A collaboration between the Australian Nuclear Science and Technology Organization (ANSTO), the Indian Institute of Technology Bombay (IIT Bombay), and Monash University has discerned the perfect balance of stresses in DED 3D printed coating. Realized as a theoretical model, the critical deposition height of DED layers is a step towards improving the longevity of components repaired using 3D printing.

3D printed maintenance and repair

Designed for metal 3D printing on conformal surfaces, directed energy deposition (DED), and related technologies like laser metal deposition (LMD), are commonly used for component repair.

New Mexico headquartered Optomec is one of the commercial providers of DED technology, along with Trumpf in Germany, the UK’s TWI, and French company BeAM, which was recently acquired by AddUp.

In one case from a team at Rochester Institute of Technology (RIT), New York, a CNC machine retrofitted with Optomec’s LENS engine was used to replace the tooth of a damaged machine gear. As another example, a team at Royal Melbourne Institute of Technology (RMIT) is applying DED for aircraft maintenance and repair.

“Directed energy deposition methods have a huge potential in repair and re-manufacturing of aerospace components, dies and moulds which undergo damage due to cyclic thermomechanical loading,” explains Professor Ramesh Singh from IIT Bombay.

“However, the presence of tensile residual stresses in the deposited layer will reduce the fatigue life of a restored component. “

Eradicating tensile residual stresses

Residual stresses exist as tensile residual stresses, detrimental to the overall part integrity, and compressive residual stresses, which are conversely beneficial to the structure.

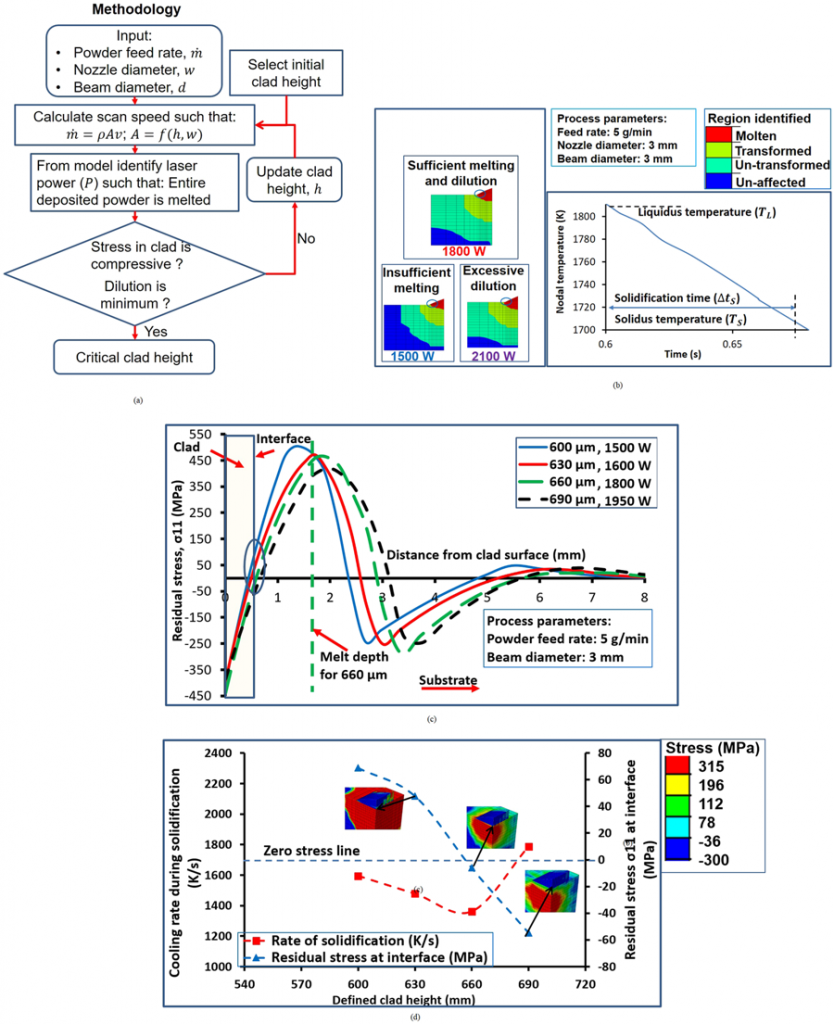

Both kinds can be estimated using theoretical models of thermomechanical properties. However, the ANSTO collaborative study found that, between a substrate and a deposited layer, such models often overestimate tensile stresses while underestimating compressive stresses.

To support the thermomechanical model of predicted residual stresses, the researchers employ an x-ray diffraction system. A method of non-destructive testing (NDT), these x-rays are used verify residual strains in the substrate and a 3D printed layer or coating.

“Using the Kowari strain scanning instrument we were able to identify triaxial residual stresses in the deposited layers, which verified the locations predicted by the model,” explains ANSTO Research Scientist and Industrial Liaison Manager Dr. Anna Paradowska. With this data, the team were able to determine “a critical deposition height, which ensures compressive residual stresses in the deposited layer.”

As further explained in the abstract of the study, “Any lower deposition height will result in tensile residual stresses and higher deposition height will result in excessive dilution (substrate melting).”

Optimizing additive manufacturing

Other projects harnessing x-ray diffraction methods to improve metal 3D printing processes include a Lawrence Livermore National Laboratory undertaking at the SLAC National Accelerator Laboratory and the UK AMAZE project on laser additive manufacturing.

Underlining the research discussed in this article, Dr. Paradowska says, “Understanding the stresses and being able to predict them is very important for additive manufacturing industry. [This] validated model is very beneficial as further optimization of the manufacturing process using this model will be cost effective and saves time.”

ANSTO, IIT Bombay and Monash’s latest discoveries are published online in Scientific Reports journal. The research article titled “Critical deposition height for sustainable restoration via laser additive manufacturing” is co-authored by Santanu Paul, Ramesh Singh, Wenyi Yan, Indradev Samajdar, Anna Paradowska, Khushahal Thool and Mark Reid.

For all the most recent research updates subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Seeking jobs in academia? Create a free profile on 3D Printing Jobs, or advertise to find expertise in your area.

Featured image shows the Kowari Strain Scanner. Photo via ANSTO