Researchers from the Shanghai Institute of Technology have 3D printed a tough and conductive polymer hydrogel (CPH) based on a double network to produce flexible wearable motion sensors. The sensors were tested and evaluated for their mechanical and electroconductive properties. The team found that the CPH in the study would make an excellent 3D printing material for a number of applications, including soft robotics and even wound dressings.

Conductive hydrogels

Hydrogels have been used extensively in research projects ranging from regenerative medicine to soft robotics and 4D printing. Unfortunately, the often low mechanical strength of traditional hydrogels limits their potential to low-stress applications. With recent advances in materials science, however, highly stretchable hydrogels, conductive hydrogels, 3D printable hydrogels, and self-healing hydrogels have been formulated.

Electrically conductive hydrogels in particular, with their strong adhesion, high porosity, sensitive swelling, and biocompatibility are cited as having attracted great interest. They are capable of transforming physical external stimuli into electrical signals which can be recorded. In light of the plethora of attractive properties, the researchers saw a number of potential innovative applications of conductive hydrogels and set out to 3D print their own flexible wearable motion sensors.

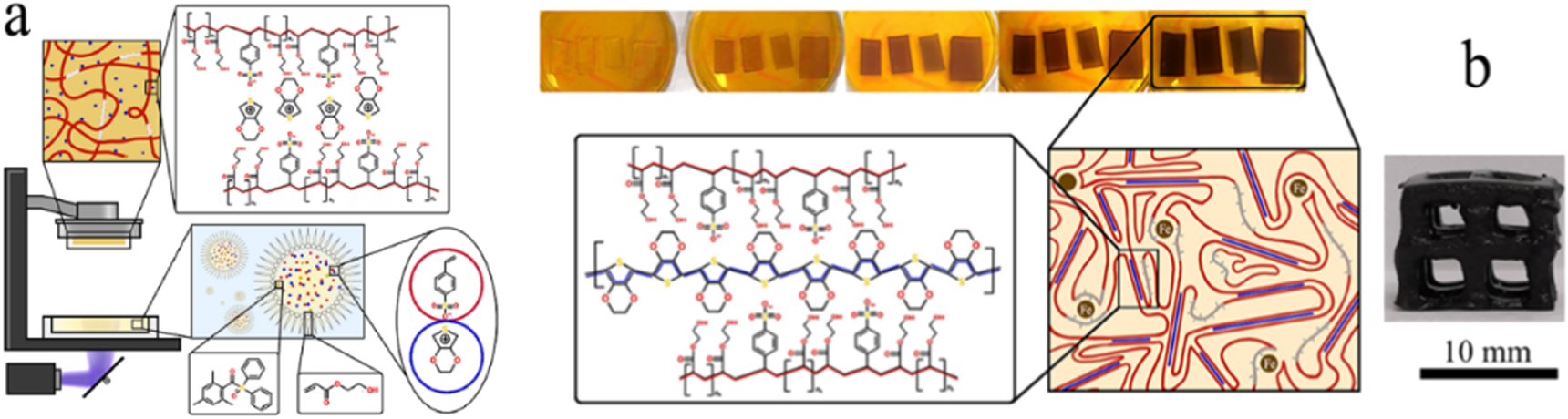

3D printing the flexible motion sensors

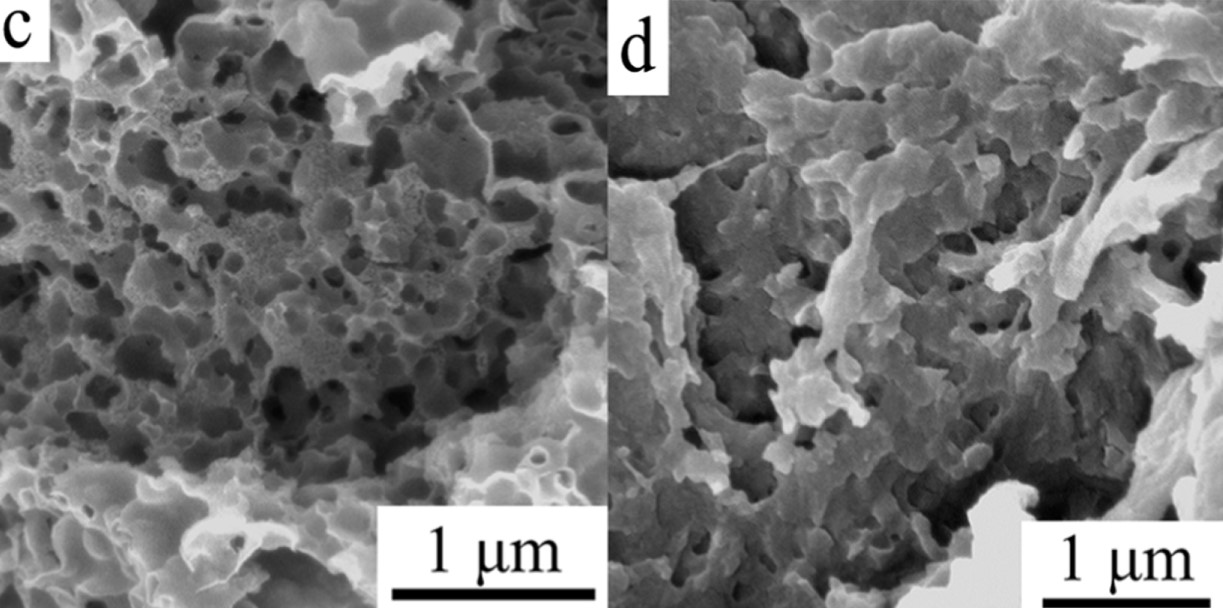

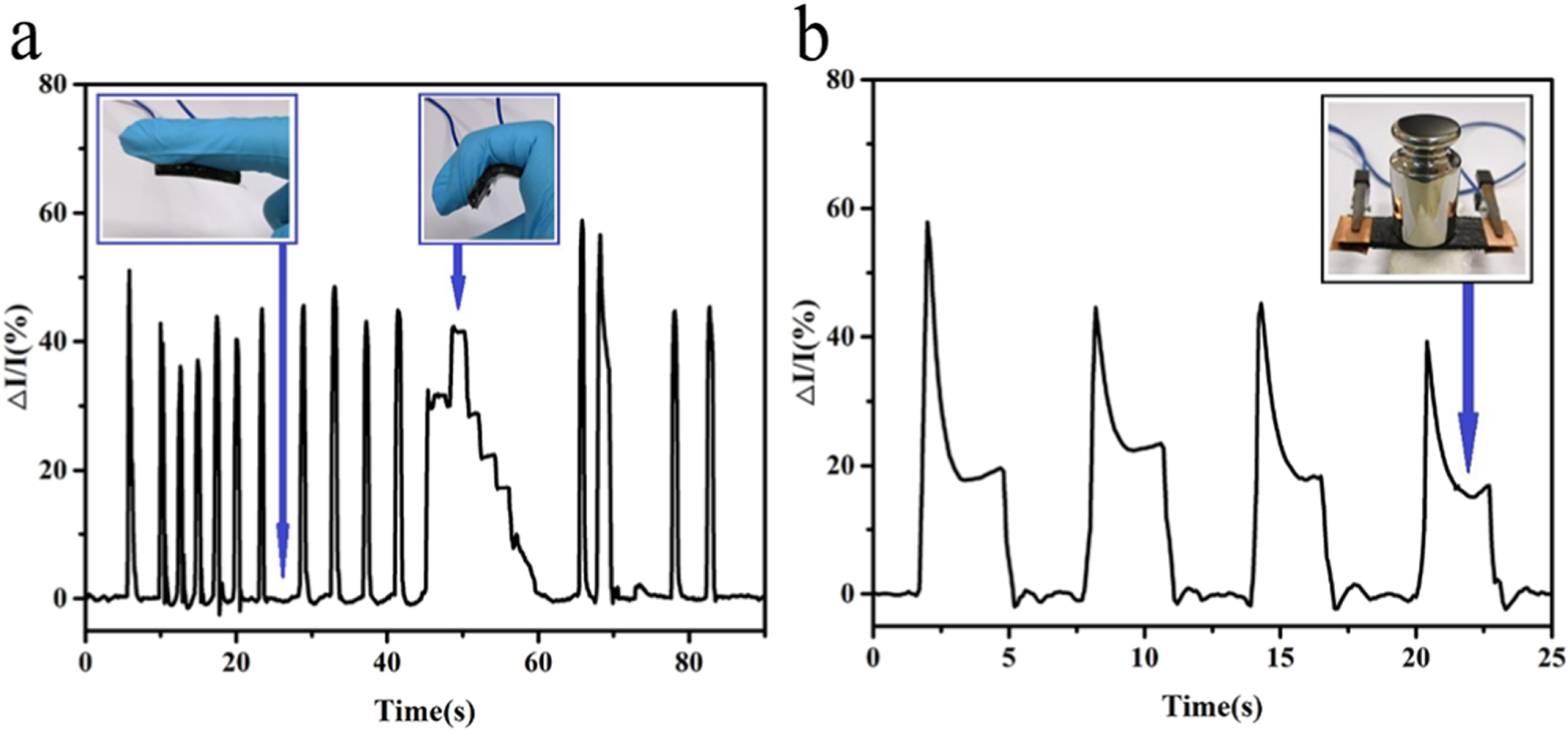

The first stage of the study involved synthesising the hydrogel. The team copolymerized HEA with SSS using a DLP 3D printer and added EDOT into the network. The result was a 3D printed PHEA-PSS/PEDOT hydrogel motion sensor. The team tested the newly formulated hydrogel and found that it displayed some surprisingly desirable mechanical and electrical properties. At 12% EDOT content, the hydrogel had a tensile strength close to 8 MPa, while the electrical conductivity sat at 1.2 S/cm and the elasticity remained constant.

Further functional testing of the sensor with a human finger revealed that it could accurately transform physical pressure changes into sensitive electrical signals. The team subjected the sensor to a wide range of forces and deformations without it tearing or plastically deforming, confirming its toughness and flexibility. It was concluded that the experimental hydrogel could be used to effectively 3D print pressure sensors capable of monitoring human activity. The team hopes to develop the work and eventually apply the technology to stretchable electrical devices and soft robotics.

Further details of the study can be found in the paper titled ‘Tough and conductive polymer hydrogel based on double network for photo-curing 3D printing’. It is co-authored by Xueyuan Ding, Runping Jia, Zuzhong Gan, Yong Du, Dayang Wang, and Xiaowei Xu.

Research into 3D printable hydrogels has made great strides in recent years. Just last month, researchers in Stuttgart 3D printed multimaterial parts with multidirectional stiffness gradients using a cellulose-based hydrogel. By developing a custom G-code incorporating the variation in stiffness throughout the material, the team was able to program a set of varying deformation geometries directly into the samples. Elsewhere, in Illinois, researchers successfully merged a 3D printed hydrogel skeleton with the spinal cord of a rat to create a functional walking ‘spinobot’.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows hydrogel microstructure. Image via Shanghai Institute of Technology.