Optomec has 3D printed turbine blade sensors for monitoring the performance of GE gas turbines. In addition to this, the company has also announced a strategic alliance with Japanese company Taiyo Nippon Sanso Corporation (TNSC).

The alliance will enable TNSC, and its compressed gas and equipment subsidiary Matheson, to resell Optomec LENS 3D printers. Taiyo Nippon Sanso Corporation is an industrial gas manufacturer and one of the largest suppliers of gas in the world.

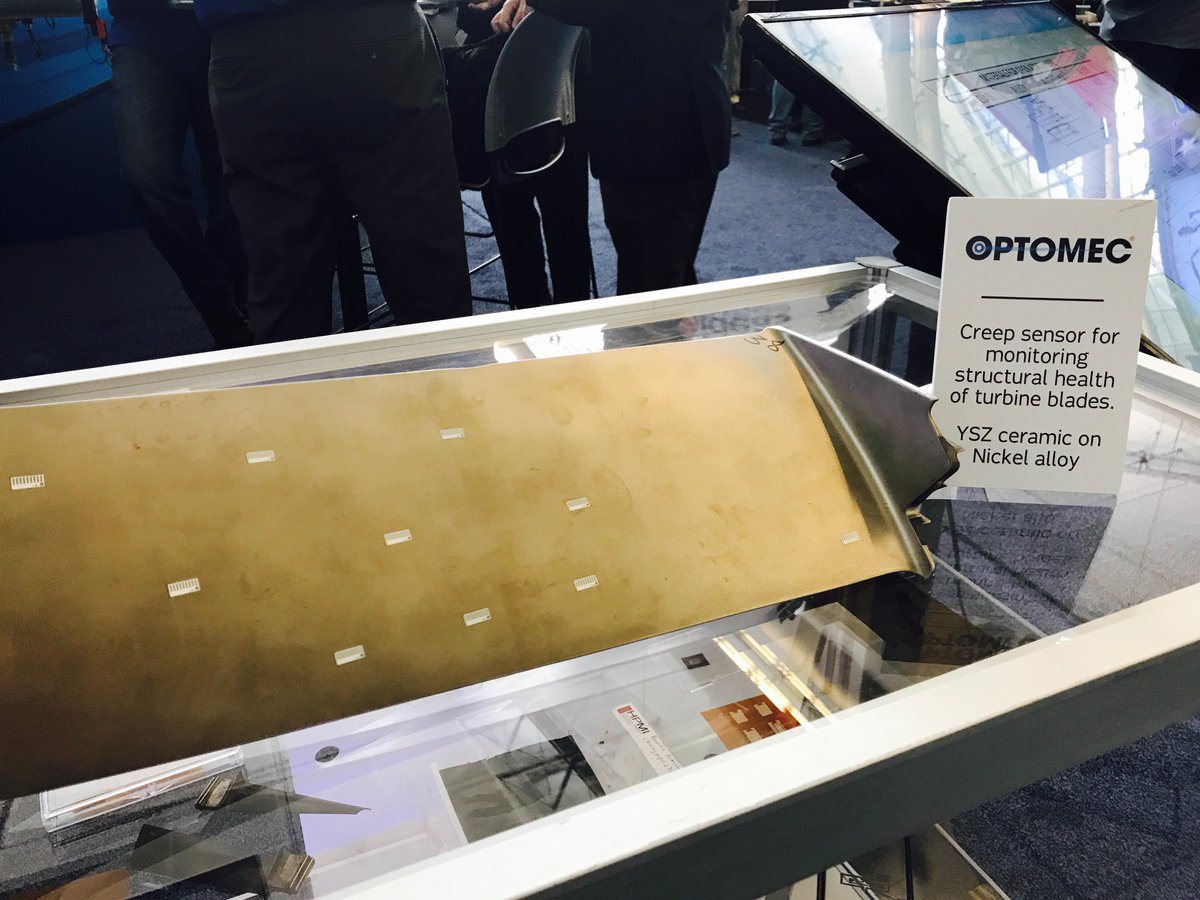

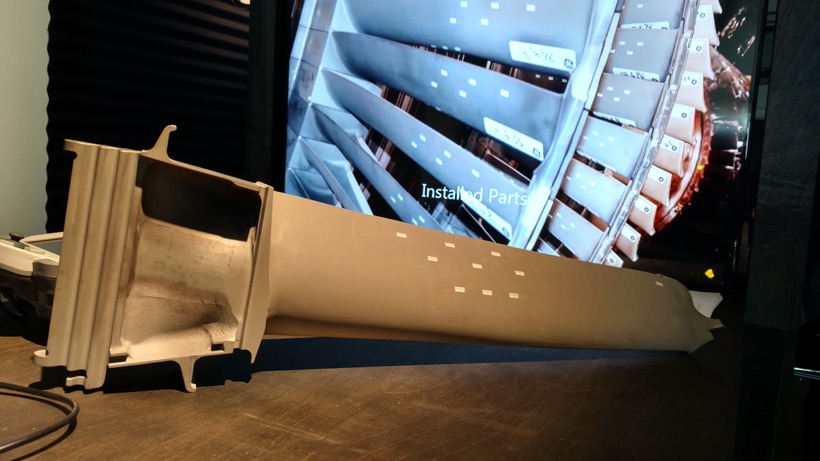

Aerosol jetted stress sensors

Showcased RAPID + TCT 2017, the sensors are produced using a ceramic material designed to withstand the extremely high temperatures found inside a gas turbine. The intention of the sensors is to detect deformities in the underlying metal and prevent turbine failure which could be both expensive and devastating.

Optomec’s Aerosol Jet Technology, a method of spraying electronic inks on to a substrate, was used to print the passive strain sensors directly onto the blades. This technique has also been recently expanded by the company to utilize copper inks, broadening its applications for 3D printed electronics.

According to Optomec the data from the printed sensors can be integrated into GE’s Predix digital software platform. Predix is GE’s digital industrial platform that intends to connect industrial equipment and analyze data to deliver real-time insights.

In addition to these sensors, GE has been incorporating additive manufacturing in the production of turbine blades for the GE9X aircraft engine.

TNSC’s total additive manufacturing solution

With Optomec LENS technology, TNSC and Matheson now have a “total AM solution offering” for customers including all the materials, gases and subsequent equipment needed to manufacture and process metal. The strategic alliance between the two companies has also been supported by an unspecified capital contribution from TNSC, and sees the launch of a dedicated research and development team at the TNSC lab in Yamanashi, Japan.

In 3D Printing Industry’s first look at the latest technologies at RAPID + TCT, we have also seen Optomec’s new LENS 3D Hybrid Machine Tool, that the company regards as an “industry first hybrid controlled atmosphere system.”

For more of the the latest 3D printing news direct to your inbox subscribe to our newsletter. You can also follow our live feed on twitter.

The 3D Printing Industry Awards will be taking place this month in London, so make sure to place your votes to decide the winners.

Featured image shows Gas Turbine Compressor Blades. Photo via Flickr user fotografiacole.