Scientists in the Department of Biomedical Engineering at Texas A&M University are seeking to advance the field of 3D bioprinting functional tissues, by conducting research into the development of new biomaterials.

Dr. Akhilesh K. Gaharwar, an associate professor in the department, has created a highly 3D printable bioink, which can be used as a platform for generating anatomical-scale functional tissues. The new material developed by Gaharwar’s research group, known as Nanoengineered Ionic–Covalent Entanglement (NICE) bioink, has been designed to overcome the deficiencies of current bioinks in relation to structural stability. Commenting on the benefits of the NICE bioink, Gaharwar states: “The next milestone in 3D bioprinting is the maturation of bioprinted constructs toward the generation of functional tissues.”

“Our study demonstrates that NICE bioink developed in our lab can be used to engineer 3D-functional bone tissues.”

Bioprinting bone tissue

In their study, Gaharwar’s research group first outlined the emergence of 3D bioprinting as a technique for fabricating patient-specific, implantable constructs for regenerative medicine. Using hydrogels and combining them with cells and growth factors, these bioinks are 3D printed to create tissue-like structures intended to imitate the function of natural tissues.

One particularly useful application of the technology is in patient-specific bone grafting, a surgical procedure that replaces missing bone in order to repair bone fractures. As traditional treatments for managing bone defects and injuries are slow and expensive, Gaharwar states that developing replacement bone tissues with bioprinting could create exciting new treatments for patients. These can be used to treat defects and conditions such as arthritis, bone fractures, dental infections and craniofacial defects.

Recent advancements in the field have come from Rice University and the University of Maryland (UMD). Scientists at these institutions have outlined a new proof-of-concept for 3D printing artificial bone tissue to help repair damage related to arthritis and sporting accidents.

In late 2019 onboard the ISS, 3D Bioprinting Solutions, a Russian bio-technical research laboratory, 3D bioprinted bone tissue in zero gravity. Leveraging its Organ.Aut 3D bioprinter, the lab’s researchers hope to one day create real bone implants for astronaut transplantation on long interplanetary missions.

Nanoengineered bioinks for stronger bone structures

In the bioprinting process, cell-laden biomaterials flow through a nozzle in liquid form, however immediately solidify as soon as they’re deposited. It is necessary for bioinks to act as cell carriers and structural components, which requires them to be highly printable while providing a robust and cell‐friendly microenvironment.

As outlined in the research paper, Gaharwar’s team explain that current bioinks in use lack the sufficient biocompatibility, printability, structural stability and tissue‐specific functions needed for preclinical and clinical applications of bioprinting. “The potential applications of bioprinting have been limited due to the lack of bioinks capable of meeting the demands of both 3D printing and tissue engineering. For example, ideal bioinks must be capable of extruding into stable 3D structures, while also protecting cells during and after printing, and providing an appropriate environment that can be remodeled into the target tissue. Unfortunately, conventional hydrogels are weak and poorly printable,” explain the authors.

In response to this issue, Gaharwar’s research group has developed the NICE bioink formulation specifically for 3D bone bioprinting. NICE bioinks are a combination of two reinforcement techniques (nonreinforcement and ionic-covalent network). Used together, they provide an effective reinforcement that results in much stronger bone structures. Explaining the benefits of the material, the researchers write: “The NICE bioinks allow precise control over printability, mechanical properties and degradation characteristics, enabling custom 3D fabrication of mechanically resilient, cellularized structures.”

Once the bioprinting process is complete, the cell-laden NICE networks are crosslinked to form stronger scaffolds. Using this technique, Gaharwar and his team have been able to produce full-scale, cell-friendly reconstructions of human body parts, including ears, blood vessels, cartilage and bone segments.

In their tests, the researchers found that the enclosed cells began depositing new proteins containing a cartilage-like extracellular matrix that subsequently calcifies to create a mineralized bone over a three-month period. Five percent of these 3D bioprinted scaffolds consisted of calcium, which is similar to cancellous bone, the network of spongy tissue typically found in vertebral bones.

Gaharwar’s research group used a genomics technique called whole transcriptome sequencing (RNA-seq) to examine how these bioprinted structures were able to induce stem cell differentiation. RNA-seq works by capturing a snapshot of all genetic communication inside the cell at a given moment. The team worked with Dr. Irtisha Singh, assistant professor at the Texas A&M Health Science Center, who served as a co-investigator.

Using their bioink and research results, Gaharwar’s team plans to demonstrate in vivo functionality of the 3D bioprinted bone tissue.

The study, “Nanoengineered Osteoinductive Bioink for 3D Bioprinting Bone Tissue” is published in ACS Applied Materials & Interfaces. It is written by David Chimene, Logan Miller, Lauren M. Cross, Manish K. Jaiswal, Irtisha Singh, and Akhilesh K. Gaharwar.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

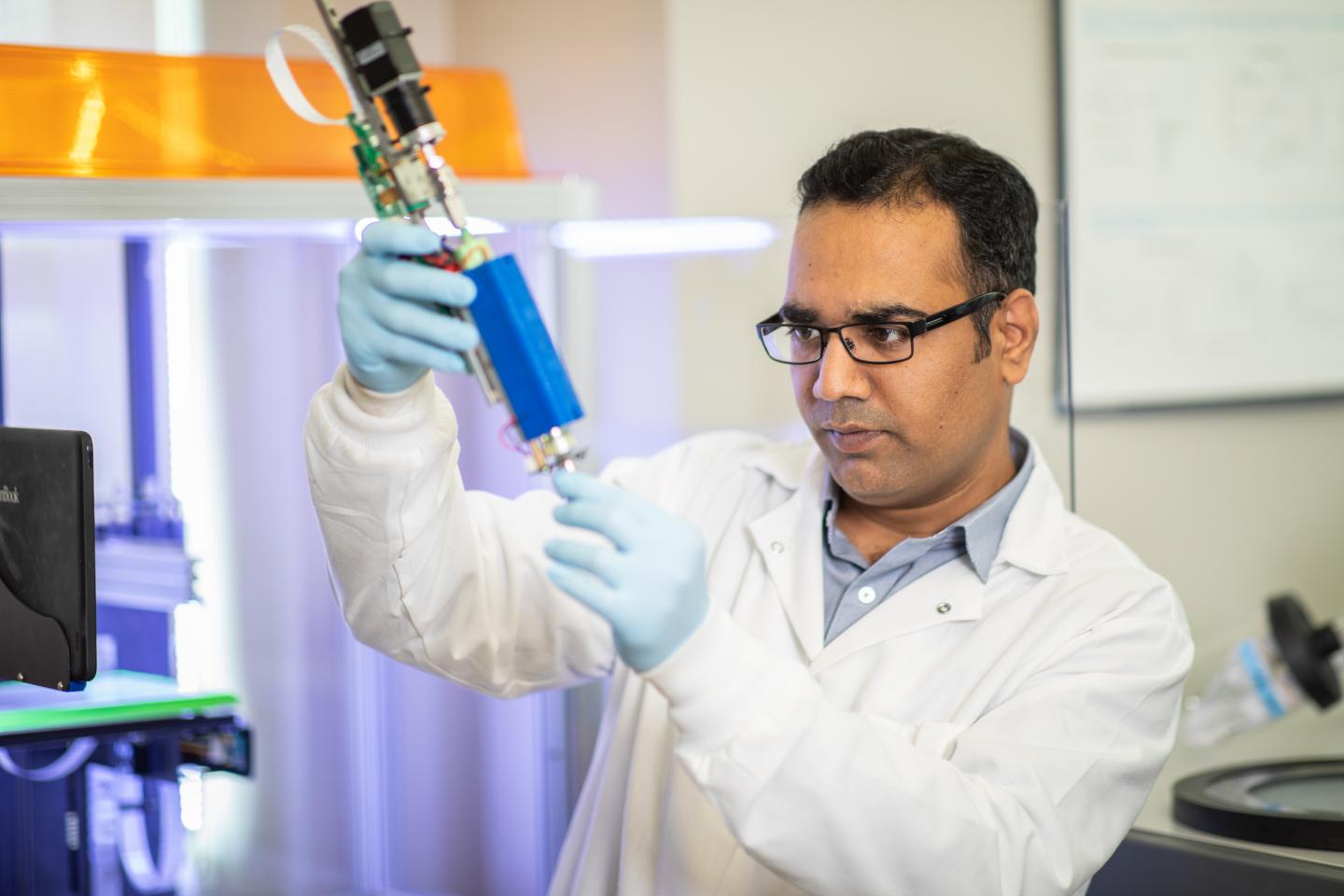

Featured image shows Dr. Akhilesh Gaharwar. Photo via Texas A&M Engineering.