A team of materials scientists from Guangdong University of Technology have formulated a high-strength vegetable oil-based photopolymer resin for SLA 3D printing. By combining soybean oil with urethane epoxy and acrylates, the researchers managed to fabricate resin parts with desirable mechanical properties without sacrificing biodegradability. Due to its biological base material, the hybrid resin is also renewable in that it can be used in a circular economy – an ever more important consideration given the current state of global resources.

Bio-resins and reusability

In recent years, we have seen the rapid emergence of environmentally-friendly manufacturing materials. Within 3D printing, this includes resins that can be recycled, renewed, and repurposed to keep them out of landfill. Bio-resins are usually made from cellulose-derived polymers, acrylate-modified polymers, and vegetable oil-based acrylates.

The vegetable oil resins, in particular, tend to be prepared via mechanical blending which often loosens the inter-penetrating networks and results in a loss of mechanical properties. Attempts to form homogeneous networks and preserve mechanical properties have been made by incorporating acrylate-modified vegetable oils but with limited success. As a result, the list of applications of 3D printable bio-based resins is a fairly short one.

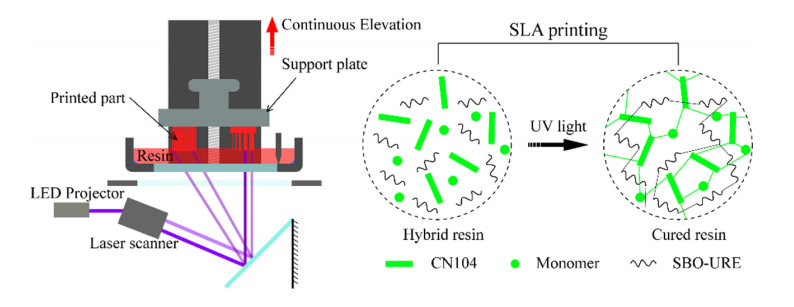

Soybean oil for SLA

The team started off by epoxidizing their original urethane-modified soybean oil and combining it with acrylates, forming the dual-curing hybrid resin for the study. Dual-curing systems are known to have a high curing rate and are used to overcome the limitations of single-curing materials. The first curing reaction forms the solid physical layer of the part while the second reaction boosts its mechanical properties, acting as a sort of reinforcement reaction in a way. The resultant part benefits from improvements in performance, with a greater strength profile as well as higher toughness.

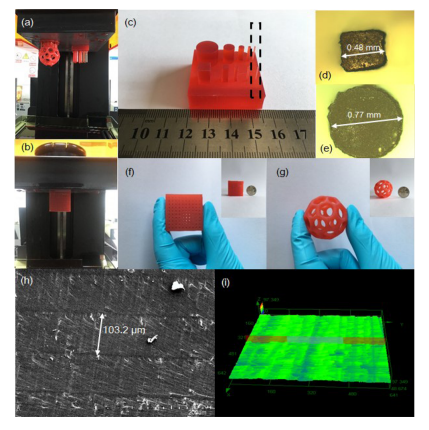

To test the promising formulae, the researchers put the printed resin parts through a series of mechanical tests. Interestingly, they found that the addition of excess soybean-urethane into the epoxy acrylate resulted in an increase in mechanical strength without sacrificing elongation. Across the board, they saw that their hybrid resins were able to produce high-resolution prototypes with “complex microarchitectures and excellent surface finishes”. The results of the study led the scientists to conclude their ‘winning combination’ had great potential as a renewable 3D printing material.

Further details of the study can be found in the paper titled ‘3D Printing of a Dual-Curing Resin with Cationic Curable Vegetable Oil’. It is co-authored by Yanyan Cui, Junlai Yang, Dehua Lei, and Jiahui Su.

In recent years, resin research has yielded a number of seemingly fantastical material properties. Recently, a team of researchers from Madrid 3D printed a set of self-sensing composite parts using DLP 3D printing technology. By reinforcing a commercially available photopolymer resin with carbon nanotubes, the researchers were able to functionalize it with electrical conductivity, making it useful for structural health monitoring.

Elsewhere, in San Diego, researchers have developed an expandable foaming resin for use with SLA 3D printers. When exposed to heat post-curing, the resin expands by up to 4000% (40x), allowing for the production of parts larger than the build volume of the printer used to fabricate them.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows parts 3D printed with the soybean oil resin. Image via Guangdong University of Technology.