NASA, the US civilian space program, continues to bring excitement to 3D printing geeks everywhere. As a lover of all things Star Trek, a food replicator has always been on my short-list, so I have high hopes for NASA’s 3D pizza printer. Now, they are investigating aerosol jet printing, or direct-write manufacturing, to create small electronic board assemblies. And once again, additive manufacturing will bring production time down from a month to a mere day or two.

Aeorosol Jet Printing enables 3D Printed electronics

“Aerosol Jet printing technology prints commercially-available conductive, dielectric, semiconductor and biologic inks onto a variety of 2D or 3D plastic, ceramic, and metallic substrates. The result is 3D digital printing that eliminates the need for hard tooling photomasks or stencils and enables engineering changes to be quickly implemented by simply modifying the design file,” says OPTOMEC, a commercial developer of these direct-write printers. The aerosol spray deposits extremely fine lines, as small as ten microns wide, smaller than a thread from a silkworm cocoon. And, as Paquette says, “It can print around bends, on spheres or on something flat, or on a flexible surface, which then can be flexed into the shape you want.”

Electronic components such as resistors, capacitors, antennas, sensors, and thin film transistors have all been printed with Aerosol Jet technology. The performance parameters of printed components, for example the ohm value of a resistor, can be controlled through printing parameters. Components can also be printed onto 3 dimensional surfaces eliminating the need for a separate substrate thereby reducing the size, thickness and weight of the end product. For example, Aerosol Jet is used to print antennas and sensors that conform to the shape of the underlying substrate such as a cell phone case.

How the NASA is using the Aerosol Jet Printing

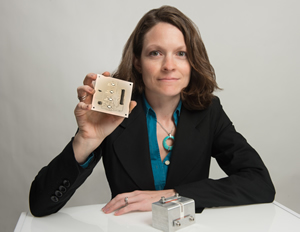

At the Goddard Space Center in Greenbelt, Maryland, NASA technologist Beth Paquette has created a 3-inch-by-3-inch ceramic board with four radiation-hardened digital-to-analog converter chips. The circuitry was generated with the aerosol jet printing technique using silver ink. As such detector assemblies become smaller and smaller, it becomes almost impossible to produce and put together the individual parts.

NASA expects they will soon be able to use aerosol jet technology to print hardware directly on to space craft. But I’m holding out for that 3D pizza printer.