The world of 3D printed prosthetics is growing and expanding every day. From opensource designs, to bespoke pieces, there is literally something out there for every situation. New York prosthetists Create Orthotics and Prosthetics are launching the first orthotic and prosthetic-specific medical grade 3D printing system to put more control into the hands of prosthetists worldwide. This innovation will allow practitioners to print devices in their own clinics. Based in Lake Placid, Create O&P previously offered personalized leg covers as well as prosthetics that are able to be ordered online. They are also committed to getting prosthetics to people that need them the most.

The system

The system works with Create O&P’s Flexy Fit Prosthetics filament, which is flexible, lightweight and durable. There are also several rigid filaments available through Create.

“We are excited to introduce an easy-to-use 3D printing system that is medical-grade and empowers clinicians to provide the latest in care options to their patients,” said Create O&P CEO Jeff Erenstone, CPO. “I’ve been using this system in my three clinics for the past year and have made my patients very happy with customized devices that fit well and look really great.”

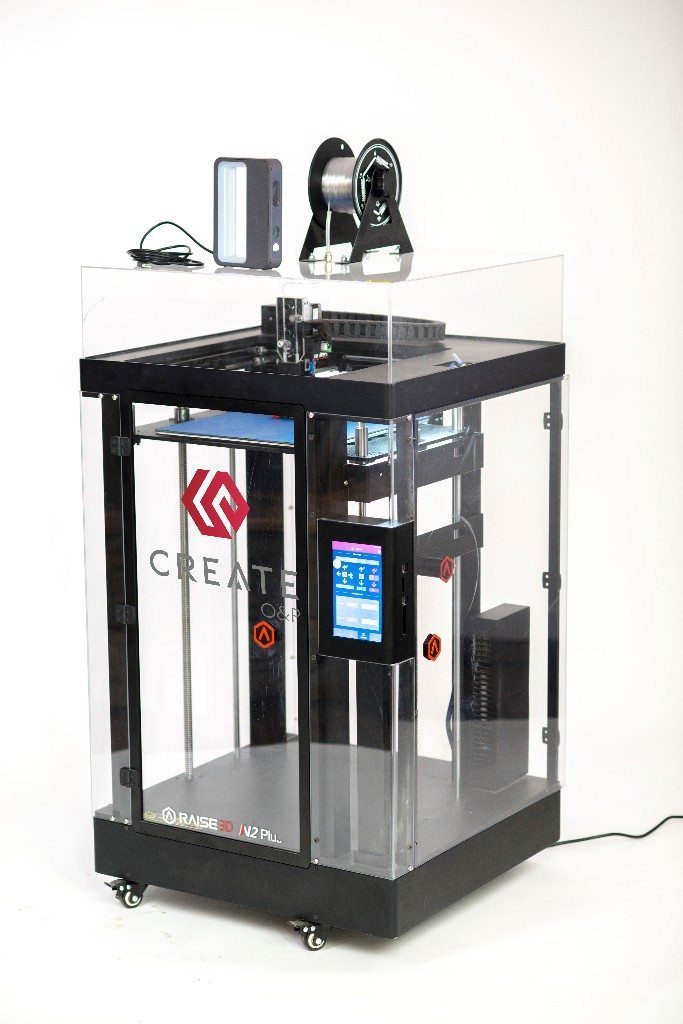

Purchasing the system gives practitioners all the components they need to bring this technology to their clinics:

- 1 professional-grade, 12 x 12 x 24 inch build volume, Create 3D printer, formatted specifically for orthotists and prosthetists

- 3 rolls of medical-grade filament: 1 roll of Create’s FlexyFit blend, 1 roll of PLA filament, and 1 roll of PETG filament

- 1 digital scanner

- 3 months of design services and support

- 1 year of tech support, including printer exchange

The system will allow practitioners to print eight devices all within their own clinics, including flexible inner sockets, diagnostic sockets, leg covers, arms, wrist braces, fingers, models and partial hands.

“Clinicians can design some devices, such as diagnostic sockets or flexible inner sockets, on their own using CAD/CAM, or use Create O&P’s design services to design and code custom devices for their patients,” explained Erenstone. Once Create’s design house has coded each device, it is sent back to the clinician for printing. “Our system cuts about 50% of the time that a clinician typically spends fabricating a similar device. While the print may take several hours or up to a day, the hands-on component of lab time is drastically reduced. It really is plug and play, and we will be there to get you up and running.”

Create O&P estimates that prosthetics produced through its 3D printing system is on average, 65% cheaper than one made via a central fabrication facility.

“We have a few exciting surprises up our sleeve, and we are really looking forward to further increasing practitioners’ capabilities”, Erenstone added. Create plans to roll out additional devices over the next year for clinicians to print using their system.