Researchers from the University of Witwatersrand have assessed the challenges of using hydrogel-based bio-inks for 3D printing tissues, and made recommendations to enhance the applications of the technology.

The scientists found that although it’s safe and efficiable to 3D print tissues, bioprinting has limitations based on the cost, integrity, and strength of biomaterials used in the process. According to the research team, only the development of a novel bio-ink will enable the larger-scale production and adoption of multicellular and multimaterial bioprinting.

The increasing adoption of 3D bioprinting

3D bioprinting has often been applied to address incidences of donor scarcity and organ shortages. The 3D printing process reduces immunogenicity, because hydrogel-based bio-ink is patient-specific, and this leads to a decrease in organ rejection and an enhanced supply in accordance to demand. What’s more, the bio-inks used to create such tissues are based on hydrogel frameworks such as alginate, which offer lower toxicity and costs, and display an increased biocompatibility.

While bioprinting encompasses a variety of methods such as Selective Laser Sintering (SLS), extrusion, and inkjet bioprinting, each method has several advantages over conventional tissue seeding for tissue engineering. 3D bioprinting for instance, can be used to create biomimetic structures based on a 3D scan from a patient’s damaged or injured body organ, allowing for the production of a patient-specific structure.

In traditional methods meanwhile, the placement of cells involves implanting them into a scaffold of chemical growth hormones, which are required for the growth and development of cells for tissue engineering. This is followed by in vivo implantation using a polymer such as Polyglycolic acid (PGA), due to its thermoplastic and biodegradability. There are many drawbacks to this approach, including a lengthy timescale, its inability to produce vascular structures, and the limitations of the PGA material used.

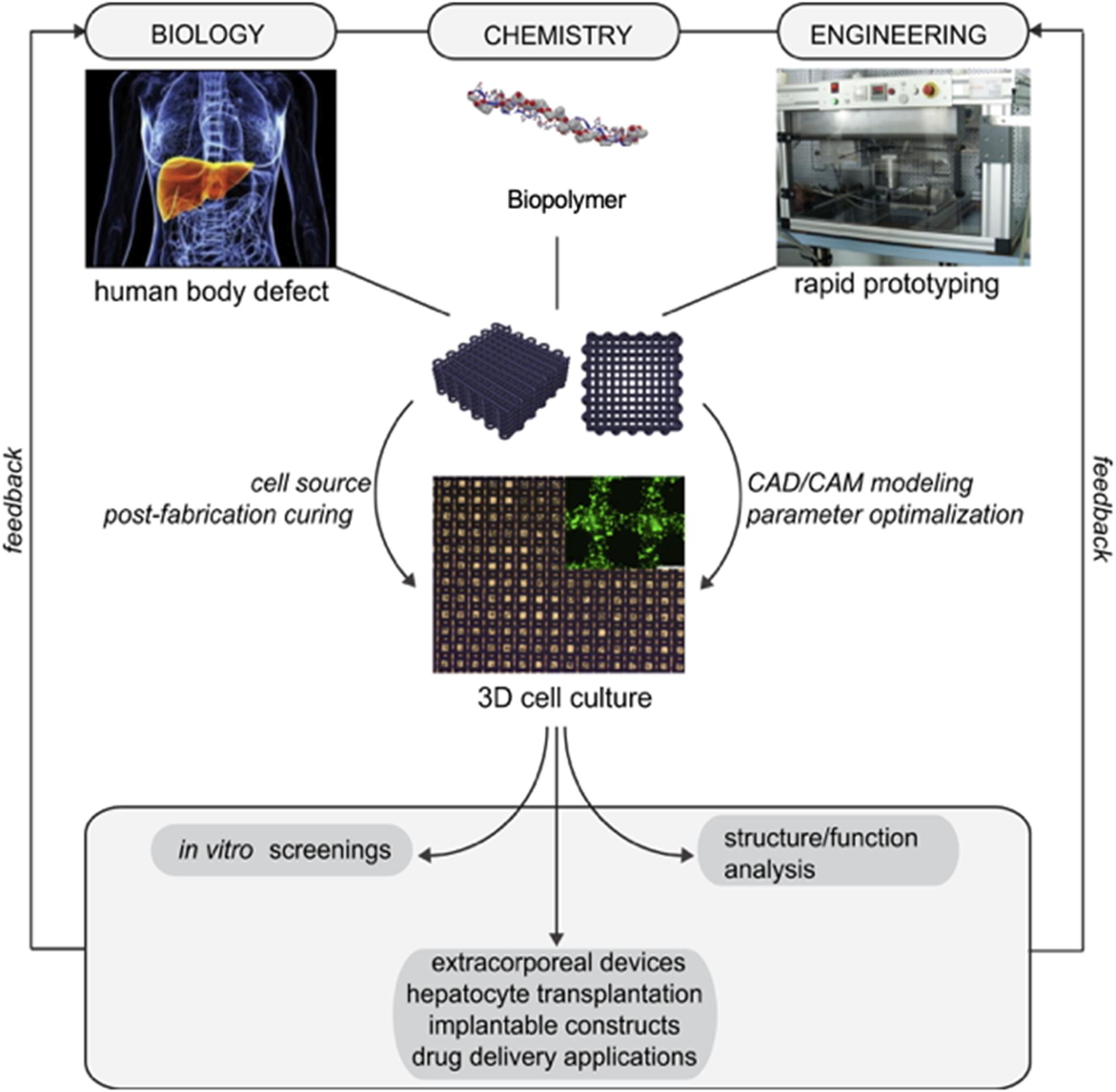

3D bioprinting overcomes many of these issues, by using a CAD model to develop a 3D organization of living cells within a temporary biodegradable scaffold. This allows for the simultaneous dispensing of biomaterials and cells, resulting in seeding efficiency and the prevention of non-homogenous cell distribution because of postfabrication seeding. The researchers aimed to assess the advantages and limitations of different 3D tissue engineering techniques, and recommend areas where they can be improved upon.

The researchers’ assessment of 3D bioprinting

Assessing the hydrogels that are commonly used to create cell-laden structures within the 3D bioprinting process, the researchers praised their flexibility. The soft materials can be engineered to mimic the extracellular tissue microenvironment, enabling their medical application as biosensors, scaffolds for tissue regeneration, and drug delivery technology. Nonetheless, the researchers also highlighted limitations to certain hydrogels that can induce various side effects stimulated by polymerization residues. The erosion and degradation of the polymer network over time, can result in cellular death, central nervous system damage, and skin or ocular irritation.

The researchers suggest that using a reversible-deactivation radical polymerization technique, which periodically attaches and detaches active molecules or residues, could prevent the undesirable outcomes produced during polymerization. Moreover, according to the research team, during the extraction procedure, cell temperature, oxygen, carbon dioxide, and pH levels are often ignored, and this is essential to their viability. Citing a lack of research into effects of cells on the rheological behavior of bio-inks, the research team added that increasing cell density often leads to a decrease in the crosslinking ability.

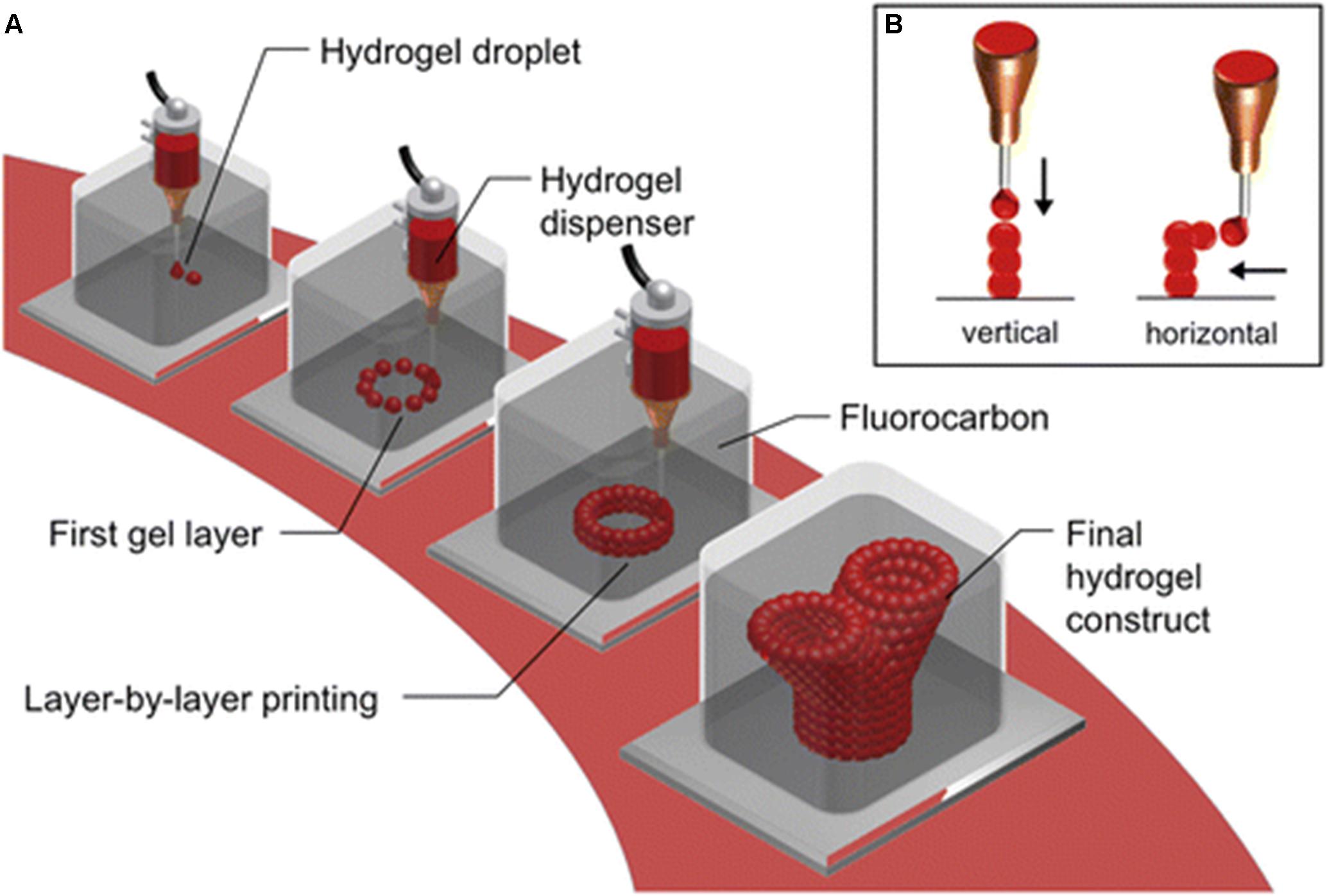

Another issue raised by the South African researchers was the need for a new bio-ink that maintains a low viscosity, while bearing a consistency that allows for the formation of a solid or semisolid structure postprinting. This intermediate thickness demonstrates significant challenges, and impedes upon the suitability and feasibility of the process for large-scale manufacturing. Printing in high-density perfluorocarbon (PFC) fluid, was found to be a superior method when compared to the commonly used method of printing from a medium of air. The hydrogel droplets printed submerged in PFC, exhibited an increased contact angle, decreased flatness, and reduced diameter as compared to printing in an air medium.

Cross-linking was also demonstrated to be effective, and the introduction of a 10% wt/vol of CaCl2 via aerosol dispensing, showed an enhancement in the viscosity of an alginate solution used as a hydrogel-based bio-ink. This resulted in a hydrogel alginate bio-ink that demonstrated significantly improved mechanical strength, and ability to support cellular activities. Nonetheless, photocrosslinking also includes the exposure of ultraviolet (UV) light radiation to biological entities, and this can generate cytotoxic free radicals and stimulate local inflammation.

The researchers concluded that the selection of material deployed in 3D bioprinting is vital to the successful creation of 3D printed tissues. Current biomaterials used in 3D printing are limited to alginate, cellulose, gelatin, polyacrylates, and hyaluronic acid, and the research team suggested that a novel bio-ink will ultimately need to be developed. This material will need to be capable of fabricating multifunctional structures with appropriate mechanical strength, in order to support cellular viability and printability. According to the South African researchers, its creation will require a multidisciplinary approach, that consists of practicing clinical surgeons and pharmacists, and is not just limited to research scientists.

Using 3D printing to create biological tissues

A range of biomaterials have been devised in recent years, in order to enable the fabrication of 3D bioprinted tissues.

Researchers from the University of Colorado Denver and the Southern University of Science and Technology in China for instance, created a novel 3D printing material that’s able to imitate the behaviours of biological tissues. When the honey-like Liquid Crystal Elastomer (LCE) resin is hit with UV light, it cures, and forms new bonds in a succession of thin photopolymer layers.

Scientists from the Department of Biomedical Engineering at Texas A&M University, have created a highly 3D printable bio-ink. The biomaterial can be used as a platform for generating anatomical-scale functional tissues, and has been designed to overcome the structural deficiencies of current bio-inks.

New Jersey-based Rutgers University engineers have developed a novel bio-ink, which consists of living cells, and can be used to 3D print scaffolds for human tissue growth. The researchers were able to precisely control the material’s properties using various mixing techniques.

The researchers’ findings are detailed in their paper titled “Hydrogel-Based Bioinks for 3D Bioprinting in Tissue Regeneration” published in the Frontiers in Materials journal on April 30th 2020. The study was co-authored by Previn Ramiah, Lisa C. du Toit, Yahya E. Choonara, Pierre P. D. Kondiah and Viness Pillay.

You can now nominate for the 2020 3D Printing Industry Awards. Cast your vote to help decide this year’s winners.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the submerged bioprinting technique, one of those assessed by the Witwatersrand research team. Image via Frontiers in Materials.