Researchers from the University of Technology Sydney (UTS) and Deakin University in Australia, have used 3D printing to create meals that are designed to be tastier and safer to eat for people with swallowing disorders (dysphagia).

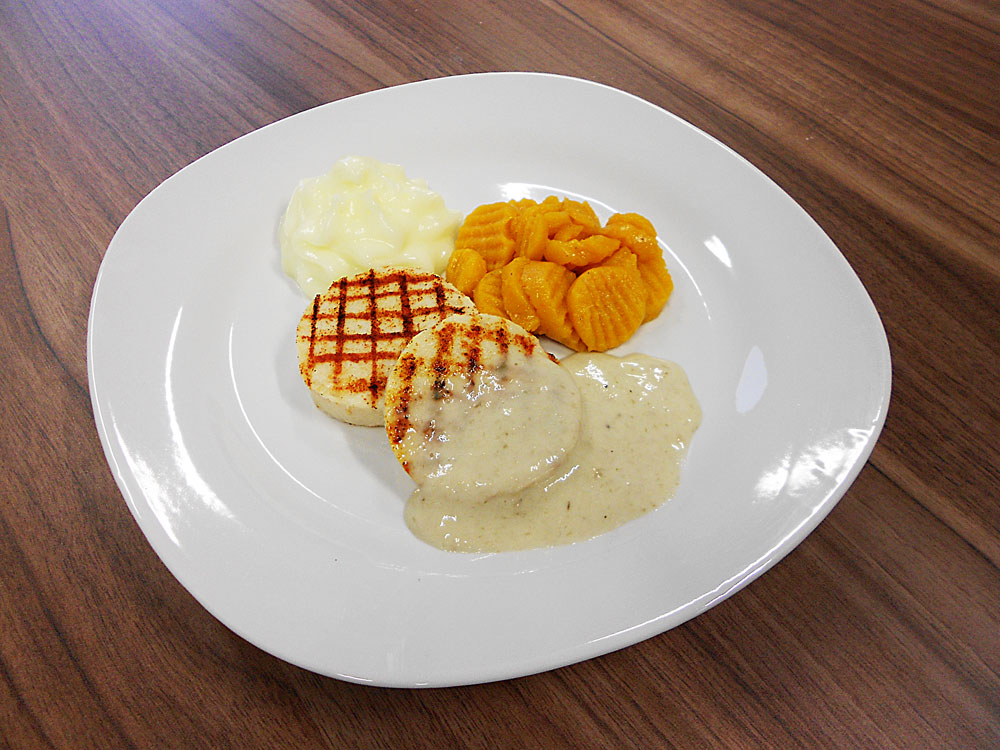

Using pureed food as ‘ink,’ the research team 3D printed foods in a way that would make them more visibly appealing, and safer to eat for those with dysphagia. Given that many social activities are based around eating out, the researchers suggested that the advantages of the 3D printing technique could go beyond simply adding nutritional value.

“People with swallowing disorders often face the danger of choking on food, which can be fatal. So to make food easier to eat, some people need it to be soft, or even pureed, at which point the look and feel of the food can change, affecting the person’s appetite and quality of life,” said speech pathologist researcher Professor Bronwyn Hemsley.

“If it [3D printed food] is going to print in any shape, they could go to a Christmas party or a birthday party and still be part of the special occasion. They could still eat things that look like cake, nuts or biscuits, but are made of a puree texture”, she said.

3D printed food and swallowing disorders

Approximately eight percent of Australians (two million people), suffer from dysphagia associated with stroke, Parkinson’s disease, motor neurone disease or dementia, according to Professor Hemsley. The disorder can have severe repercussions, potentially leading to aspiration pneumonia, malnutrition or even choking. Swallowing disorders are often managed by those that suffer from them by adopting modified diets, but these can be unappetizing, and affect their quality of life.

3D printing has been utilized in the past to combat dysphagia, with German food innovations company Biozoon launching its 3D printed food extruder in 2014. Nonetheless, according to the Australian researchers, continued development is necessary to develop a wider range of 3D printed natural and nutritious foods, including those containing proteins and fats. In addition, there remains a need to devise a large-scale method of 3D printing foodstuffs, that can be individually-tailored for people with special nutritional requirements.

For 3D printed food to be adopted on a larger scale, the researchers identified that a more systematic approach was needed, and set out to identify the problems and solutions around providing foods for people with specific dietary needs. Having cross-referenced studies between 2012 and 2017 regarding this application of 3D printed foods, the research team found no scientific evidence that these meals provided improved nutritional value. As a result, the Australian researchers’ goal of creating 3D printed food with greater nutrition remained an aspirational one, and they launched a review of all related 3D printing studies.

Peer-reviewed additive food studies

Having analysed existing studies, the Australian team found that initial research went into making 3D printed food more appealing, producing chocolates, sugars and cookies. Consequently the design and creation of a range of nutritious food continues to be problematic, with some commercially-available products maintaining this approach. In order to change this, and produce healthier meals, the researchers cited a report by the University of Queensland in 2016. The study identified foods produced using liquid-based deposition techniques as being better suited to producing foods with a high nutritional value. While this approach yielded moderate successes, high molecular weight polymeric carbohydrates still proved difficult to print without modification.

In order to make 3D printed food appear more appealing than conventional food substitutes, another study by Kansas State University used food molds to shape the foodstuff into more appetising shapes. The results of this research didn’t reflect well on these molded meals though, with many elderly trialists finding them more difficult to swallow. Nonetheless, the Australian scientists maintained that there was no recorded study of 3D printed foods being used in care homes, and set about making nutritious ‘soft foods’ for applications with the elderly.

The Australian researchers’ findings

Using a 3D food printer installed at UTS’ Protospace Lab, the researchers used real pureed food as the ink, and the compressed meal was fully cooked before the printing process started. The 3D printer’s cartridges were then filled with the liquified food, before it was printed into a pre-programmed 3D shape. According to Professor Hemsley, the social implications of the technology could be as significant as the nutritional benefits.

“From what we know of 3D food printing so far, it’s a creative and fun activity. Often people are surprised and express joy in what they’ve made. But they can also be disappointed if the shape isn’t as good as they expected, or looks worse than their familiar foods,” said Hemsley.

“We don’t know yet whether people with swallowing disabilities would want to take part in 3D food printing, the support they’d need, whether they’d use it, and what benefits they expect. We need to know this, and also to find ways that we can make 3D printing more accessible to more people, if it’s going to help to improve their lives,” she said.

The researchers concluded that further observational studies were needed, in order to ascertain what the remaining barriers to the widespread adoption of the technology by the elderly could be. Moreover, greater control needed to be put in the hands of consumers during these projects, to better optimize 3D printed foods for use in residential settings. According to the research team, consumer-friendly 3D printers, with pre-set CAD files for meals with specific visual appearances, could be the future of the technology, but only with a renewed user-focus.

3D printing in the food industry

A number of 3D printing companies have scaled up their preparation for the mass manufacturing of food products in recent years.

Israeli food 3D printing start-up, Redefine Meat raised $6 million in a seed funding round, to advance the development of its alternative-meat 3D printer in November 2019. The company’s goal was not simply to create a new food product, but to design a novel production process.

Campden BRI, a food and drink research organization based in the UK, conducted a study examining the capabilities of 3D printing technology with various types of food material in April 2019. The company aimed to develop its own 3D printing capabilities based on the analysis.

Scientists from Columbia University developed a new method to 3D print cooked food in April 2019. The 3D printing method was unique because it could combine different ingredients, such as chicken with dough, and cook each ingredient selectively.

The researchers’ findings are detailed in their paper titled “Review Informing the Design of 3D Food Printing for People with Swallowing Disorders: Constructive, Conceptual, and Empirical Problems”. The study was co-authored by Bronwyn Hemsley, Stuart Palmer, Abbas Kouzani, Scott Adams and Susan Balandin.

You can now nominate for the 2020 3D Printing Industry Awards. Cast your vote to help decide this year’s winners.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the experimental meals being prepared at UTS’ Protospace Lab. Photo via UTS.