NASA is testing the suitability of an antibacterial 3D printer filament for use in future space missions. The filament is made by Copper3D, a Chilean company with a base in the USA. The study, conducted in association with the University of Nebraska at Omaha, aims to overcome the health challenges faced by NASA astronauts in space.

3D printed antibacterial prostheses

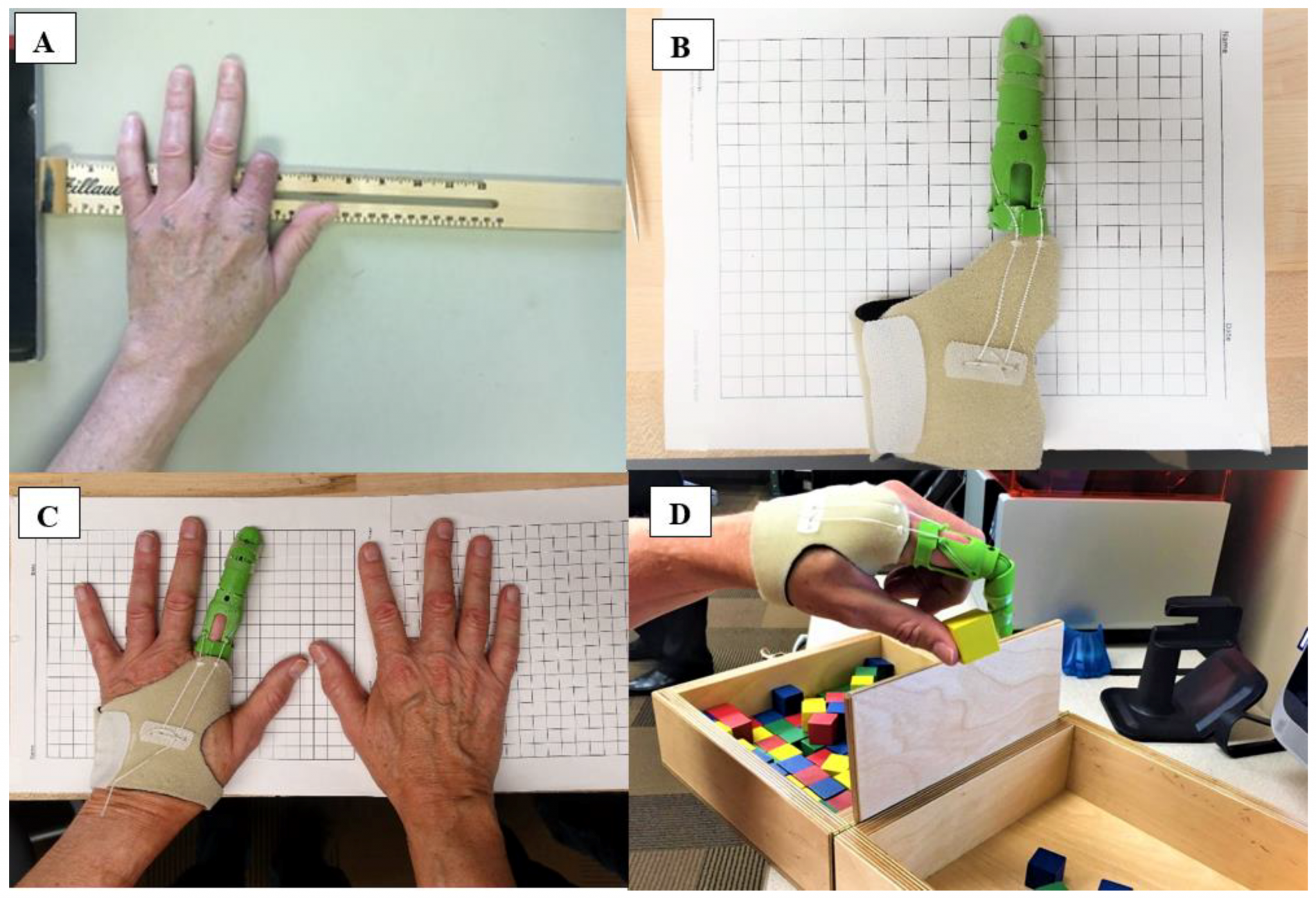

A new research paper ‘3D printed antibacterial prostheses’ published in Applied Sciences journal investigates, “the development of 3D printed prostheses using antibacterial filaments” and the resulting “antibacterial properties of the 3D printed prostheses.” It is hoped that the research will lead to applications including postoperative prostheses, wound dressings, and surgical equipment.

Dr. Jorge Zuniga works in the Department of Biomechanics at the University of Nebraska and is a scientific collaborator of Copper3D. Working with the 3D printable PLACTIVE material, a polylactic acid polymer with 1% antibacterial nanoparticles, Dr. Zuniga manufactured the 3D printed finger prostheses.

Made by Copper3D, PLACTIVE contains copper nanoparticles which are effective in removing viruses, fungi and bacteria, and are harmless to humans. It is a low-cost, biodegradable material which possess thermoforming characteristics that assist post-processing and definite adjustments of 3D printed prostheses.

The research findings showed that PLACTIVE is up to 99.99% effective against Staphylococcus aureus and Escherichia coli (E.coli) bacteria. The antibacterial properties of the polymer were not affected by extrusion, however, the longevity of those properties are yet to be fully tested.

Daniel Martínez, Director of Innovation and co-founder of Copper3D, comments, “Our main focus has been the development of antibacterial materials with applications in the field of Medicine and Rehabilitation, such as medical/surgical instruments, orthoses, prostheses, applications in the dental world, and healing of complex wounds.”

“But now we want to go a step further and verify the potential of this technology in other types of challenges associated with the problems of the future of long-duration space missions.”

NASA and antibacterial 3D printing material

With an eye on long-term missions to Mars, NASA is keen address health challenges faced by astronauts spending considerable time in space. For example, immediate access to medical instruments manufactured ‘on demand’, prosthetics, orthoses, emergency treatment or rapid wound closure amongst others could prove vital. Zuniga stated:

“This study will also set the scientific basis for future studies on the impact of this new technology on countless new antibacterial applications that solve serious health and functional problems both on earth and in space.”

Subsequently, NASA Nebraska Space Grant has launched a collaboration with the University of Nebraska at Omaha and Copper3D. The study addresses use of advanced antibacterial 3D printing material for customized medical applications during NASA’s space missions.

Andrés Acuña, CEO and co-founder of Copper3D, says, “We are very excited about the results that may come out of this study with Dr. Jorge Zuniga, the University of Nebraska at Omaha and NASA. We think that this collaboration could be maintained over time to explore new technologies in the field of Additive Manufacturing that can save lives in complex contexts such as intra-hospital infections and environments as hostile as long duration space missions.”

This October, Copper3D will launch its new e-store on Amazon, and PLACTIVE will be available for purchase. The material will also be available through resellers.

For the latest news on antibacterial 3D printing materials, subscribe to the 3D Printing Industry newsletter.

For more updates follow us on Twitter, and like us on Facebook

If you want to advance your career in additive manufacturing or recruiting for 3D Printing Jobs,visit our jobs site now.