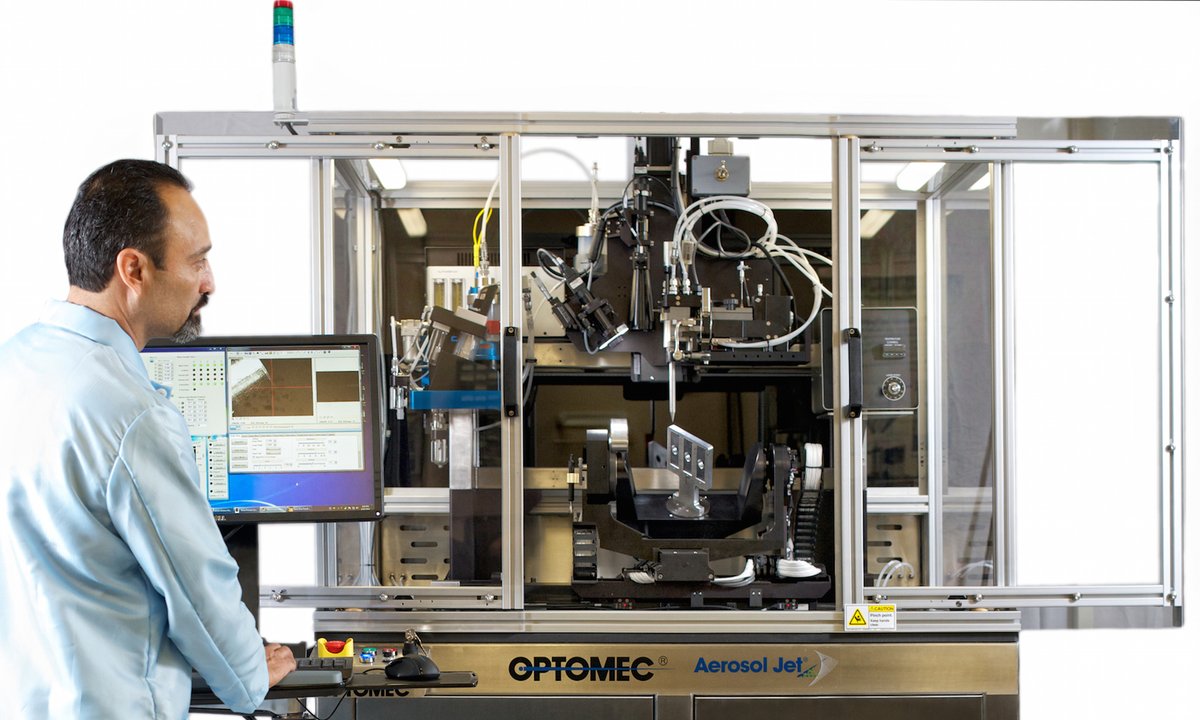

Researchers based in the USA have used Aerosol Jet Printing (AJP) technology from New Mexico-based 3D printer manufacturers Optomec to develop a graphene-based electrochemical sensor for testing food.

According to the study, the sensor is capable of detecting histamines (allergens) and toxins in food much faster than standard laboratory tests. The ability to alter the 3D printing pattern geometry on demand using software control allowed the researchers to rapidly prototype the sensor while optimizing its layout.

Commenting on the findings, which are published today in the IOP Publishing journal 2D Materials, senior author Professor Mark Hersam, from Northwestern University, comments: “We developed an aerosol-jet printable graphene ink to enable efficient exploration of different device designs, which was critical to optimizing the sensor response.”

What is Aerosol Jet Printing?

AJP 3D printing’s early history can be traced to a DARPA-funded MICE (Mesoscale Integrated Conformal Electronics) project in the late 1990s, which aimed to develop manufacturing processes capable of depositing a range of materials onto virtually any substrate.

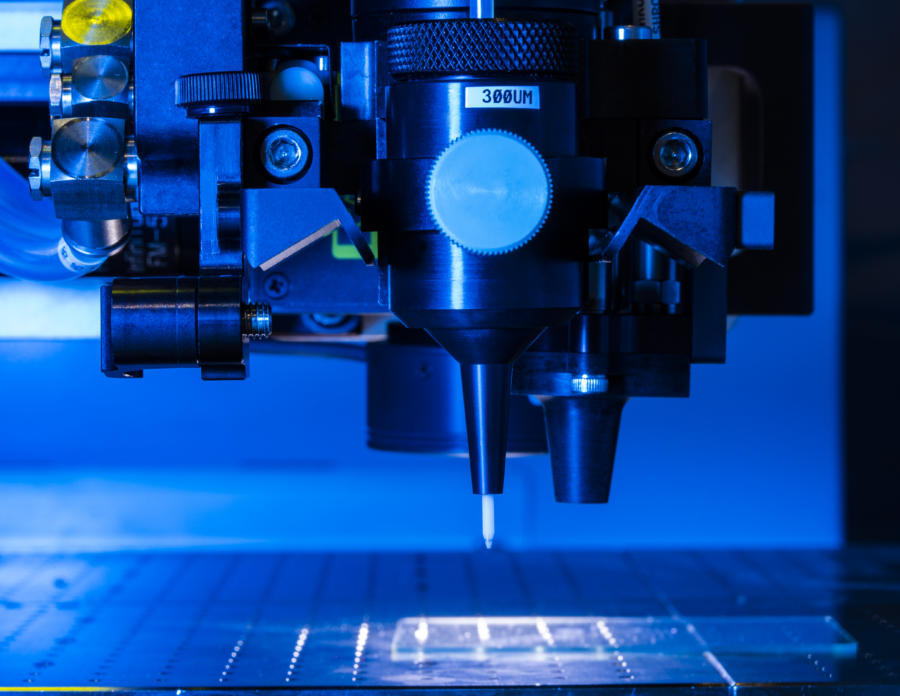

The technology that came out of the project has since been commercialized by Optomec, which develops and provides various AJP systems for applications in 3D printed electronics. AJP is a process suitable for manufacturing electronics on both 2D and 3D substrates. The AJP process forms structures using small ink-like droplets of metals that can adhere to readymade surfaces, enabling multi-material objects to be made. Such a process eliminates the need for wire bonding – for example, printing electrical connections on 3D stacked die or for LED chip fabrication.

Indeed, the researchers explain in the study that “Aerosol jet printing (AJP) offers an alternative high-yield and high-resolution printing technique for device fabrication. This direct-write, additive printing method eliminates the requirement of several fabrication steps and is capable of generating high resolution features without the need of auxiliary patterning.”

AJP technology has been used by various firms to manufacture high-resolution electronic circuits and devices, like strain sensors, wireless Bluetooth transceivers, and small digital-to-analog converter chips. Global defense company Northrop Grumman conducted a study with AJP in 2019, demonstrating the technology as a competent alternative to existing semiconductor technologies. Furthermore, Optomec recently revealed that it had reached the milestone of delivering its 500th 3D printer worldwide. Almost 300 of the install base consisted of AJP systems.

3D printing the electrochemical sensor using graphene and AJP

Despite the multitude of applications for AJP in 3D printed electronics, the researchers explain that “Its application for detecting food allergens such as histamine is yet to be shown,” using electrochemical sensors.

The authors of the study posit that, as AJP only deposits material where it is needed and therefore minimizes waste, AJP sensors are therefore low-cost and straightforward to make, while also remaining portable. These properties could potentially enable applications for AJP 3D printed-sensors in places where continuous on-site monitoring of food samples is needed to determine and maintain the quality of products, as well as other applications. Graphene in particular was identified as a suitable material as it exhibits “unique material properties including high electrical conductivity, surface area, and biocompatibility that have the potential to significantly improve the performance of electrochemical sensors.”

Senior author on the study, Professor Carmen Gomes, from Iowa State University, comments: “Aerosol-jet printing was fundamental to the development of this sensor. Carbon nanomaterials like graphene have unique material properties such as high electrical conductivity, surface area, and biocompatibility that can significantly improve the performance of electrochemical sensors.”

“But, since in-field electrochemical sensors are typically disposable, they need materials that are amenable to low-cost, high-throughput, and scalable manufacturing. Aerosol-jet printing gave us this.”

Therefore, the researchers opted to use Optomec’s AJ200 AJP system to 3D print a graphene-based ink in an interdigitated electrode (IDE) pattern on top of a flexible polyimide substrate. The high-resolution IDE was then converted into histamine sensors by covalently linking monoclonal antibodies to oxygen moieties created on the graphene surface by a CO2 thermal annealing process. The sensors were then tested in both a buffering solution (PBS) and fish broth, to see how effective they were at detecting histamines.

The researchers found that the 3D printed graphene biosensor was capable of detecting histamine in PBS and fish broth over toxicologically-relevant ranges of 6.25 to 100 parts per million (ppm) and 6.25 to 200 ppm, respectively, with similar detection limits of 2.52 ppm and 3.41 ppm, respectively.

Of the figures, co-author Kshama Parate, from Iowa State University explains that “These sensor results are significant, as histamine levels over 50 ppm in fish can cause adverse health effects including severe allergic reactions – for example, scombroid food poisoning. Notably, the sensors also showed a quick response time of 33 minutes, without the need for pre-labelling and pre-treatment of the fish sample. This is a good deal faster than the equivalent laboratory tests.”

Concluding, senior author Dr Jonathan Claussen, from Iowa State University, said: “This type of biosensor could be used in food processing facilities, import and export ports, and supermarkets where continuous on-site monitoring of food samples is needed. This on-site testing will eliminate the need to send food samples for laboratory testing, which requires additional handling steps, increases time and cost to histamine analysis, and consequently increases the risk of foodborne illnesses and food wastage.”

The paper, “Aerosol-jet-printed graphene electrochemical histamine sensors for food safety monitoring,” is published in 2D Materials. Contributing authors include Kshama Parate, Cícero C Pola, Sonal V Rangnekar, Deyny L Mendivelso-Perez, Emily A Smith, Mark C Hersam, Carmen L Gomes, and Jonathan C Claussen.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows fish. Histamine or “Scombroid fish” poisoning is a foodborne illness most commonly caused by consuming certain species of marine fish. Photo via IOP.