NASA has awarded a $127,000 Small Business Technology Transfer (STTR) Phase I grant to the Arizona State University (ASU) and Phoenix Analysis and Design Technologies (PADT), an engineering service company based in Tempe, Arizona for advanced 3D printing research.

ASU and PADT are currently cooperating to accelerate the development of bioinspired 3D printed structures which will ultimately enable strong and lightweight parts for use in spacecrafts.

“We’re honored to continue advanced research on biomimicry with our good friends and partners at ASU,” said Rey Chu, Principal and Co-Founder of PADT.

“With our combined expertise in 3D printing and computer modeling, we feel that our research will provide a breakthrough in the way that we design objects for NASA, and our broad range of product manufacturing clients.”

Bioinspired 3D printing

The ability to mimic the natural strength and composition of biological materials through additive manufacturing has enabled novel structures such as a 3D printed oyster-inspired “brick-and-mortar” construct and a 3D printed alligator-inspired armour gloves.

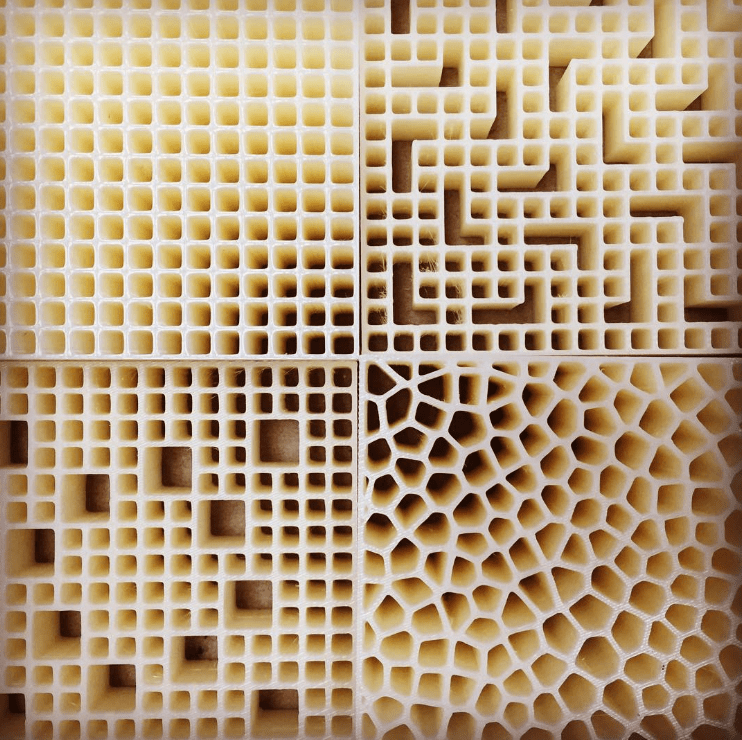

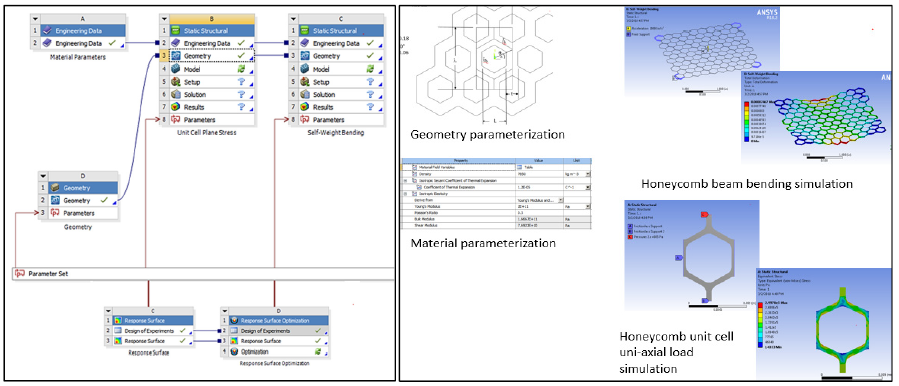

Now, ASU and PDAT, are looking to replicate the hexahedron structures found in honeycombs and bamboo using additive manufacturing. Which will provide lightweight strength within carbon fiber composite aircraft and spacecraft components.

“New technologies in imaging and manufacturing, including 3D printing, are opening possibilities for mimicking biological structures in a way that has been unprecedented in human history,” said Dhruv Bhate, Associate Professor of Additive Manufacturing at ASU.

“Our ability to build resilient structures while significantly reducing the weight will benefit product designers and manufacturers who leverage the technology.”

As a result of further biomimicry research, ASU and PADT will design and manufacture high-performance materials for use in heat exchanges, lightweight structures, and space debris resistant skins. Depending on the success of this initial research first phase, the partners will be eligible for a second, larger grant from NASA.

Phoenix Analysis and Design Technologies aids the Orion Mission

Recently, PADT, Lockheed Martin, and Stratasys partnered to help NASA develop over 100 3D printed parts for its manned-spaceflight to Mars, the Orion Mission. This collaboration leverages advanced materials from Stratasys, such as the ULTEM 9085 a flame-retardant high-performance thermoplastic, its high-performance, PEKK-based thermoplastic Antero 800NA. The materials used are well-suited for NASA’s heat and chemical resistance requirements and can withstand high mechanical loads.

Commenting on the ASU and PADT partnership as well as NASA’s STTR grant, Ann McKenna, School Director and Professor, Ira A. Fulton Schools of Engineering, ASU stated:

“PADT has been an excellent partner to ASU and its students as we explore the innovative nature of 3D printing. Between the STTR grant and partnering to open our state-of-the-art Additive Manufacturing Center, we’re proud of what we have been able to accomplish in this community together.”

Looking for the latest news in 3D printing? Subscribe to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

On the lookout for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows 3D printed prototypes of honeycomb structures. Photo via PADT.