From the landmark case of the conjoined McDonald Twins, to 3D printing over 600,000 medical devices to date, 3D Systems (NYSE:DDD) has launched its On Demand Anatomical Modeling Service.

A service for medical professionals, On Demand Anatomical Modeling makes custom 3D printed models to be used in surgical planning and patient education.

“For more than 25 years, 3D Systems has assisted medical professionals through the combination of our anatomical modeling experience and our 3D printing expertise,” comments Katie Weimer, Vice President, medical devices at 3D Systems.

“The healthcare industry is seeing the benefits provided through 3D printed anatomical models, and we are dedicated to continuing to expand our healthcare offerings to meet market needs.”

3D printed medical devices on demand

3D Systems’ On Demand Anatomical Modeling Service is accessed by a customer uploading a .ply, .stl, or .obj file to the platform. This file is either prepared by the user in a third party program or, for a digital model generated directly from standard DICOM (Digital Imaging and Communications in Medicine), the user can use 3D Systems’ D2P (DICOM to Print) software.

From there, the customer selects from four material options, based on the application:

– SLA Translucent – sterilizable, 3D printed on ProJet/ProX/Fab Pro, suitable for providing a clear view of internal vessels.

– SLA Opaque – also from the ProJet/ProX/Fab Pro, giving an accurate demonstration of a part, i.e. broken bone.

– A combination of flexible and rigid materials – made using MJP and applied in functional/planning cases.

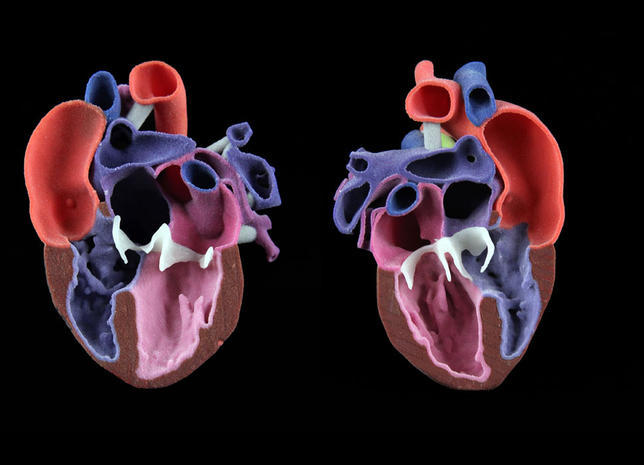

– Or color jet printed (CJP) models, giving a clear, color coded view of each different segment of an organ.

The complete package

Based on the material and specific area of interest in the model, customers can then select and instant quote. Once confirmed the order is is placed. The model then takes an average of 5 working days to arrive.

For a full service, 3D Systems also offers virtual surgical guidance, and professional anatomical modeling services to help customers prepare crucial files. These models can be made using CT and MRI scan data.

Accessible 3D printing

According to Weimer, the On Demand Anatomical Modeling service will make “3D printed models easier and more accessible to a broader range of the healthcare community.”

In a recent report from SME, Weimer also contributed to a view that the industry see a rise in medical 3D printing throughout 2018.

“Today, the healthcare 3D printing industry largely uses legacy industrial prototyping materials,” Weimer commented, “As the industry evolves, I believe we will have a bigger impact on patient care when our materials better replicate the human body.”

For more medical 3D printing updates subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Search and post 3D Printing Jobs here.

Featured image shows 3D printed anatomical models. Photo via 3D Systems