Scientists from the University of Nottingham have developed a new way to control harmful fungi, without the need to use chemical bioactives like fungicides or antifungals, which can be applied via 3D printing.

In a paper published in Science Advances, experts from the University demonstrate how they have developed an innovative solution to tackle fungi, by passively blocking fungal attachment to surfaces using a coating of (meth)acrylate polymers, and so negating the need to use potentially harmful anti-fungals or other bioactive chemicals.

The polymer solution can be administered either as a spray for crops to prevent fungal infection, or as a material formulation for inkjet-based 3D printing. This can then be used to 3D print medical devices to prevent fungi from forming on their surfaces.

Devising an alternative fungal control strategy

In the paper, the researchers explain that fungi can cause diverse, serious societal and economic problems in the UK and globally. “Fungal infections of humans are associated with high mortality rates (~50% in hospitalized patients), killing more than 1.5 million people annually,” as stated in the research.

As well as leading to fatal diseases in humans, fungi devastate food crops and spoil valuable products and materials. As such, the creation of preventive measures has led to an antifungals/fungicide industry worth around $30bn globally. However, there are tight regulations around the use of fungicides and antifungals and there is also growing resistance of fungi to these agents.

“Antifungal drugs and fungicides provide our first line of defense against fungi. However, efficacy of the current arsenal of approved agents is being eroded by drug resistance. The issues of resistance, tightening antifungal/fungicide regulations, and mounting concerns for human and environmental health issues resulting from excessive chemical use have combined to underscore the need for alternative, sustainable strategies for fungal control,” explain the authors of the paper.

In response, the Nottingham University research team, based in the Schools of Life Sciences, Pharmacy, and Engineering, have developed a novel solution to tackle fungi, as detailed in the study. The method involves passively blocking (i.e., no killing effect) fungal attachment to surfaces using a coating of (meth)acrylate polymers, and so negating the need to use potentially harmful anti-fungals or other bioactive chemicals.

With assistance from prior research, the team were able to identify different combinations of fungicides which worked against fungi, and also produced new understanding of preservative action against spoilage fungi.

Although these advances meant less use of certain fungicides and chemicals, the increasing regulations around usage are preventing the take up of technologies that still rely on bioactive agents, while spread of resistance worsens the problem. Consequently, potential bioactive-free technologies for combatting fungi are highly attractive to the industry.

The Nottingham team’s solution demonstrates an alternative fungal control strategy, which doesn’t have the ‘killing effect’ of fungicides. They identified polymers that resist the attachment of different kinds of fungi, including pathogens.

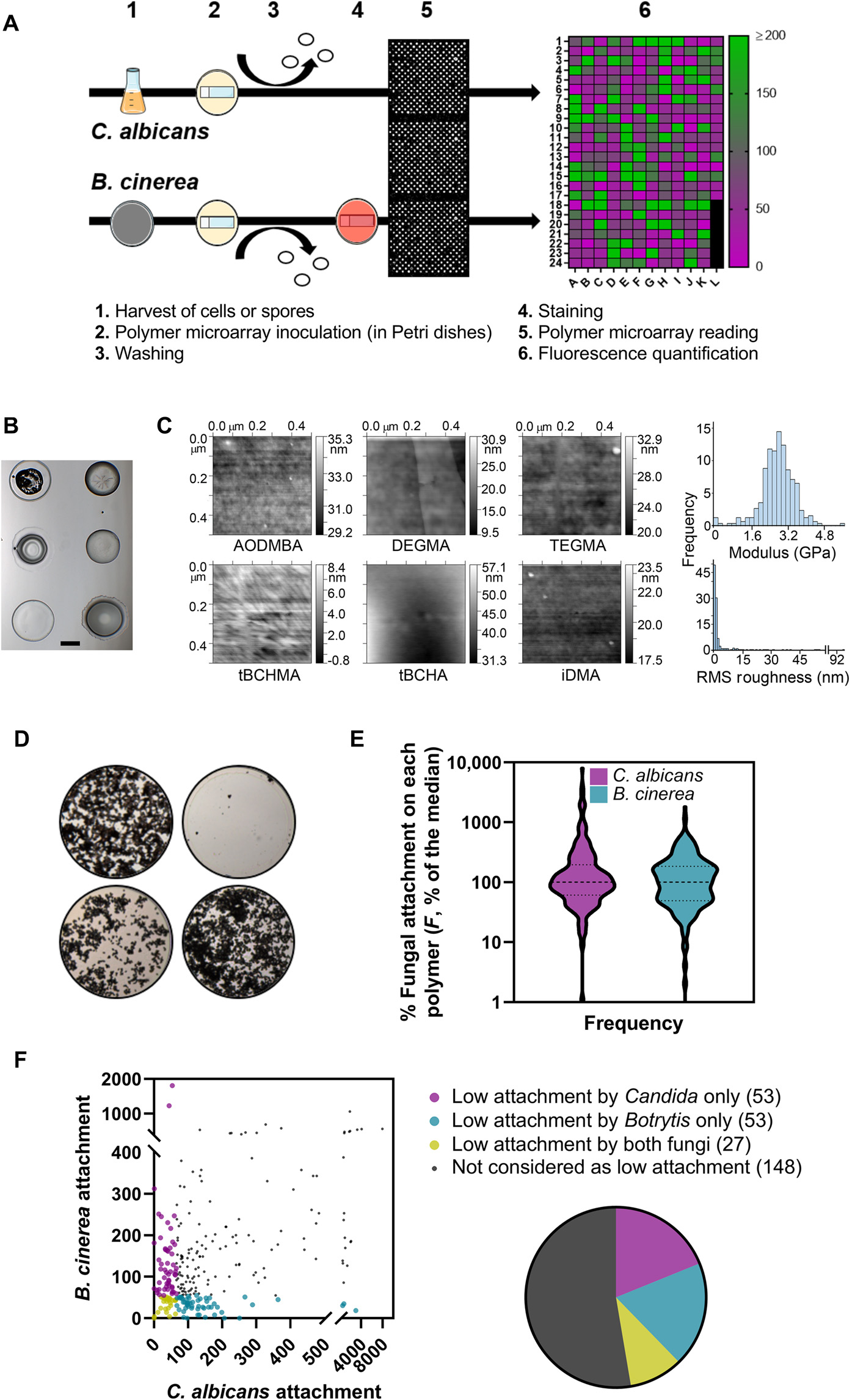

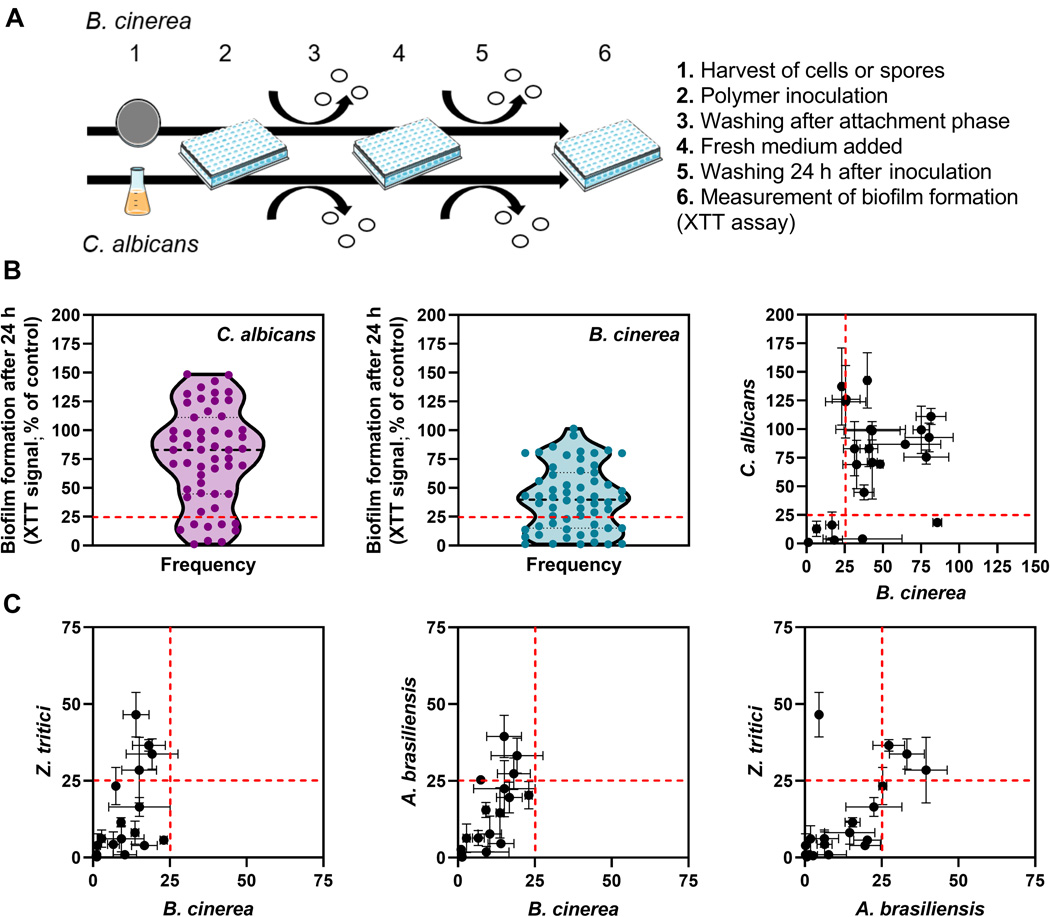

The group of researchers then screened hundreds of (meth)acrylate polymers in high throughput, pinpointing several that reduce attachment of the human pathogen Candida albicans, the crop pathogen Botrytis cinerea, and other forms of fungi. The polymers contained certain chemical features that are associated with weak fungal attachment. The materials were also not toxic, supporting their passive utility.

How 3D printing can prove integral in preventing fungi build-up for medical devices

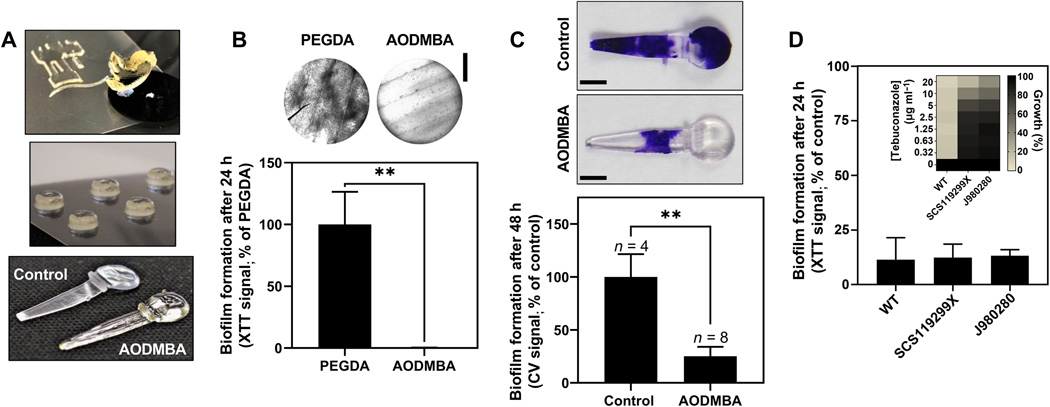

Next, the team developed a formulation with the polymer materials for inkjet-based 3D printing, which can then be used to fabricate specific medical devices for humans. This can be useful in preventing the build-up of Candida albicans, a pathogenic yeast that is found in the gastrointestinal tract and mouth of 40–60 percent of healthy adults. Human pathogens, like Candida albicans, have the potential to form biofilms – a community of microbes – on biomedical devices used in humans.

Therefore, patients are forced to replace devices like voice-prosthesis, a one-way valve placed between the esophagus and trachea to help restore speech after surgery, on a regular basis. However, 3D printed iterations of said medical devices, made from the polymer mix developed by the research team, can potentially prevent the build-up of fungi on hospital and patient medical equipment.

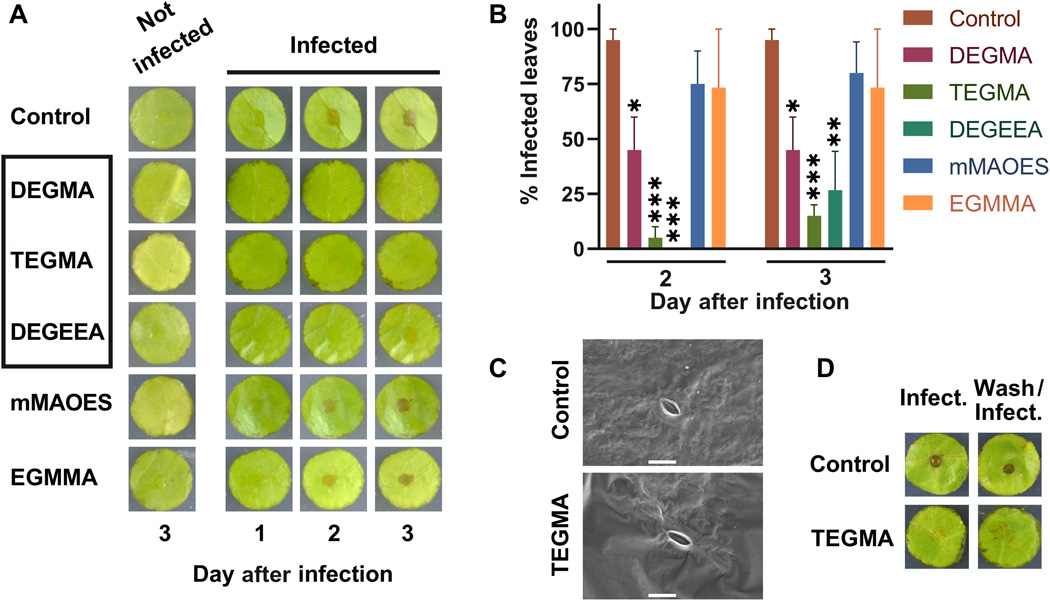

Indeed, the researchers found that 3D printed voice-prosthesis components with their polymer mix showed up to 100 percent reduction in Candida albicans biofilm versus commercial materials. Additionally, spray-coated leaf surfaces resisted fungal infection, with no plant toxicity.

Professor Simon Avery, from the School of Life Sciences at the University and a lead investigator on the paper, stated: “This is the first high-throughput study of polymer chemistries resisting fungal attachment. Our engagement to date with industry has highlighted a clear need for a new approach to control fungi and the major socioeconomic problems that they cause, as the value of existing strategies using bioactives (antifungals, fungicides) is eroded by growing resistance and regulations.”

“This passive, anti-attachment technology that we have been developing addresses this need. We have been able to show that different polymers are effective in resisting diverse fungi that have broad socio-economic impacts.”

The study, “Discovery of (meth)acrylate polymers that resist colonization by fungi associated with pathogenesis and biodeterioration”, is published in Science Advances. It is written by Cindy Vallieres, Andrew L. Hook, Yinfeng He, Valentina Cuzzucoli Crucitti, Grazziela Figueredo, Catheryn R. Davies, Laurence Burroughs, David A. Winkler, Ricky D. Wildman, Derek J. Irvine, Morgan R. Alexander, and Simon V. Avery.

3D printing medical devices with antibacterial materials

Many researchers and organizations have turned to developing antibacterial filaments and materials for 3D printing medical devices and implants. For example, Andaltec, a Spanish research centre focused on plastics, recently announced that it will be developing a new set of active polymers for use in the 3D printing of medical devices. The project, named PoliM3D, will see the characterization of new antibacterial and analgesic filaments for FDM 3D printers. These new filaments will be used to produce custom implants, prosthesis, and surgical tools tailored to individual patients. Furthermore, Scientists from the University of Sheffield have integrated antibacterial properties into polymer powders to create 3D printed parts capable of fighting infectious diseases.

NASA is also testing and funding the development of antibacterial 3D printing materials for medical devices on the International Space Station (ISS). The materials are being developed by Copper 3D, a US-based Chilean 3D printing materials company.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows resistance of AODMBA to C. albicans biofilm formation on 3D printed polymer forms and in drug-resistant isolates. Image via Science Advances.