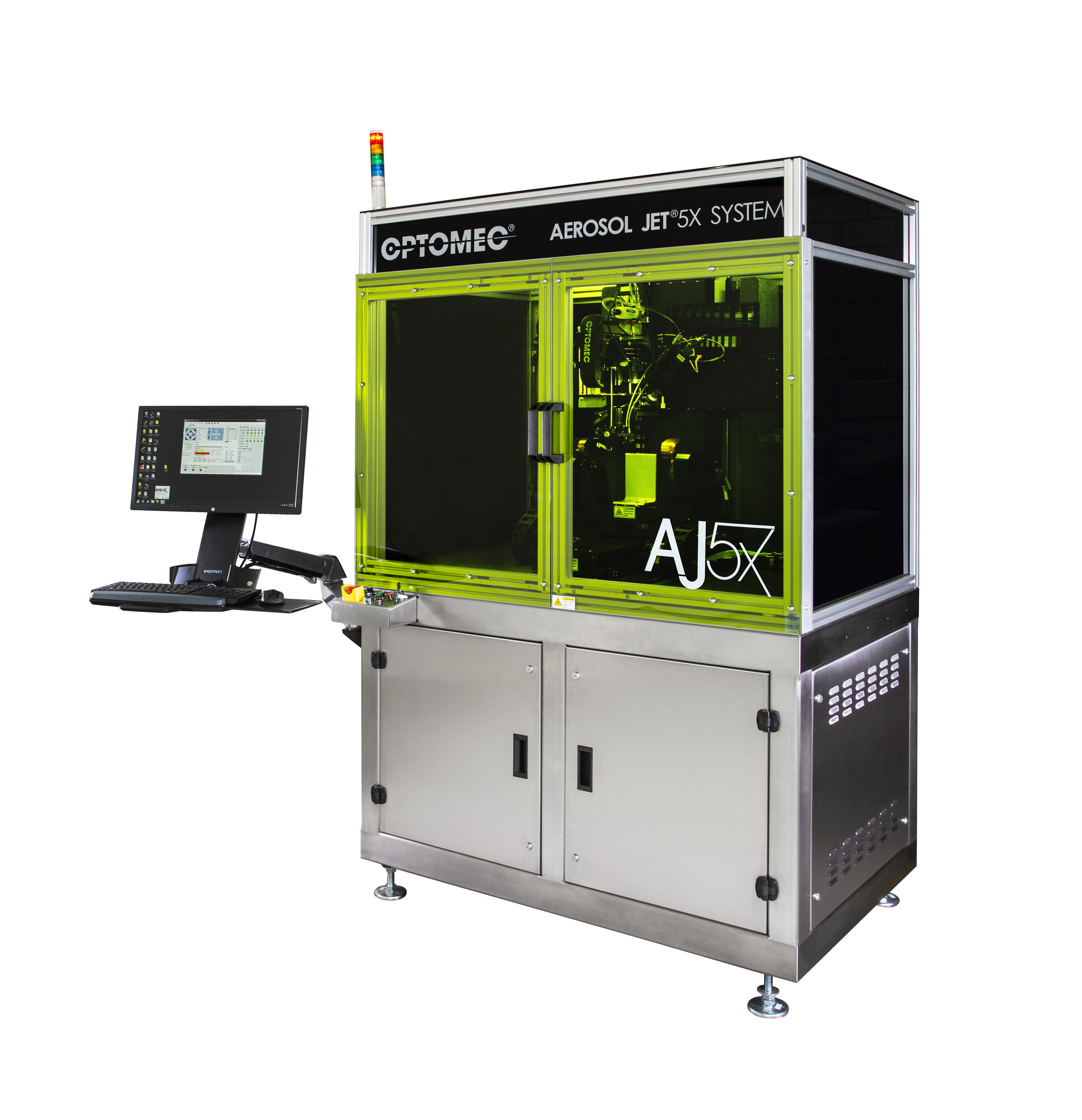

Samsung Electronics is enabling next-generation electronics production with the commission of an Aerosol Jet 5X System from New Mexico metal additive manufacturing specialist Optomec.

This 5-axis system is equipped with advanced vision and process controls and is designed to produce 3D printed electronics such as antennas, sensors, and Molded Interconnect Devices (MIDs) with features ranging from 10 microns to millimeters.

Aerosol Jet Printing technology

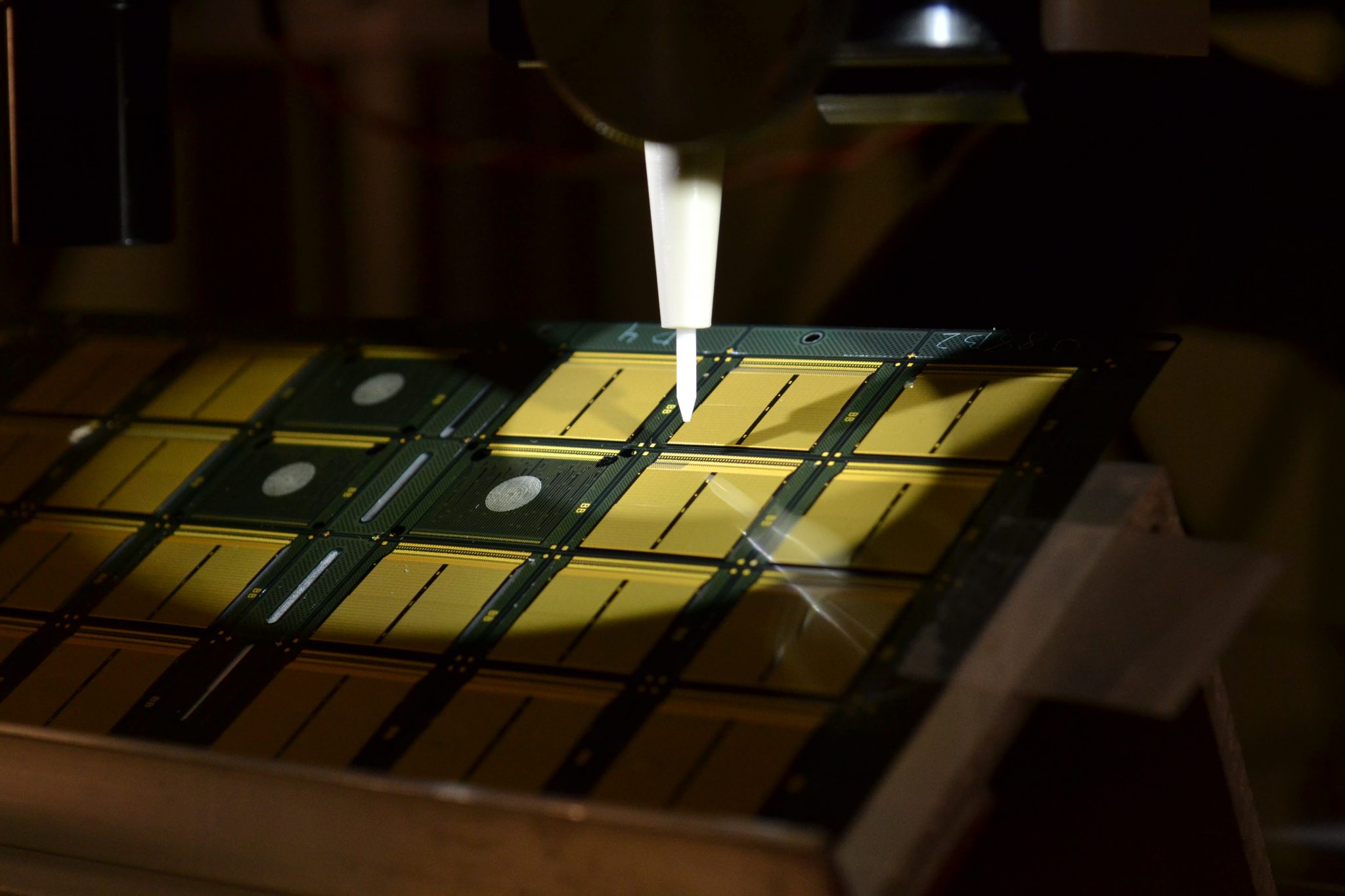

Optomec’s Aerosol Jet Printing (AJP) is a technique for manufacturing interconnects on both 2D and 3D substrates. This eliminates the need for wire bonding – for example, printing electrical connections on 3D stacked die or for LED chip fabrication. Furthermore, a print module is integrated into AJP systems for high-resolution electronic circuits and devices for rapid prototyping, product development, and low volume production.

The AJP process forms structures using small ink like droplets of metals. The company is also the creator of LENS 3D printing technique that uses lasers to sinter metal powders. Earlier this year, Optomec released new standalone systems with this technology, the LENS CS 600 and CS 800.

As a result of its technologies, Optomec’s customer portfolio includes GE, Boeing, and the aircraft manufacturer, United Technologies, the Additive Manufacturing Facility of ARDEC, University of Nebraska, NASA, and the Air Force Research Laboratory.

3D printed electronics

Previously, a team at Draper Laboratory, based in Massachusetts, replicated a part of a wireless Bluetooth transceiver with an Optomec aerosol jet printer. In addition, researchers from Washington State University 3D printed structures resembling the intricate framework of a natural desert rose with AJP technology.

Elsewhere, Samsung Electronics has ventured into additive manufacturing through a collaboration with Energica, the manufacturer of the Energica Ego – Italy’s first street-legal electric motorcycle with 3D printed parts. The partners’ Smart Ride Project led to the development of the Bolid-E motorcycle which includes 3D printed components such as front and back headlights and tail light supports.

For more additive manufacturing news subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.

Featured image shows Aerosol jet printed part of a Bluetooth microprocessor. Photo via Draper Laboratory.