The applications for 3D printing are limitless. Innovators are constantly coming up with new applications and designs for the technology; however, one of the main limitations to desktop FFF 3D printing’s use is often a filament’s material properties. Kai Parthy has been a powerhouse when it comes to inventing new fused-filament deposition materials, inventing LayWoo-d3, BendLay, LayBrick, Poro-Lay, and more. Now, Parthy has come up with a revolutionary new material called: MoldLay.

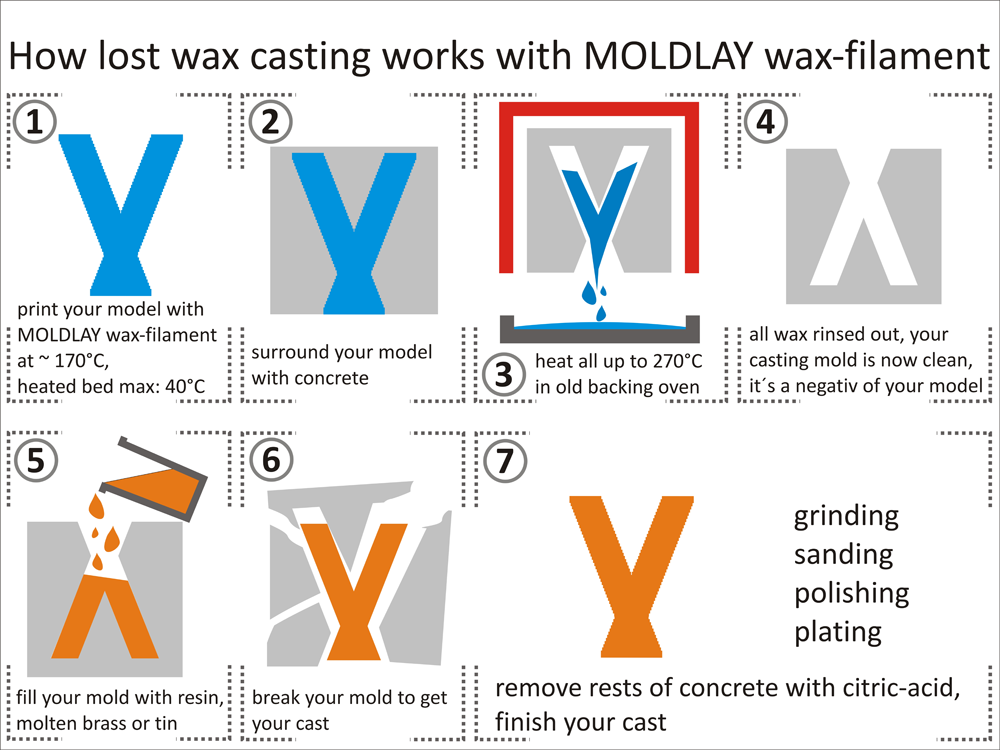

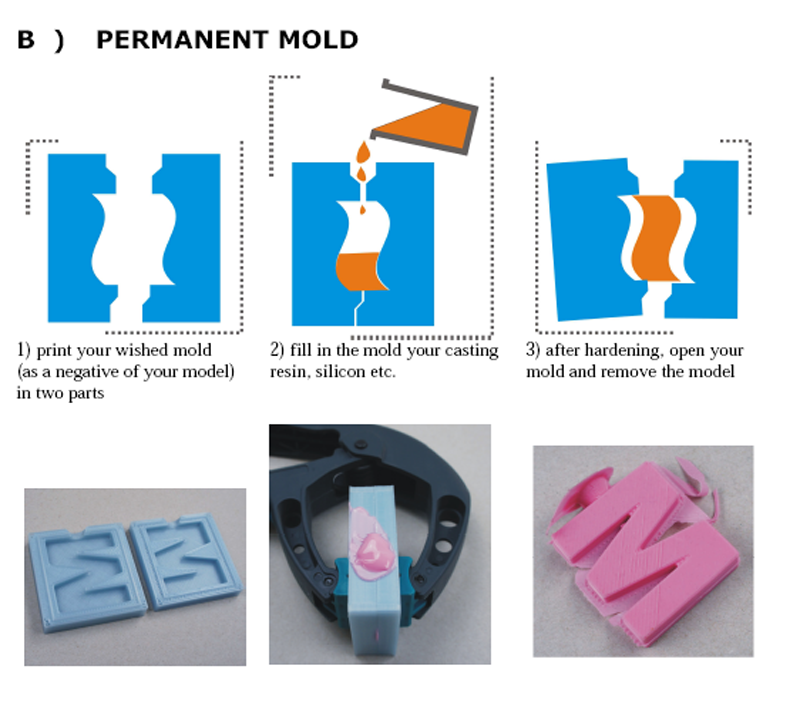

MoldLay is ideal for both permanent casting and investment (lost-wax) casting. With a printing temperature of 170-180°C, you may be reminded of the conditions used for printing with PLA. The similarities that MoldLay has with standard filaments ends there, however. The main difference between MoldLay and other plastics is the material’s transition into an ultra low viscosity fluid when heated to 270°C. This allows it to effortlessly flow out of a mold’s cavity. Ordinary baking ovens can achieve this temperature, so there’s no need to upgrade existing equipment. Other plastics would also melt, but their higher viscosity would prevent them from cleanly vacating the mold. And, if the oven is heated even higher, these plastics can be burned off more completely, but create noxious fumes in the process.

Among the biggest headaches for 3D printer users is preventing objects from warping on the print bed. The most common preventive measure used to prevent objects from distorting during cooling, is the use of a heated bed. Parthy describes MoldLay as having “one of the lowest warping effects ever to [go] through [his] hands.” It’s so resistant to warping, that a heated bed isn’t needed.

Prices haven’t yet been released for MoldLay, but Parthy expects the filament to be available this month, so be sure to check your local seller!