Health Canada, a department of the Canadian government, has issued new guidance for the 3D printing of medical devices.

Aligning closely with established international advisory on the subject, the guidelines outline the information required for the manufacture of moderate – high risk devices, including orthopedic implants, and pacemakers. It has been deemed the “first phase” of a developing 3D printing policy for the nation. As stated by the department, “Health Canada is committed to supporting the integration of 3D printed technologies into health care systems in Canada, and providing Canadians with the highest possible quality of care.”

“[…] Due to the fast-changing technological environment, Health Canada will continue to adapt its policy approach to 3D printing as issues on the topic evolve.”

3D printing’s medical impact

Medical is one of the key verticals currently targeted within the 3D printing industry. In 2018, Belgian software and 3D printing service provider Materialise became the first company in the world to receive FDA clearance for a program designed to 3D print anatomical models. Since then, the same company has been given the authority to validate 3D printers for use in hospitals. Also noticing the value of the 3D printed anatomical models, 3D Systems has launched a dedicated on demand service for their production.

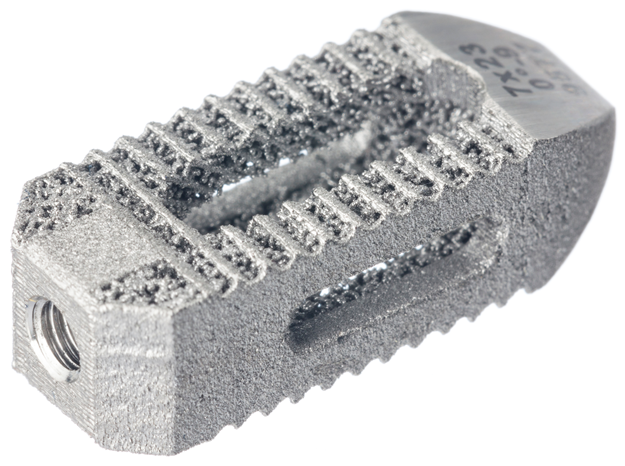

When fabricating devices for direct contact with the human body, spinal implants have been one of the most populous areas of 3D printing’s application. Indicating some consolidation within this particular part of the market, FORTUNE 500 medical technology firm Stryker recently acquired K2M which specialized in the 3D printed production of spinal implants.

As a longstanding customer of Arcam, now a GE Additive company, Global medical device company LimaCorporate has been producing orthopedic implants since 2007.

These and many more companies, including Renishaw, Aurora Labs, and Tangible Solutions, show the impact that 3D printing is having on the healthcare industry. In light of such changes, the FDA issued its guidance for the 3D printing of medical devices in 2017. The agency has also issued millions of dollars in grants to fund the development of 3D printing in medical.

Health Canada’s 3D printed medical device guidance

Health Canada published the first draft of its 3D printed medical device guidance in November 2018. In the past several months it has undergone revisions on the advice of medical professionals. It is now published as Guidance Document – Supporting Evidence for Implantable Medical Devices Manufactured by 3D Printing.

A comprehensive document, the guidance informs manufacturers of all the information to include in a Medical Device License (MDL) application. In addition to the standard information required for conventionally made devices, these 3D printed objects require the following:

– An overview of 3D printing process

– Key device design parameters

– Design parameters altered to meet patient-matched specifications

– A description of critical features

In addition, all manufacturers should have undergone Health Canada preclinical performance testing for the devices and give overviews of the software-related workflows used to make them. Clinical data is also needed for some 3D printed devices “utilizing novel designs, materials or intended uses.”

The guidelines are intended for any Class III (moderate risk) and Class IV (high risk) medical devices made using 3D printing, and do not cover the production of anatomical models, standalone software, 3D bioprinted objects, or patient-specific devices. Patient-specific devices would require a separate classification on an as-needs basis. The guidelines are applicable to the volume production of 3D printed medical devices that have an equivalent already on the market, e.g. spine implants, hip cups and stents.

Vote for your 2019 Medical Application of the Year in the 3D Printing Industry Awards.

For more of the latest 3D printing medical news subscribe to the daily 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.

Featured image shows a full build plate of acetabular cups produced using 3Dxpert software. Photo via 3D Systems