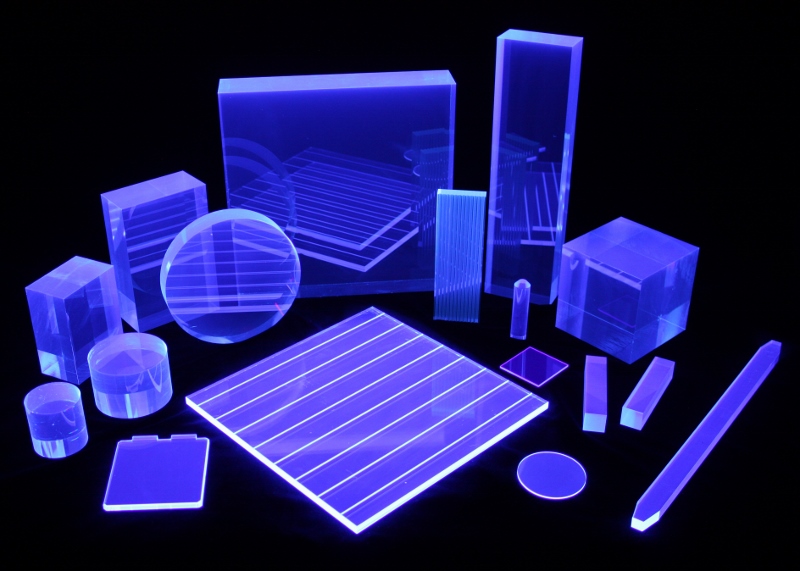

Featured image shows plastic scintillators glowing when irradiated. Photo via Eljen Technology.