A team of researchers from Sungkyunkwan University have used a commercially available inkjet printhead to fabricate wearable medical biosensors for personalized health monitoring. Using a soft, flexible silicone elastomer with a sugar scaffold, the team was able to print high-resolution features in a lightweight, electrically conductive package. The moldable biosensors are being used to detect actively changing body strain signals as well as passively changing electromyography (EMG), electrodermal activity (EDA), and electroencephalogram (EEG) signals.

Personalized medical care

3D printing for personalized medical care will always require a high level of customizability. For drug delivery devices such as tablets, the dosages will be custom whereas for pre-surgery anatomical models, the patient’s contours will be unique to them. Similarly, 3D printed wearable biosensors will have to conform to the shape of the patient’s body and stay there. For this, they have to be flexible, lightweight, and non-toxic. To detect changes in electrical signals under the skin, they will also have to be highly sensitive and, of course, electrically conductive.

3D printing wearable biosensors

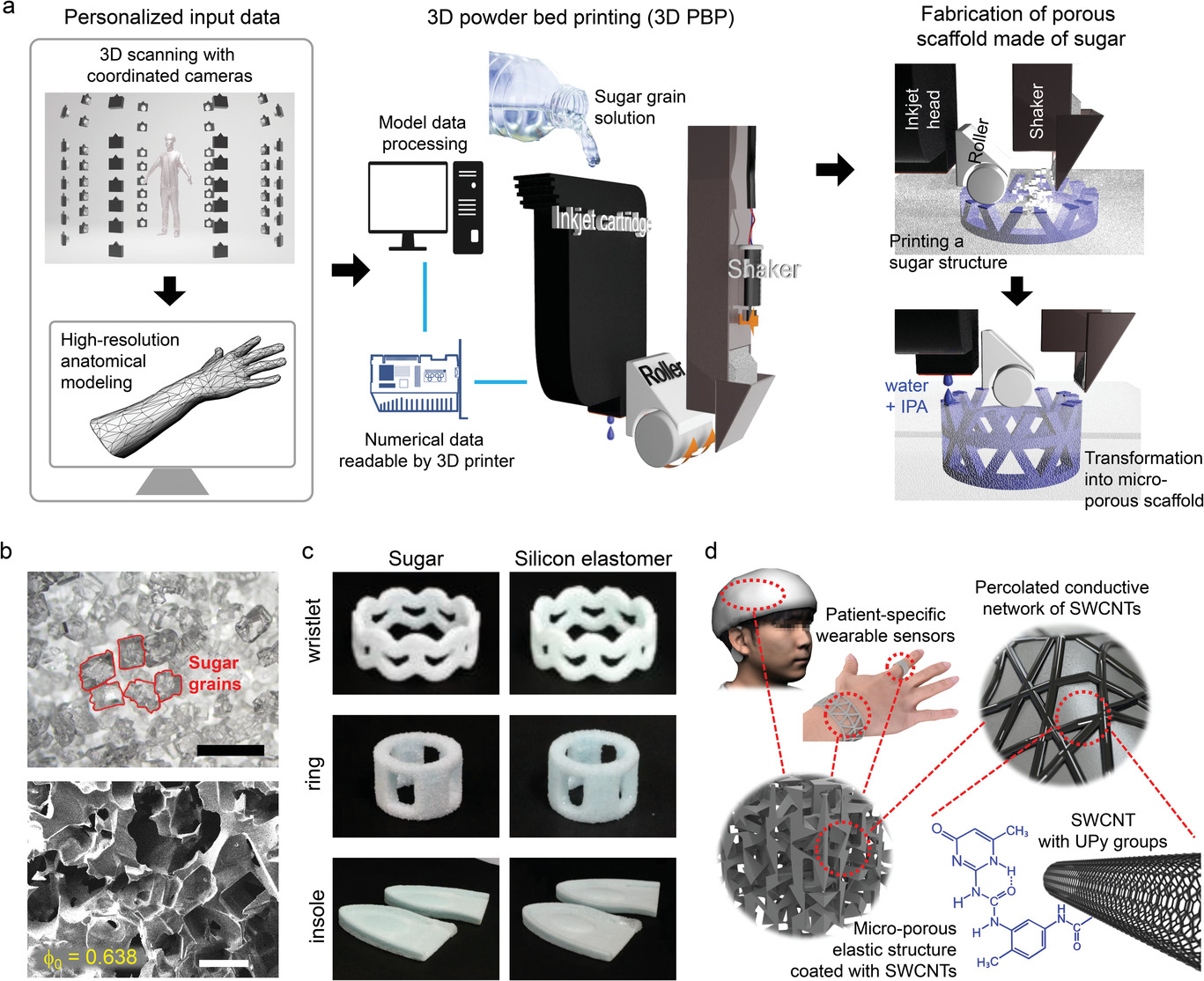

With the extensive set of requirements in mind, the Korean researchers first acquired some 3D anatomical body scans from volunteer patients. These scans went on to be used as a point of reference to model the personalized wearable biosensors. The team 3D printed a porous sugar scaffold for each of the wearable devices and injected the pores with a silicone elastomer filler (among other additives) to give the sensors their elasticity. Once the sugar scaffolds dissolved, all that was left was a low density, highly flexible microcellular network‐type interconnected conductive material.

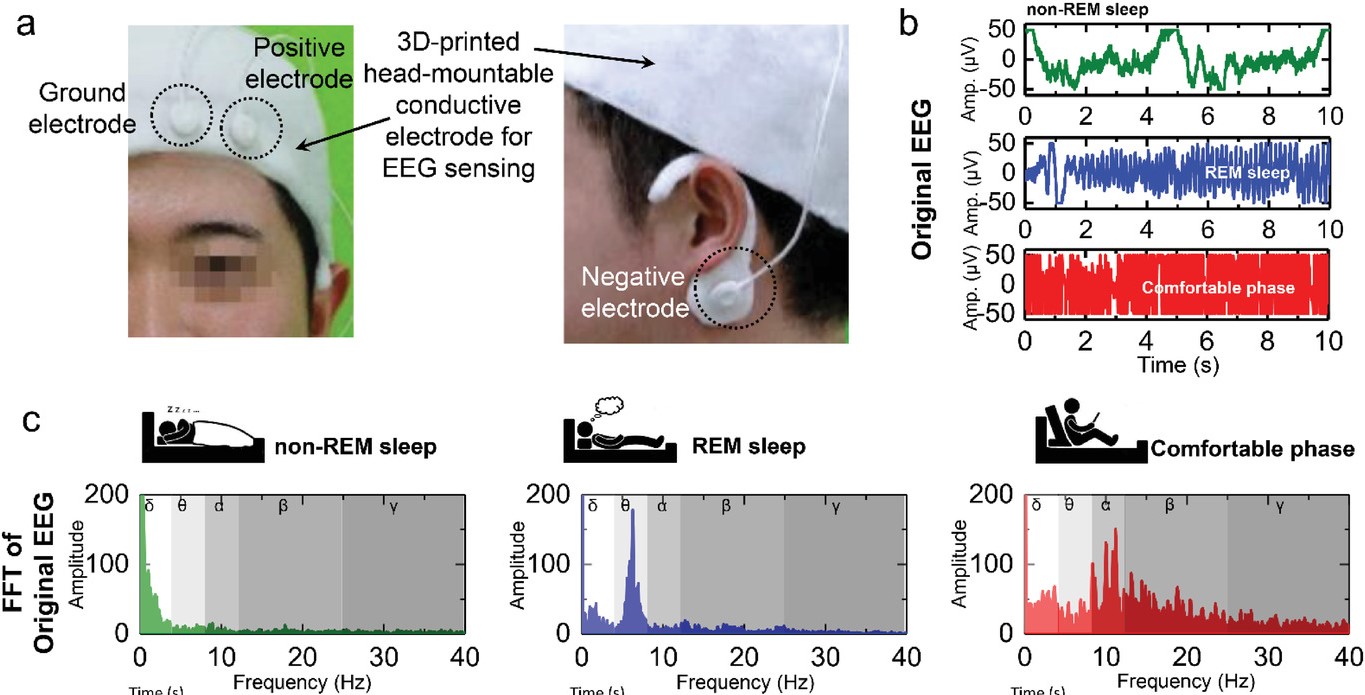

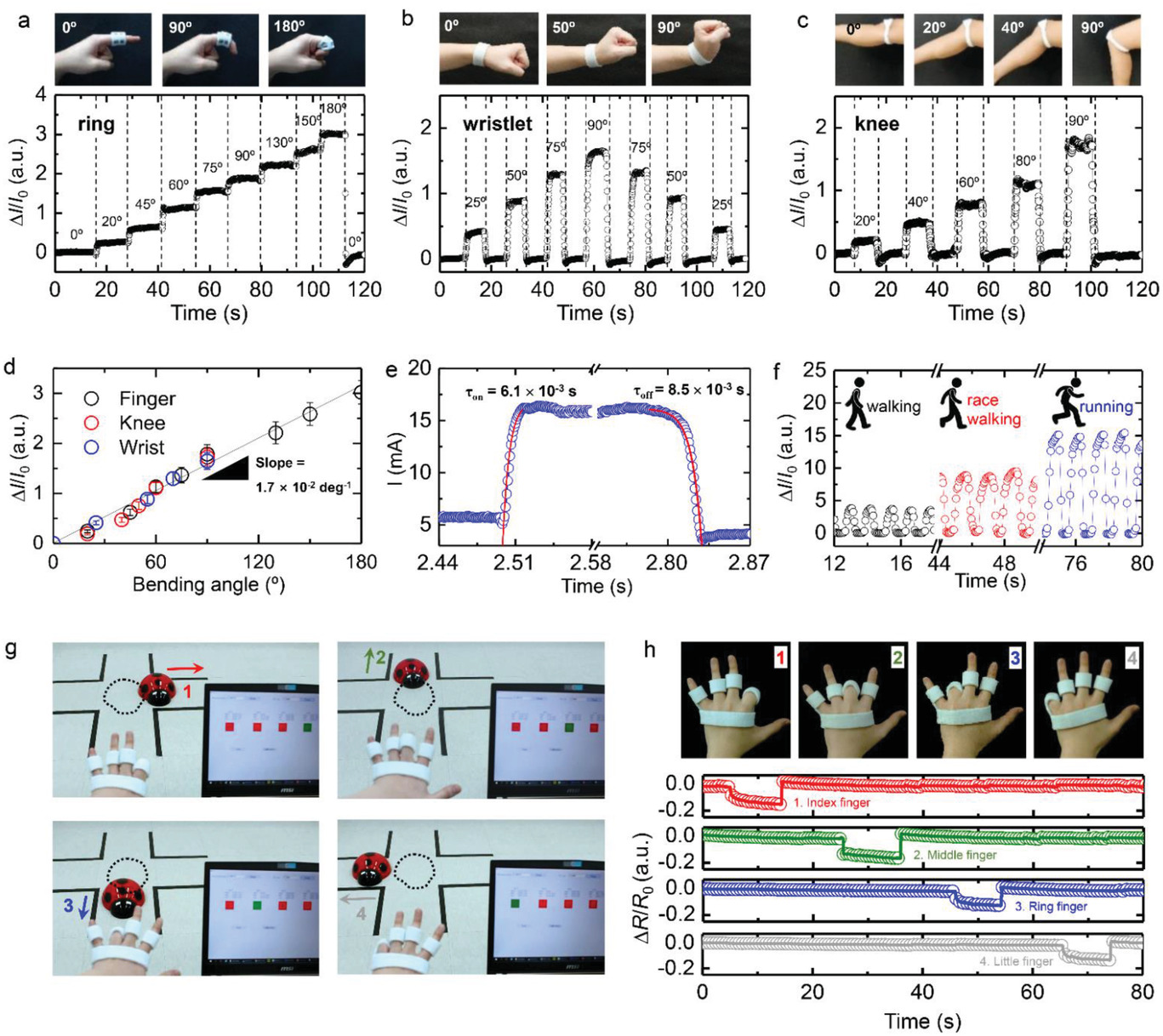

A number of experiments were conducted to test the functionality of the newly printed biosensors including a comprehensive sleep study measuring brainwaves and a treadmill study measuring neuron activity in muscle tissue. The researchers concluded that the patient-specific 3D printed sensors were highly sensitive to minute electrical signal changes under the skin, in the muscles, and in the brains of the volunteers. They were able to monitor the rapidly changing human body signals in real time to a high degree of precision, adding another application to 3D printing’s growing list of uses. The researchers intend to develop the technology further to encompass a number of other personalized point-of-care diagnostics.

Further details of the study can be found in the paper titled ‘3D‐Printed Sugar Scaffold for High‐Precision and Highly Sensitive Active and Passive Wearable Sensors’. It is co-authored by Dong Hae Ho, Panuk Hong, Joong Tark Han, Sang‐Youn Kim, S. Joon Kwon, and Jeong Ho Cho.

The 3D printing of sensors is one of those novel applications that is quickly gaining traction from researchers and companies alike. Earlier this month, REHAU, a leading polymer manufacturer, successfully 3D printed a touch sensor using Nano Dimension’s AM electronics technology. By integrating an electronic circuit, REHAU was able to functionalize one of its premium polymer materials as part of its ‘Electronics into Polymers’ program. Elsewhere, at the University of Lincoln, researchers have prototyped a 3D printed, sensor-operated prosthetic arm designed for toddlers.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the process of 3D printing the wearable sensors. Image via SKKU.