Researchers at Texas A&M University, in collaboration with scientists at Texas-based 3D printer manufacturer Essentium, have developed a method to more effectively weld adjacent layers together in a 3D printed part.

The group of researchers explain that a “weak spot” of 3D printing lies in the imperfect bonding between the individual printed layers that make up components. This can result in 3D printed plastic parts – from simple toys to custom prosthetic parts – that are mechanically weak.

In order to overcome this problem, scientists at Texas A&M and Essentium have integrated plasma science and carbon nanotube technology into standard 3D printing in order to weld adjacent printed layers more effectively. The results are 3D printed parts with increased reliability.

“Finding a way to remedy the inadequate bonding between printed layers has been an ongoing quest in the 3D printing field,” explains Micah Green, associate professor in the Artie McFerrin Department of Chemical Engineering.

“We have now developed a sophisticated technology that can bolster welding between these layers all while printing the 3D part.”

Improving the layer fusion process

Plastic materials are commonly used in the FDM process, an extrusion-based 3D printing technique. FDM 3D printing involves molten plastic that is squeezed out of a nozzle to 3D print parts layer by layer. When the layers cool down, they fuse together to form the final 3D printed component.

The researchers explain how numerous studies have demonstrated that layers in the FDM process are joined together imperfectly. This results in 3D printed parts that are weaker than identical parts made by injection molding where melted plastics simply assume the shape of a preset mold upon cooling.

To improve the layer fusion process, the team of scientists explain that additional heating is required. However, when heating 3D printed parts in an oven-like chamber, there are significant negative consequences: “If you put something in an oven, it’s going to heat everything, so a 3D printed part can warp and melt, losing its shape,” Green said. “What we really needed was some way to heat only the interfaces between printed layers and not the whole part.”

Focused on facilitating inter-layer bonding, the team opted to leverage carbon nanotubes and electricity. As carbon particles heat up in response to electrical currents, the researchers coated the surface of each printed layer with the nanomaterials. The team found that the carbon nanotube coatings could be heated using electric currents, enabling the 3D printed layers to bond together effectively.

In order to apply electricity to objects as they are 3D printed, the currents must overcome a tiny space of air between the printhead and the 3D part. One method of bridging that air gap involves the use of metal electrodes that are in direct contact with the 3D printed part, however Green states that this can introduce inadvertent damage to the part.

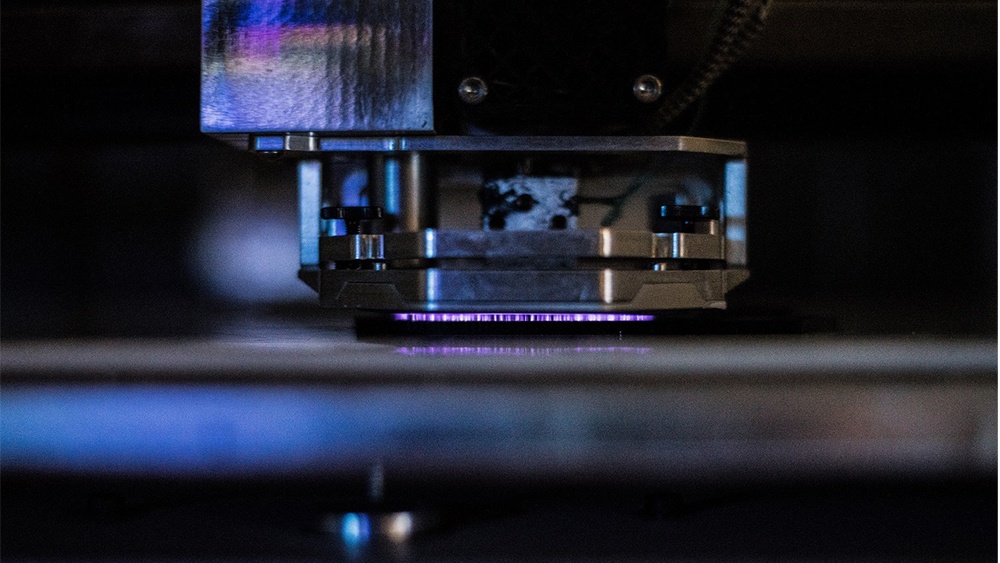

Collaborating with David Staack, associate professor in the J. Mike Walker ‘66 Department of Mechanical Engineering, the research group instead opted to use plasma technology that could carry an electrical charge to the surface of the printed part. Utilizing this technique, electric currents were able to pass through the 3D printed part, heating the nanotubes and welding the layers together.

Texas A&M and Essentium researchers have facilitated this process by adding both the plasma technology and the carbon nanotube-coated thermoplastic material components to conventional 3D printers. Upon testing the strength of 3D printed parts using their new technology, the researchers found that it was comparable to injection-molded parts.

“The holy grail of 3D printing has been to get the strength of the 3D-printed part to match that of a molded part,” Green said. “In this study, we have successfully used localized heating to strengthen 3D-printed parts so that their mechanical properties now rival those of molded parts. With our technology, users can now print a custom part, like an individually tailored prosthetic, and this heat-treated part will be much stronger than before.”

Research into mproving FDM

Research on this project began as early as 2017, when 3D Printing Industry first reported on the collaboration between Texas A&M University and Essentium to improve the strength of FDM 3D printed parts.

Since then, a number of researchers have also developed studies examining the different ways that FDM 3D printing can be enhanced. In late 2019, researchers at the University of Hamburg in Germany proposed a novel way of slicing 3D printed objects to create smoother results. By 3D printing nonplanar layers close to the horizontal, this slicing method removes the stair-stepping effect typical to FDM surfaces.

Another paper also explores the necessary improvements that material extrusion‐based additive manufacturing methods (ME-AM/FDM/FFF) need to make in order to “meet the challenges of complex industrial applications.” In particular, the researchers focus on improving the technology’s ability to process polypropylene (PP).

The study discussed in this article, “Dielectric Barrier Discharge Applicator for Heating Carbon Nanotube-Loaded Interfaces and Enhancing 3D-Printed Bond Strength”, is published in the journal Nano Letters. It is written by C. B. Sweeney, Matthew L. Burnette, Martin J. Pospisil, Smit A. Shah, Muhammad Anas, Blake R. Teipel, Bryan S. ZahnerBryan S. Zahner, David Staack, and Micah J. Green.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.