UPDATE 19/09: We spoke to one of the people behind the project, Hugh McGahern, and he gave us his insight on the machine.

He told us exactly how the junction in the print works, and gave us some pictures as well.

We all love a good Kickstarter, especially one that has new technology to offer the market. British startup Lightning 3D are doing just that, offering their Lightning Double Exposure UV DLP 3D printer on Kickstarter. The early bird offers have gone, but you can still back them and get their printer for £1,600 ($2,100USD).

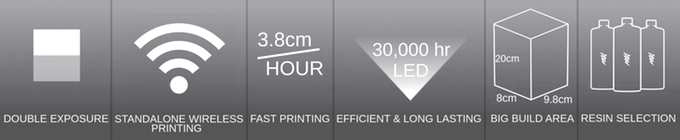

The Lightning offers high performance, double exposure 3D printing. It is a desktop UV DLP 3D printer, and advertises itself as compact, quiet and user friendly. It has wifi connectivity, so you don’t have to tether it to your PC, and can be managed remotely via tablet, phone or laptop.

Double exposure printing

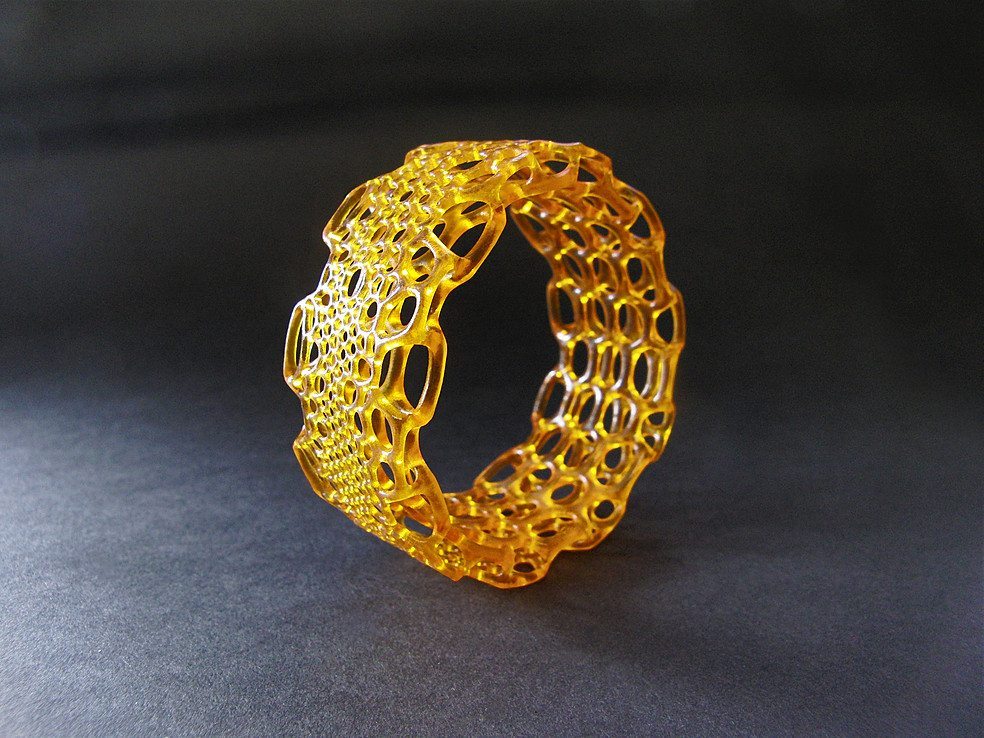

What’s really exciting about this Kickstarter is the innovative double exposure feature. This means that each layer can be exposed in two positions, doubling the available print volume without compromising on the print resolution (xy 62.5 microns/ z 20 microns).

Lightning uses a moving build platform, this allows for each layer to be exposed in two positions, effectively doubling the print volume, this way larger models are effectively formed one half layer at a time, this approach allows for large prints yet retains a very high resolution. When asked about the development of the technology, Hugh McGahern had the following to say.

“Obviously with DLP printers the higher resolution the better, all the 1080p projectors on the market right now are full scale projectors which need a large scale chassis to accommodate them. They also have the downside of using mercury vapour lamps which become an expensive consumable for the printer.

It occurred to me using a 720p ultra portable projector with a UV LED would be much more efficient (the LED would have around 15 times the lifespan of a lamp) and cost effective. If each layer is exposed twice it gives me essentially a full 1080p projection but allows me to build a smaller quieter machine, at the compromise of some print speed.

In the class of modified ultra portable DLP printers there is the Autodesk Ember and Miicraft printers which have high pixel density projection but very modest print areas. Alternatively there is the Moonray printer which has a good size print area but has a pretty low resolution pixel density. The Lightning offers a solution where you can have the smaller quieter machine but retain high resolution printing with a comparatively large print area, in our class we’re pretty aggressively priced and I think better specced in many areas.”

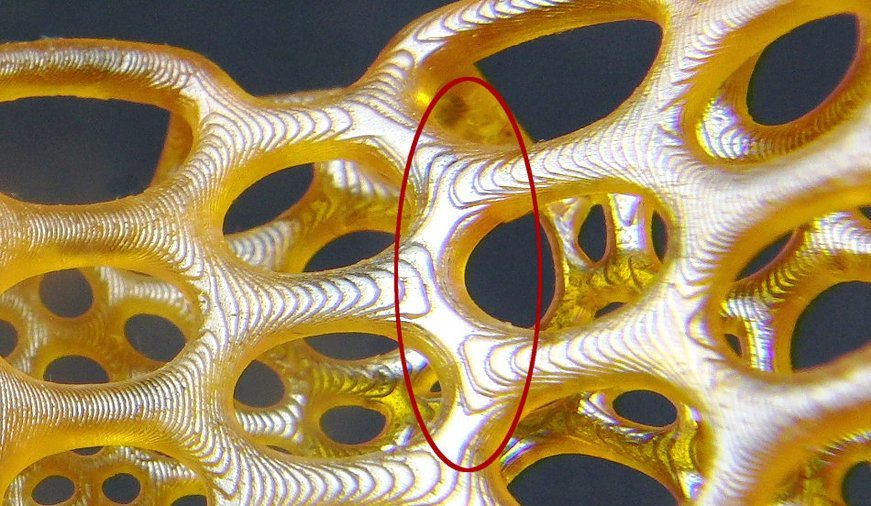

The print junction

“In terms of the junction we tested several different approaches, simply trying to precisely abut the two projections, or using a gradient falloff in an overlap area, or various forms of dithering in the area of cross over, these approaches gave a lower quality finish than simply having an area that is exposed twice in both images.The cross over area is around 2-3mm wide, there is very little appreciable overcuring that’s measurable, on areas where the pixel pattern is visible in the model you can see the same pattern again slightly offset, on a macro scale this isn’t noticeable but if you go looking for it you can find it.”

Light switching

As McGahern said, there are other advantages to this print method. The efficient DLP Light Engine uses a 405nm UV LED as its light source, whereas other projection-based printers often use large projectors. These contain mercury vapor lamps, they produce both visible and UV light and a lot of heat. The DLP Light Engine is more efficient, quieter and cheaper.

“The UV LED in the projector has gone through several design iterations in terms of which technology LED emitters were used, the design and material choice of the MCPCBs that the emitters are on , and finally on the number of small emitters which are arrayed on the MCPCB, the final design is composed of an array 6 small 405nm emitters.”

During the process of SLA printing background light from the projector during the peel cycle can impair the quality of printed parts and cause the resin to gel in unintended places, in extreme circumstances this can lead to damage to the bottom of the resin vat and print failure. Lightning avoids these problems, its LED light source is switched during the peel cycle which is more efficient. This extends the lifespan of the LED and helps to maintain high quality printing during large prints and over the lifespan of the printer.

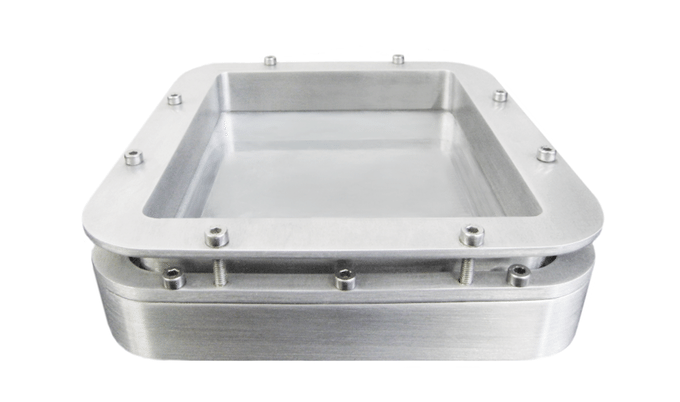

Both the resin vat and the build platform can be quick released via a cam lock and swapped out, allowing you to quickly begin printing a second object while post processing a freshly completed print, or enabling you to switch to a different resin efficiently without having to empty out and clean the vat.

The resin vat utilizes Teflon FEP film, and has a longer lifespan than those made using fragile silicone PDMS. It also doesn’t suffer from clouding issues that silicone vats face, which allows you to focus on your prints.

Resin

Lightning is compatible with a number of third party resins on the market, but a Lightning branded resin is also available in a variety of colors. It is tuned to cure at 405nm, produces hard and durable prints and can easily handle post-processing.

The team is also in the process of prototyping a castable resin, so stay tuned for that.

Software

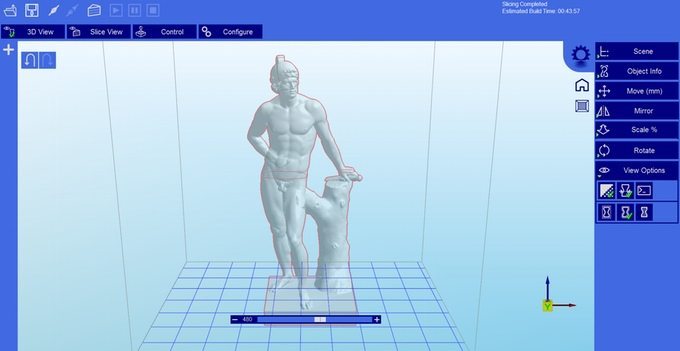

Lightning comes with its own software, Creation Workshop. You can import models here and prepare them for printing. It auto-generates supports for parts, makes it easy to change position and resize your print and can also produce hollow parts. It takes a lot of the work out of printing with a number of preset print settings designed to facilitate flexibility in print speed and quality.

Lightning also has an acrylic anti-UV cover, designed to block UV while still enabling easy monitoring of the print process. It has been designed with maximum access in mind, while also not taking up additional space.

The Kickstarter has 28 days to go (as of September 16), so go and show your support for this awesome new printer.