Merry Christmas from Kai Parthy! After inventing the concrete-like LAYBRICK and wood-like LAYWOO-D3 filaments, the man has proven himself a whiz with textures and material engineering once again with the first in a new series of filaments, PORO-LAY. PORO-LAY is a foamy, felty filament with a porous structure. As Kai describes, “Today I would like to introduce to the readership the opposite of filled materials. A series of materials which are filled with emptiness, namely pores.”

The new line consists of four different filaments: LAY-FELT, LAY-TEKKKS, LAY-FOMM, GEL-LAY. LAY-FELT and LAY-TEKKKS are similarly felt-like materials though LAY-TEKKKS is thinner and more fibrous. LAY-FOMM and GEL-LAY are foamy and gel-like respectively. The composition of the materials follows a simple equation. Kai takes two different materials, “A) a functional component, for example an Elastomer (i.e. a rubberlike)” and “B) a soluble component (could be PVA, or Sugar, or salt, or soluble resins).” He blends them together, granulates them, and then extrudes them into a filament for FFF 3D printing. Once an object is printed from a filament in the PORO-LAY series, it is then soaked in water for a given amount of time, dissolving component B and leaving A intact. Watch a video of the series here:

Kai explains that LAY-FELT may be used for semi-permeable membranes and filters, artificial paper and “future cloths”. LAY-TEKKKS May also be good for making future cloths, tissue and “orientated” and “stacked” fibrws. LAY-FOMM might be ideal for soft rubber-like applications, such as bendable suits and sponge-like objects, ink-reservoirs, bio-cells, micro-foam and elastics. GEL-LAY can be useful to illustrate biomechanics or as a simulation muscle, particularly as an underwater material. In the above video, Kai uses an octopus as an example of a marine creature whose movement could be demonstrated with this material.

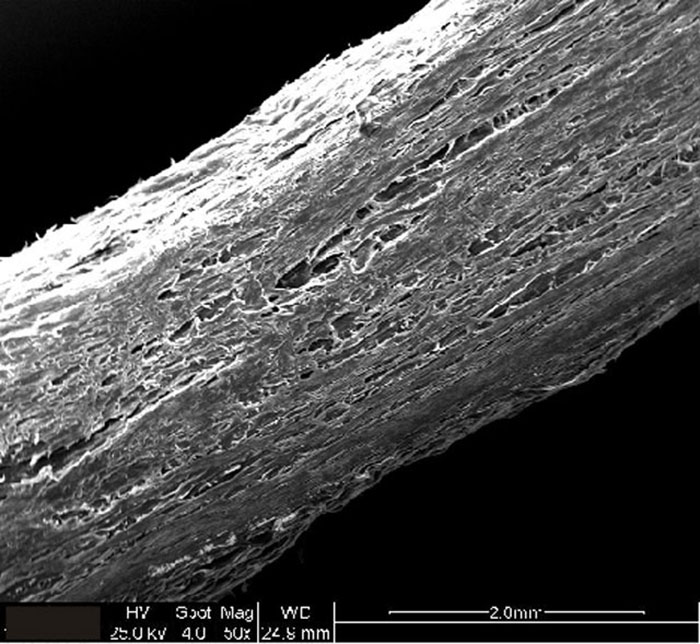

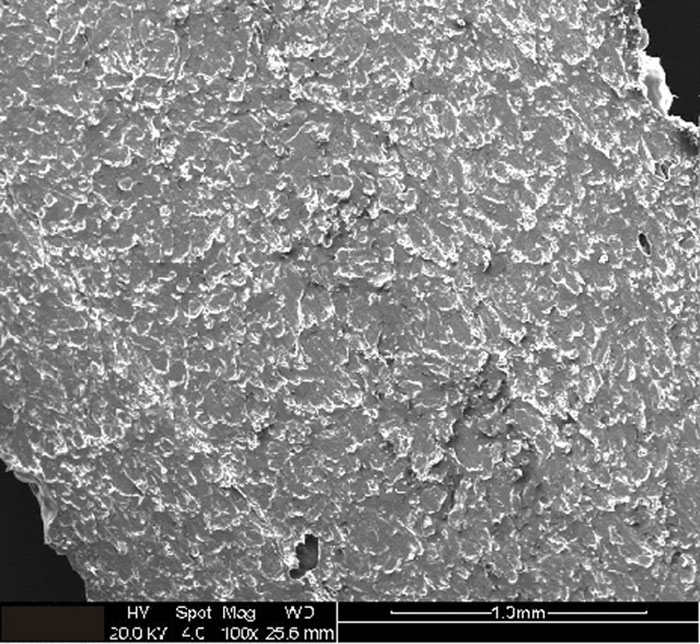

Kai believes that the PORO-LAY filaments will be ready for sale in Q1 or Q2 of 2014 and that interested customers may even ask for industry-specific modifications. Below there are pictures of LAY-FOMM captured under various magnifications of a microscope.

The inventor of the various LAY filaments is still a bit of a mystery to me, but Kai and I are in the process of conducting an interview, so we’ll get to learn a little but more about him and what materials he has in store next year!