A team of researchers from the University of Washington and Sandia National Laboratories have 3D printed a working carbon monoxide detector. By decorating a reduced graphene oxide (rGO) sensor medium with a printed tin dioxide (SnO2) semiconductor catalyst, the team was able to produce a detector that functioned at room temperature with a fast response time.

Carbon monoxide poisoning

According to the CDC, there are at least 430 annual deaths in the US alone from carbon monoxide poisoning, with another 50,000 trips to the emergency department as a result of the gas. Carbon monoxide is near undetectable due to a lack of odor, meaning it can pose a serious risk to human health. It is usually produced as a result of incomplete combustion, whereby the oxygen supply of a flame is too low for complete combustion to take place.

While tin dioxide-based carbon monoxide detectors are popular today, the manufacturing of these devices can be costly and time-consuming. On top of this, the semiconductor material usually has to be heated to temperatures above 400°C to be effective. The high temperature requirements mean that thin, compact, and flexible devices are difficult to manufacture.

Tin dioxide-graphene nanoink

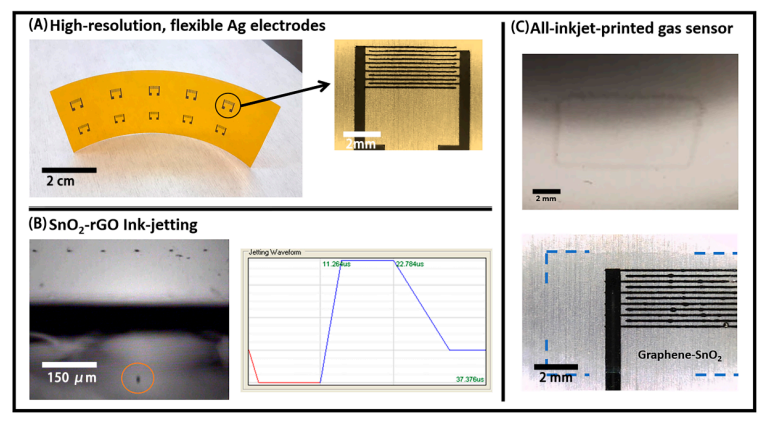

The researchers started by using a modified solvothermal aerogel process to decorate reduced graphene oxide sheets with tin dioxide at the nanoscale. The resulting purified aerogel was re-dispersed and ground using a pestle and mortar. It was mixed with a final solvent to produce a tin dioxide-graphene nanoink.

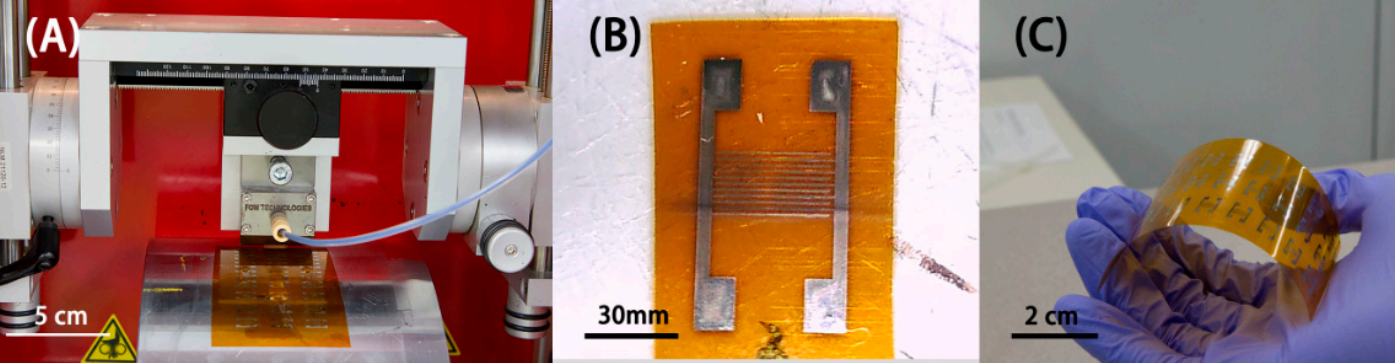

To fabricate the sensors, the team inkjet printed silver electrodes on polymer substrates with linewidths in the 100 micron region. The tin dioxide-graphene nanoink was then inkjet printed on top of the silver electrodes to coat them. The whole structure was then heat treated to anneal it and further reduce the graphene so it would be more effective at room temperature.

When it came time to test the sensors, the team managed to detect 50 ppm of carbon monoxide in the presence of nitrogen. This was with a response of 15%, a response time of 4.5s, and a recovery time of 12s. The results, according to the researchers, showed that the printed sensors were superior to other previously tested sensors operating at room temperature. The team therefore concluded that thin and flexible carbon monoxide sensors could be 3D printed with scalable, cost-effective protocols, adding another potential application to AM’s rapidly growing list of uses.

Further details of the study can be found in the paper titled ‘Additive Manufacturing of a Flexible Carbon Monoxide Sensor Based on a SnO2-Graphene Nanoink’. It is co-authored by Jialin Zuo, Sean Tavakoli, Deepakkrishna Mathavakrishnan, Taichong Ma, Matthew Lim, Brandon Rotondo, Peter Pauzauskie, Felippe Pavinatto, and Devin MacKenzie.

Research into 3D printed sensors is becoming more and more common as the capabilities of 3D printing grow. Recently, a team of researchers in China 3D printed a tough and conductive polymer hydrogel to produce flexible wearable motion sensors. Comprehensive testing of the sensors revealed that they could accurately transform physical pressure changes into sensitive electrical signals. Elsewhere, in Korea, researchers 3D printed a set of highly-sensitive, wearable biosensors capable of detecting actively changing body strain signals.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows fabrication of the sensors. Photo via University of Washington.