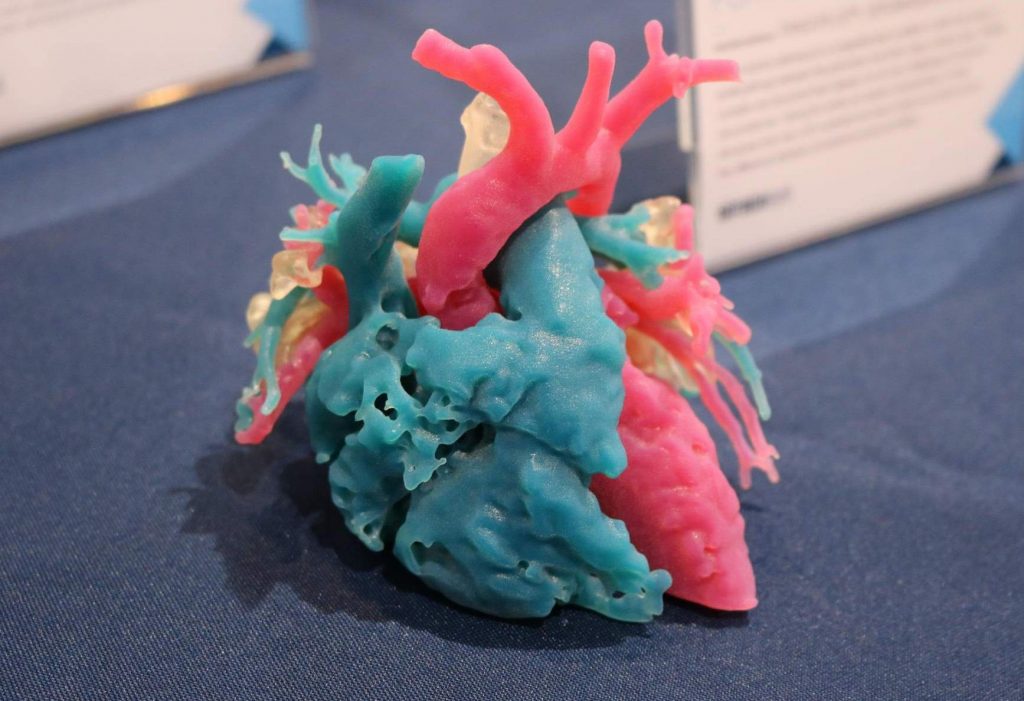

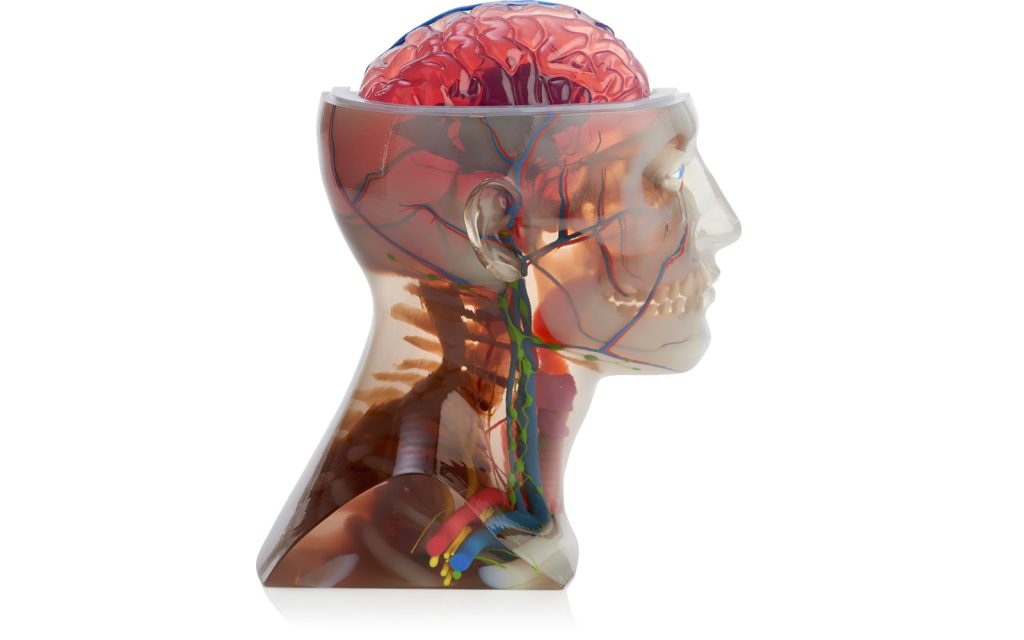

Advancing its 3D printed production of patient-specific anatomical models, Stratasys is expanding its suite of Materialise-validated machines and materials. In a move the company describes as “the most versatile 3D printing system for point-of-care across hospitals and physicians,” new multicolor capabilities will be added to the FDA cleared Mimics inPrint software.

“By validating Stratasys’ 3D printing technologies through our certification process, we’re giving doctors and hospitals improved access to high-quality anatomical models for personalized care to patients,” explains Bryan Crutchfield, Vice President and General Manager of Materialise North America.

“The addition of multi-color and multi-material printers to the list of validated printers is aimed to enable healthcare providers to implement a versatile offering that can support their most complex cases across a wide range of surgical specialties on a single printer.”

Stratasys medical 3D printing

Stratasys has provided medical 3D printing services through its Direct Manufacturing segment for some time. In a conscious effort to increase its medical presence however, the company has been installing its 3D printers in hospitals across the U.S. and improving its ability to create realistic medical aids.

Most recently, Stratasys announced a partnership with New York based 3D printing marketplace Shapeways that had a decidedly medical drive.

Now with Materialise, the J750, J735 and Objet30 Prime 3D printers are validated for use with Mimic inPrint software. A collaboration that could establish both companies as household names for 3D printing in hospitals. According to Materialise, 16 of the top 20 hospitals in the U.S., as ranked by U.S. News & World Report, have implemented Mimics software in practice.

Improving point-of-care treatment

Having demonstrated its potential as a life-changing tool in the operating room, 3D printing’s uptake in healthcare seems to be accelerating, or at least it is an application and use-case for leading industry stakeholders.

By having anatomical models at hand, surgeons and physicians can gain a better understanding of complex conditions. It also creates better communication between the practitioner and the patient. Eyal Miller, Head of Healthcare Business Unit at Stratasys, comments, “Historically, pre-surgical planning relied on 2D imaging requiring physicians to mentally reconstruct the patient anatomy. But 3D printing evolves this approach by putting precise replicas of patient anatomy directly in physician hands,”

“Our collaboration with Materialise is a huge step towards unlocking the potential of this technology for patient care.”

For the latest medical 3D printing news subscribe to the 3D Printing Industry newsletter, find us on Facebook and like us on Twitter. Looking for jobs in healthcare? Search open opportunities and apply with 3D Printing Jobs. You can also make a profile to advertise your latest vacancies.

Featured image shows a full color Stratasys 3D printed samples. Photo via COBRT/PADT