When faced with a potentially mortal dilemma perhaps only a brave few would look to 3D printing as a solution, but engineer Tal Golesworthy decided that rather than accept his fate and allow his life to be left in the hands of medical professionals, he would put his faith in a 3D printed model of his own heart.

Marfan syndrome

Tal Golesworthy suffers from Marfan syndrome which affects a number of bodily functions. Simply put, Marfan syndrome is a gene-related issue with a protein known as fibrillin. Fibrillin is vital for elastic fibers such as those in blood vessels. The syndrome particularly affects the heart, and more significantly, the aorta which carries blood away from the heart. The condition can cause the aorta to bulge to alarming levels and can be fatal. Golesworthy had two choices, both reliant on surgery and one which meant removing part of his heart in order to replace it with Dacron, the same material sails are often made from.

This solution would result in a lifelong dependence on anticoagulant drugs. The standard procedure involves removing the weakest section of the aorta along with adjacent valves and replacing it with tubing. This can leave the patient in danger of blood clotting which is why taking anticoagulant drugs is necessary. The blood thinning drugs decrease this risk but create their own problems in the risk of excessive bleeding which could also be fatal.

Golesworthy’s solution

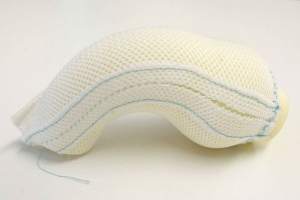

Golesworthy approached his solution with simplicity in mind, rather than replacing the leaky pipe, he wanted to reinforce it by wrapping an object around it. That was the idea and it was through 3D printing that Tal found the means to turn the idea into a reality. He used a CT scanner to map his heart, then with the use of computer-aided design (CAD) and 3D printing he was able to create a 3D model of his heart. Following this, a sleeve using advanced medical polymers was constructed to fit around the model of his aorta, this would later be referred to as a ‘personalized external aortic root support’ (PEARS).

Failure would be fatal

Golesworthy approached this rather deadly predicament with eyes that only an engineer could have, desperate to find an efficient solution. This innovative technique proposed by Golesworthy would have been unsuccessful had it not been for his refusal to fail and this was driven by his natural instinct to survive. The success of this story wasn’t easy either, MRI scanning spanned a total of 30 hours in order to map the aorta for the sleeve printing.

Technology is narrowing the gap between patient and treatment

This sort of case is becoming more and more frequent and it illustrates a change in the relationship between a patient and their treatment. While Golesworthy was never about to attempt performing any such surgery on himself, it’s fair to say he had a huge roll in the treatment he received and this is becoming a trend to take matters into one’s own hands regarding one’s health.

Golesworthy makes this case by saying that his solution, “makes the point that pretty much every patient can make a contribution to the health care system.” In related news 3DPI recently reported on research in China exploring new techniques for 3D printing hearts.

Not just for personal gain

Having needed to create a company for investors to push his invention Golesworthy found he had a good foundation in order to now help others after successfully implanting his printed sleeve into his chest. The company has never been focused solely on money, seeing as survival was Golesworthy’s initial motivation, and this hasn’t completely changed with helping others being at the forefront. Golesworthy’s company is growing in size and the number of patients using his invention is growing by year. Despite this, the process required in order to establish a new procedure like PEARS is not an easy one, particularly when some professionals are not as favorable to these new procedures and their involvement with CAD. Golesworthy isn’t reserved in his critique of surgeons, known for their reluctance to accept new techniques, and this could be seen as the main stumbling block for others to follow suit with their own inventions, like the ExoVasc PEARS device.

3D Printing was the only solution

When faced with a problem of this kind, only CAD and 3D printing could’ve paved the way for Golesworthy’s invention. While Tal was unsure he knew a solution at first, he said that he thought “I’ve got to do something” and it’s no coincidence that Tal turned to 3D printing as his saviour. While perhaps it would take a certain type of individual to boldly propose a solution like Golesworthy’s ExoVasc, it seems only 3D printing could have enabled him to be successful. As previously reported by 3DPI, the use 3D printing to advance science around cardiology was also demonstrated by Harvard researchers.

Featured image shows Golesworthy holding a 3D model of heart. Photo by The Independent

This was previously reported in The Independent.