Since it was unveiled at TED one year ago, the world has been awaiting the release of CLIP 3D printing technology from Carbon in Silicon Valley. In the mean time, the firm has initiating an early customer program, giving companies like Ford and Legacy Effects, Carbon 3D printers ahead of the general public. While you still may not be able to get your hands on the ultra-fast, layerless technology quite yet, you may be able to have parts printed by Carbon 3D printers starting today through four 3D printing service bureaus: CIDEAS, Sculpteo, The Technology House, and WestStar Precision.

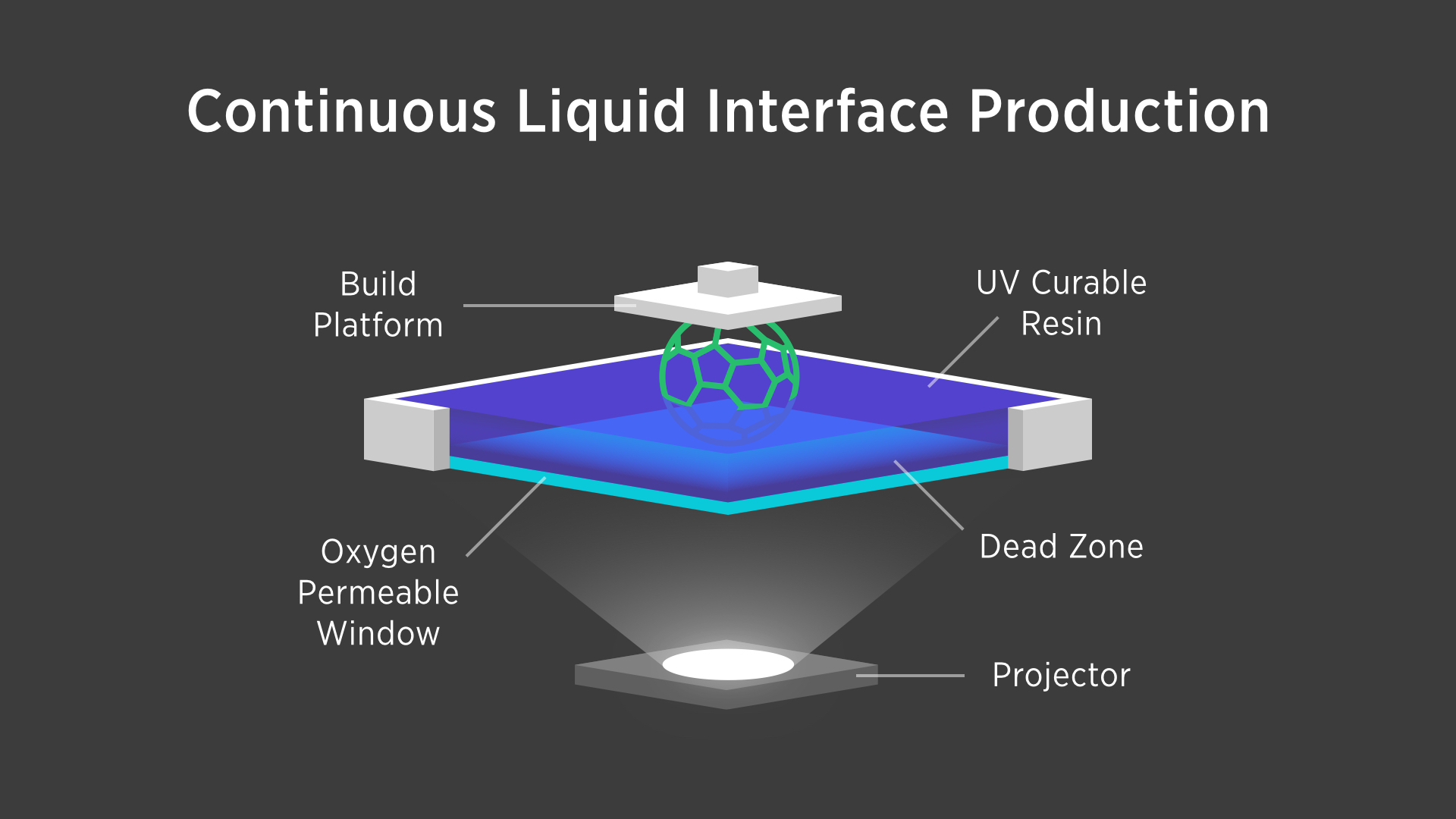

Carbon’s Continuous Liquid Interface Production (CLIP) process works by projecting UV light through an oxygen-permeable, UV-transparent window below a liquid resin. As a print rises through the window, a “dead zone” above the window ensures a continuous print, without visible layers. At the same time, this process allows for printing speeds of 25-100 times faster than other existing technologies, a fact that had the whole world raving about Carbon, including the mainstream media.

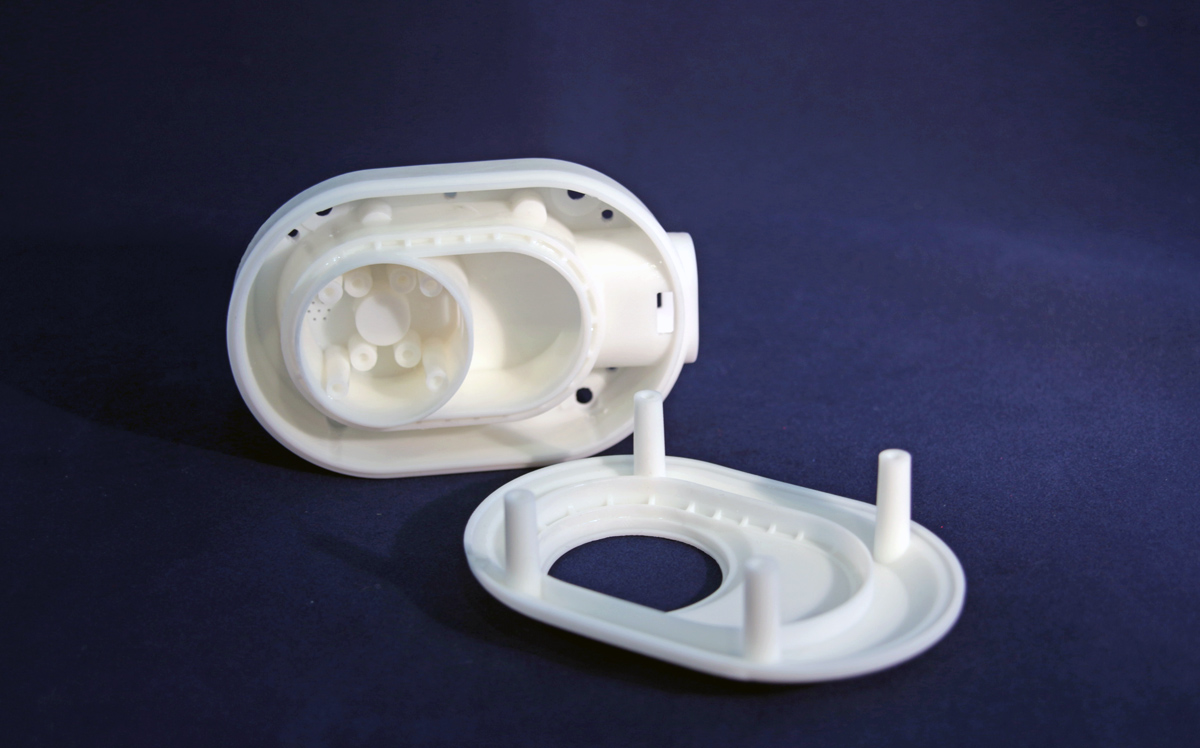

Industry experts, too, were wowed by CLIP because the materials were also described as rivaling those of injection molding, including materials that have elongation and resilience similar to injection molded polyurethane, temperature resistance like glass-filled Nylon, and more. This has led to the Silicon Valley startup obtaining over $100 million from companies like Google and Autodesk and pharmaceutical giant Johnson & Johnson using the firm’s technology to 3D print custom medical devices.

As early customers of Carbon, CIDEAS, Sculpteo, The Technology House, and WestStar Precision will begin offering CLIP 3D printing services to the public for the first time ever. Sculpteo, for instance, will be launching its CLIP printing services at its San Leandro facility in California, where it will use a new range of resins, from rigid to flexible, to 3D print extremely high resolution objects. Clément Moreau, CEO and Co-founder of Sculpteo, says of their new product offering, “This new technology and the revolutionary materials offered are taking 3D printing to a new level. The gap between product design and manufacturing has never been shorter; these speeds are game-changing…”

The combination of high resolution and a wide range of engineering-grade materials will allow designers to take advantage of this technology to create a variety of prototype and production parts, such as load-resistant mechanical parts and flexible gaskets. Mike Littrell, President of CIDEAS, comments, “Carbon’s range of engineering grade materials are a game-changer in advancing what is possible with additive manufacturing. We pride ourselves on partnering with our customers to solve unique challenges and the CLIP-based machine is a powerful tool that helps us create production-quality parts, shorten product development timelines and bring new design concepts to life.”

Joseph DeSimone, CEO and Co-Founder of Carbon, adds, “These new customers are key drivers of innovation and production across industries. We’re excited to partner with them and offer expanded access to CLIP to further uncover application opportunities for our technology.” And, now, thanks to in-house CLIP 3D printing, these service bureaus have some of the most cutting edge additive manufacturing facilities in the world.