In an agreement with the US Department of Veterans Affairs Center for Innovation (VACI), Israeli 3D printer manufacturer Stratasys (NASDAQ:SSYS) is installing 3D printers in five Veterans Affairs (VA) hospitals around the nation. The 3D printers will be used to help plan surgical operations, train medical students, and produce functional prosthesis for patients in need.

The project is part of Stratasys’ Corporate Social Responsibility that “is aimed at ingraining the power of 3D printing across young minds, bringing transformative medical and educational programs to underprivileged communities, and creating life-changing impacts for the people who need it most.”

From Washington to Massachusetts

The 3D printer of choice is Stratasys’ desktop Mojo model that uses fused filament fabrication (FFF) of layered plastic to create objects. Five of the machines will make it to facilities in Puget Sound, WA, San Antonio, TX, Albuquerque, NM, Orlando, FL, and Boston, MA. The company will also provide the hospitals with relevant training and support to ensure staff make the most of the new technology.

Radiologist Beth Ripley, leader of the VA initiative, comments,

This 3D printing network is a significant step forward in how we approach patient treatments. The technology not only enables 3D models of a patient’s unique anatomy for diagnosis and treatment, but can also be used to engineer personalized health solutions for Veterans – including prostheses and assistive technologies.

“a direct and often immediate effect on societal well-being”

According to Arita Mattsoff, Head of Corporate Social Responsibility at Stratasys,

3D printing is expected to have a direct and often immediate impact on societal well-being – with innovation having the power to dramatically shape lives and communities for the better

Indeed VA certainly recognises this potential. The department’s research and development program in Washington is putting significant effort into understanding the possibilities of 3D printing to help disabled veterans. In collaboration with Human Engineering Research Laboratories (HERL) at the University of Pittsburgh, VA R&D published a paper assessing the utility of 7 different types of additive manufacturing applied to 20 cases of assistive technology.

Democratization of medicine

One of the visions of 3D printing for medicine is that every hospital will eventually be equipped with its own additive manufacturing facility. In November 2016, Australia’s Herston Health Precinct in Brisbane opened a specialist biofabrication institute, alongside existing 3D printing facilities in the area’s Royal Brisbane and Women’s Hospital.

Prostheses is also one area of medicine that has most rapidly accepted the 3D printing as an alternative to the traditional approach. Not only is 3D printing a fraction of the cost of commercially available prosthetic devices, but it means that each model can be tailored made to the specific patient. Some individuals have taken up 3D printing prostheses at home, and charities such as e-Nable and LifEnabled are looking for ways to share the tech with the world.

To stay updated on 3D printed prostheses, sign up to the 3D Printing Industry newsletter and follow our active social media sites.

Vote for innovation now in the first annual 3D Printing Industry Awards.

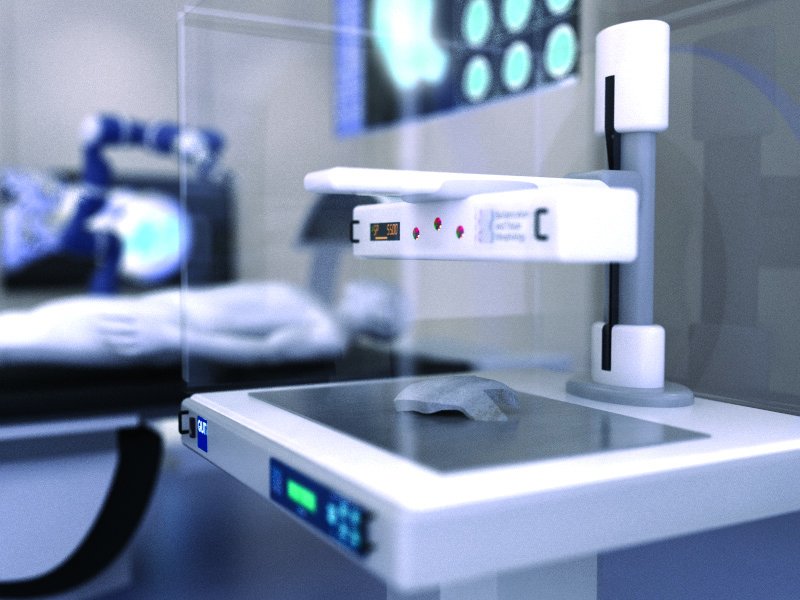

Featured image shows the prosthetic legs of a US Veteran. Photo by Justin Sullivan