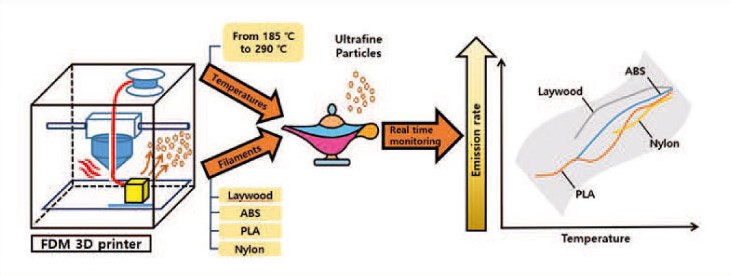

A recent study by researchers from Seoul National University investigates the effect of nozzle temperature on the emission rates of hazardous particles during FFF 3D printing. The scientists tested four different common polymer filaments and measured the concentration of particles with direct-reading instruments at various temperature intervals. The work aims to demonstrate that nozzle temperature is a key factor when it comes to safely operating an FFF system.

Ultrafine particle emissions

According to the study, systematic academic work on the topic of 3D printing emissions is limited. Previous research has already established that high levels of ultrafine particles, volatile organic compounds (VOCs), and aldehydes or carbonyls are emitted, especially at higher temperatures, but a quantified version of the information is not as widespread as it should be. If these emissions are inhaled, they can make their way into the pulmonary region of the lung and transfer over into the cardiovascular system, polluting the bloodstream.

Furthermore, temperature is not the only factor affecting the level of emissions during the printing process. The design of the printhead and the polymer used can also be major contributors, so manufacturer warnings should always be taken into consideration when operating a 3D printer.

Determining the emission rates

The research team first set up an enclosed chamber – where the printing would take place – to accurately measure the emissions produced. Each filament type (PLA, ABS, laywood, and nylon) was used to produce eight individual simple cube parts at varying temperatures. The nozzle temperatures ranged from 185°C – 290°C at 15°C intervals. Each filament was weighed pre- and post-printing to later calculate the emission rate relative to the mass of filament used.

The scientists used a scanning mobility particle sizer and optical particle spectrometer at one minute intervals to monitor the emissions in real time at each temperature. Each experiment was repeated three times the particle number per unit volume, along with the size distribution of the particles, was calculated. From these values the researchers could determine the emission rates for each material at each temperature.

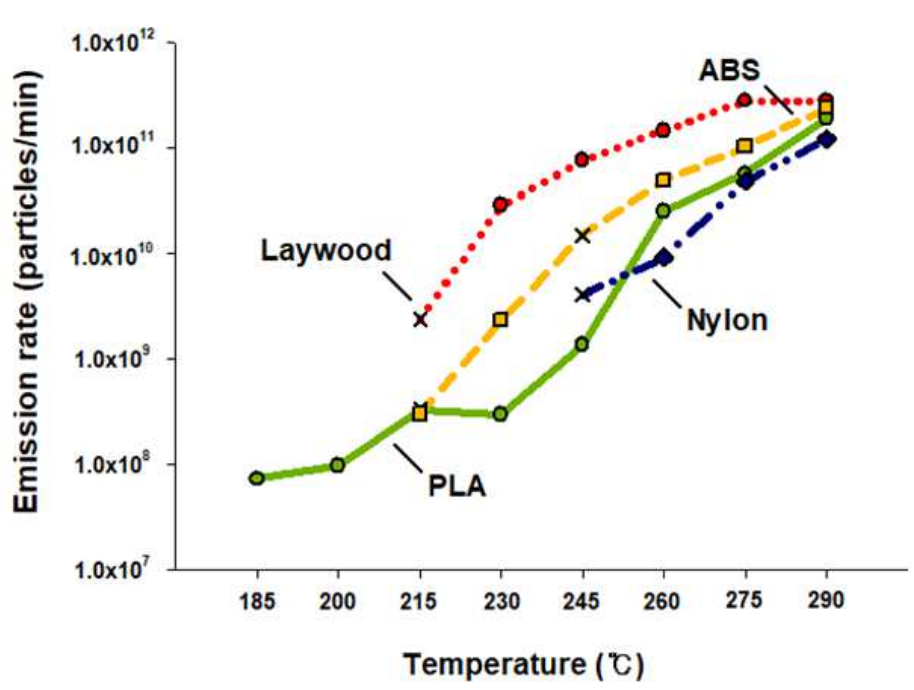

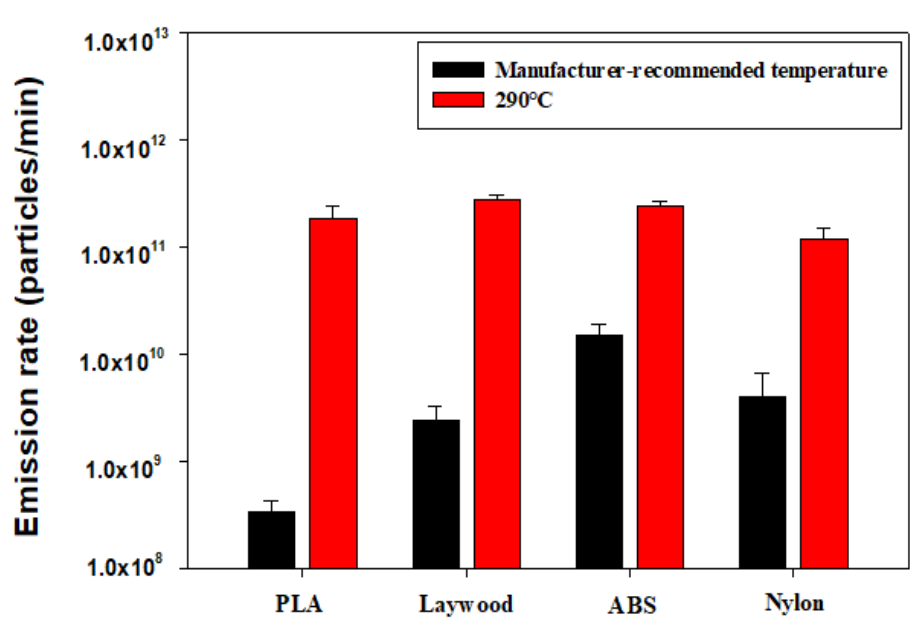

The researchers found that the emission rates of the harmful particles increased with every temperature interval for all four polymer types – a strong direct correlation. The filaments displayed emission rates of around 107 – 109 particles/min at the lowest temperatures, but 1011 particles/min at the highest temperatures. Comparing the two, the higher temperatures had emission rates up to 10,000x higher than the lower temperatures. It is therefore recommended that FFF printers be operated at the lowest possible temperature for the material being used.

Further details of the study can be found in the paper titled ‘Effect of nozzle temperature on the emission rate of ultrafine particles during 3D printing’. It is co-authored by Haejoon Jeon, Jihoon Park, Sunju Kim, Kyungho Park, and Chungsik Yoon.

In line with the results of the study, NIOSH recently published two new posters regarding 3D printing material safety for the workplace. The first poster covers steps that can be taken to ensure safe FFF printer operation and the second covers proper metal powder handling. Elsewhere, RadTech published a material handling health and safety poster for 3D printing resins.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a 3D printfarm. Photo via Prusa Research.