San Francisco biotechnology company Prellis Biologics, has reported record speeds in tissue 3D printing using its holographic technology.

According to Dr. Melanie Matheu, co-founder and CEO of the company, “A major goal in tissue engineering is to create viable human organs, but nobody could print tissue with the speed and resolution needed to form viable capillaries,”

“At Prellis, we’ve now developed that technology, paving the way for important medical advances and, ultimately, functional organ replacements.”

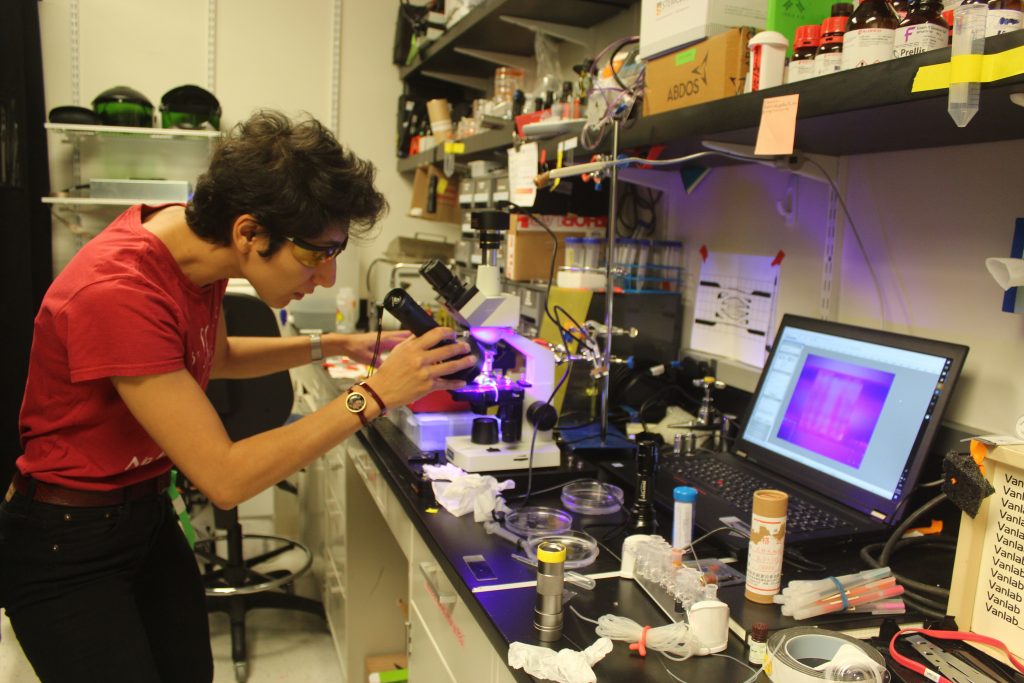

3D printing capillary structure using Prellis Biologics’ holographic technology. Image via Prellis Biologics

Holographic 3D bioprinting

3D printing at Prellis is performed by a laser-based process capable of curing liquid to solid in under less than 5 milliseconds of exposure time.

The technology is used to 3D print fine capillaries, that deliver nutrients to cells, and scaffolds, that help support the growth of cells into a 3D tissue.

Instead of post-seeding the scaffolds and capillaries with cells, the live matter is actually mixed into the print material. To avoid any cell damage due to light exposure, Prellis uses a far-red laser light to cure the material.

“A kidney in 12 hours or less”

The key benefits of the Prellis process are that it 3D prints at a high resolution, (producing feature sizes as small as 0.5 microns) and high speed, accounting for the rapid deterioration of live cells, which would die in less than 30 minutes without nutrients.

Dr. Matheu explains “The speed we can achieve is limited only by the configuration of the optical system. We are now exploring custom optical system development, which will dramatically increase our capabilities,”

In addition:

“Our ultimate goal is to print the entire vascular system of a kidney in 12 hours or less.”

Towards a fully 3D printed organ

The kidney has become a significant area of interest in 3D bioprinting research. In particular, much effort has been placed in recreating the winding proximal tubules – the microscopic veins that make the base of a kidney.

3D biomaterial company Organovo recently published a study demonstrating successful binding of kidney cells to make a proximal tubule.

And, at Harvard University, Professor Jennifer Lewis’ lab, led efforts to 3D print a proximal tubule “on-a-chip” that can be used for drug testing.

Though insignificant in comparison to a entirely 3D printed organ, research at this stage is providing the building blocks for future breakthroughs still to come.

A white paper assessing the advances and challenges of tissue engineering have been summarized by Dr. Matheu, and Prellis Biologics’ principle optical engineers Erik Busby and John Borglin here.

Other high speed laser based 3D bioprinting technologies have also been explored before. At the University of California, Los Angeles (UCLA), researchers have developed an SLA based 3D printer that builds multimaterial tissues on a chip.

For medical advances subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Search and post 3D Printing Jobs here.

Featured image shows a microscopic 3D printed structure for encapsulating cells. Image via Prellis Biologics